NaN / 0

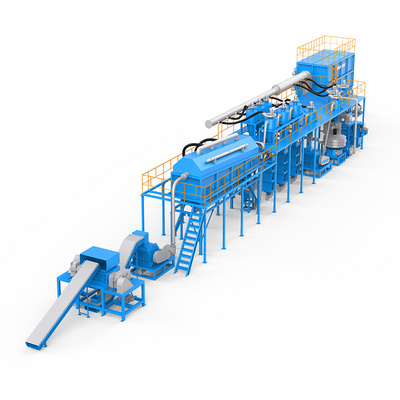

Manufacturer Waste Mobile Phone Battery Lithium Batteries Recycling Machine

Get Latest Price

US$ 30000

≥1 Sets

Quick Details

Production Capacity:

300-2000T/H

Place of Origin:

Henan, China

Brand Name:

HONEST

Model Number:

HNLDC300-2000

Product Details

BACKGROUND

Lithium battery mainly consists of shell, positive electrode, negative electrode, electrolyte anddiaphragm. The positive electrode is formed by coating lithium cobaltate powder on two sides ofan aluminum foil current collector through PVDF which plays a bonding role;The negative

electrode structure is similar to the positive electrode and consists of carbon powder bonded toboth sides of the copper foil current collector. At present, the research on the recycling of wastelithium batteries is mainly focused on the recovery of high-value anode precious metals cobaltand lithium. Copper in the negative electrode of waste lithium battery (content up to 35%) is animportant production raw material widely used.Carbon powder adhered to it can be used asadditives such as plastics and rubber. Based on the structural characteristics of lithium batteries,our company adopts an environmentally-friendly physical separation process to realize efficientseparation and recovery of waste lithium batteries.

RAW MATERIALS

The lithium battery recycling production line is used for dismantling andrecycling the Soft pack-age battery, cellphone battery, Shell battery,Cylindrical battery etc. Different types of lithium bat-teries have different recycling procedures. Please contact us for detailed configuration.

Products Description

The pretreatment process of waste lithium ion batteries mainly comprises the following steps:

afterdischarging the recovered waste batteries, crushing, magnetic separation, air separation,crushing, gravity separation, screening and other processes are carried out by mechanical equipment,so that the powder on the positive and negative pole pieces is effectively separated from thecopper aluminum foil,

and the batteries are treated as valuable materials.

FINAL PRODUCTS

The final products of this plant is Graphite powder, Cobalt acid lithium,Aluminum and copper.

TECHNOLOGICAL PROCESS

Shredder:

Shredded lithium batteries into smaller pieces.

Hammer crusher:

For the secondary crushing of shredded materials.

Grinder:

For the grinding of the crushed materials.

Separation machine:

Separate the materials after being ground.

Collector:

Collect and release the dust .

Pulse purifier (air cleaner):

Clean all the dust produced during the operation of the wholesystem.

Classifying screen:

Screen the materials sorted by the separation machine,and screen out oflarger metal materials.

Magnetic machine:

Separate nickel from the metals.

Gravity separator:

Separate those finer materials got from the screening machine and separatethe metal completely.

High-pressure blower:

Keep the whole system in a negative state so as to collect the materialsand purity the air .

Environmentally friendly recycling equipment

The air purification equipment of this production line has a very good performance.There are water spray facility and activated carbon device used to absorb odors andpulse dust collection system for dust adsorption.

TECHNICAL PARAMETERS

|

Model

|

Capacity

|

|

|

LDC-300

|

200-300 Kg/H

|

|

|

LDC-500

|

500 Kg/H

|

|

|

LDC-800

|

800 Kg/H

|

|

|

LDC-1000

|

1T/H

|

|

|

LDC-1500

|

1.5T/H

|

|

|

LDC-2000

|

2T/H

|

|

|

WORKING PERFORMANCE

|

|

|

|

Raw Material

|

Lithium Battery

|

|

|

Final Product

|

Mainly Copper, Aluminum, Lithium Cobalt Oxide, Graphite Powder

|

|

TECHNICAL STANDARDS

|

Feature Item

|

Indicator Requirments

|

|

Recovery Rate of Metallic Aluminum

|

>98%

|

|

Powder Recovery Rate

|

>98%

|

|

Content of Powder In Metal Aluminum

|

<2%

|

|

Content of Metallic Aluminum In Powder

|

<2%

|

|

Other

|

Contain dust collecter with not pollute

|

|

Qualified Rate

|

99%

|

|

Failure Rate

|

<1%

|

|

CMR

|

≥1.67

|

Delivery

Quality Assurance

Company Show

Our Company has advanced technology, professional R&D team and perfect sales service system. Besides, we possess several patents and domestically-leading technologies. Our advanced equipment have been currently exported to USA, Spain, Turkey, Italy, Vietnam,Hungary, Australia, Korea, Malaysia, Singapore, India, Philippines, Ireland, Saudi Arabia, Dubai etc.

Hot Searches