NaN / 0

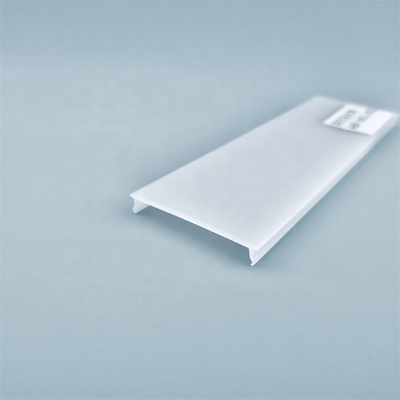

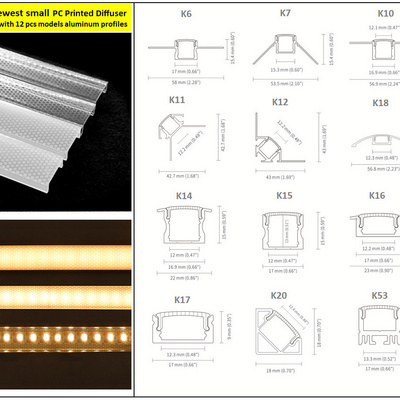

led diffuser lens PMMA frosted light linear light cover

Get Latest Price

US$ 0.6

≥3000 Meters

US$ 0.5

≥5000 Meters

Quick Details

Warranty:

1 Year

After-sale Service:

Online technical support

Project Solution Capability:

graphic design

Application:

Apartment

Product Details

Product Description

|

Product Features

|

|

|

|

*Product Code

|

sld20170518-001zly

|

|

|

*Material

|

PMMA

|

|

|

*Size

|

Customized by drawing or samples.

|

|

|

*Style

|

Plastic extrusion process

|

|

|

*MOQ

|

500KGS

|

|

|

*Brand

|

CSSSLD

|

|

|

*Origin

|

China

|

|

|

*Thickness

|

1mm--Customized

|

|

|

*Production ability

|

200kg /day / machine.

|

|

|

*Length

|

Any length as you required

|

|

|

*Surface Treatment

|

Do any color by Panton or RAL color number; Painting; Film coating; Electro galvanizing and so on.

|

|

|

*Post Process

|

Punching; Dig holes; Angle or Special Cutting; Machining and so on.

|

|

|

*Surface

|

Glossy

|

|

|

*Mold & Sample production time

|

20-30 Days

|

|

|

*Packaging

|

Custom carton, wooven bags, pallet

|

|

|

*Shipping Port

|

Shanghai or Ningbo Port

|

|

|

*Payment

|

30% T/T in advance, the balance will be paid before shipping.,Western Union or T/T

|

|

Facade

B

ackside

Detailed Images

-

-

Nice surface with unobviously extrusion lines

-

Clip on the aluminum profile, easy to assebling.

-

Any color and length is available

Company Introduction

Changshu

Shunlida Plastic Product Factory found in 1997, located in Changshu city, Jiangsu, China. Which is specialize in plastic plastic extrusion and injection custom products, and increased the rubber moulding production for five years already.

Our factory have more than 22 years customizing experiences in plastic profile, injection parts with materials such as (PVC, ABS, PC, PP, PE, PS, ACRYLIC, POM, NYLON, PBT, PET, TPU, TPE, TPV, PPS etc.), and Rubber components with material (NR, NBR, SILICONE, EPDM etc.). Provide one-stop services to our customers.

We have a matured factory structure including Designing Dept. Molds Dept. Production Dept. QC Dept. Sales Dept. And warehouse Dept. All of them are well connected and mutual support for each other.

During passed 22 years, we have increased and weeded out many machines to meet the technical advances every year. Now we have 15 effective extrusion lines and 5 advanced automatic injection machines in 5000sqm workshop and around 50 experienced workers.

We provide customized service including designing products, initial 3D or CNC prototypes, in-house tooling production, mature goods production, custom after production process (special cutting, drilling, punching, printing, painting, plating, assembling etc. ).

CSSSLD have accumulated over 500 customers from all over the world since founding. With the continuous growing technical, satisfied nearly all of them with our good products and services. And build many long fruitful cooperation.

We believe our innovation and integrity will keep us and customers growing together and better. Sincerely welcome to contact and visit our factory.

Plastic Extrusion Workshop

Plastic Injection Workshop

Plastic Mold, Tooling, Die

Samples Room Show

Raw Material Stock

Goods Stock

Our Advantages

CSSSLD provide on-stop custom plastic product service Including professional Design, Develop, skilled manufacturing, active service and effective feedback.

SERVICE:

PLANING & DESIGN:

Concept discussion. Own design team can help you from concept to product

design.Do feasibility analysis before develop. Design various kinds of molds to make product true.

design.Do feasibility analysis before develop. Design various kinds of molds to make product true.

DEVELOP:

Suggestion and confirm the Raw material.SGS,ROSH,MSDS or other specifications approved per customer requested. 3D or CNC prototypes to check first before

design confirmed(optional). Extrusion, injection or rubber mould and tools developing by CSSSLD.

MANUFACTURING:

Samples approved, mass production according to it. Sufficient raw material stocks sustain smoothly production and control the steady cost. Effective inspection during and after production control the defective rate below 2%. Custom good packing for all kinds of custom goods.

SERVICE:

Cost-effective for good delivery service (optional). Continuous to following up, active and effective feedback solutions

service.

service.

Certifications

Customer Photos

Product packaging

FAQ

How To Place An Order ?

1. Inquiry send requrements to CSSSLD

2. Received CSSSLD quick and professional quotation.

3. Confirm price, lead time, artwork, payment term etc.

4. CSSSLD sales send Proforma Invoice for payment. And comfirm it after paid.

5. Initial Production Stage: sales send CSSSLD technical drawing for customer to confirm. Then begin mould production.

when mould finished, make samples according to your request, send you photo or sample to approve,

6. Middle Production Stage: After sample approved, then make mass production, send pohotes to show the production situation,

confirm the estimated delivery time.

7. End Production Stage: send production phote or random samples to you, You can also arrange the third party to do inspection.

8. Clients make the payment and CSSSLD ship the goods. Also can accept payment term against copy of B/L. Checking shipping status

for clients.

2. Received CSSSLD quick and professional quotation.

3. Confirm price, lead time, artwork, payment term etc.

4. CSSSLD sales send Proforma Invoice for payment. And comfirm it after paid.

5. Initial Production Stage: sales send CSSSLD technical drawing for customer to confirm. Then begin mould production.

when mould finished, make samples according to your request, send you photo or sample to approve,

6. Middle Production Stage: After sample approved, then make mass production, send pohotes to show the production situation,

confirm the estimated delivery time.

7. End Production Stage: send production phote or random samples to you, You can also arrange the third party to do inspection.

8. Clients make the payment and CSSSLD ship the goods. Also can accept payment term against copy of B/L. Checking shipping status

for clients.

Hot Searches