NaN / 0

XPS Board Modle XPS Extruded Polystyrene Foam Sheet

Get Latest Price

US$ 1

≥1 Pieces

Quick Details

Warranty:

More than 5 years

After-sale Service:

Online technical support

Project Solution Capability:

total solution for projects

Application:

Hotel, Villa, Apartment, Office Building, Hospital, School, Mall, Sports Venues, Supermarket, Warehouse, Workshop, Courtyard

Product Details

Product Description

XPS Board Modle XPS Extruded Polystyrene Foam Sheet

XPS is an extruded polystyrene insulation manufactured through a plastic extrusion process. The resulting boards are almost 100% closed cell, strong, highly moisture resistant and easy to cut and shape.

XPS foam board widely used in wall insulation, low-temperature storage facilities, parking platform, the airport runway, construction of concrete roof and the structure of the roof, highways and other areas of moisture-proof enexpensive industry material.

We promise for Tyco 100% fresh material, whether it's fireproof or not, its

totally environment friendly

, safe to human being and environment, free of HBCD.

PS: HBCD (hexabromocyclododecan), HBCD as a widely used fire resistant in xps insulation field, is forbidden in Europe from March, 2016, so we change formulation use another environment friendly fire resistant to produce board, it's safe. (With SGS report)

Characteristics

* Stable performance and anti-aging: The extruded polystyrene(xps) insulation boards can be used 35-50 years.

* Resistance to compression: compared with other thermal insulation material(200kpa for EPS), it has better compressive strength (around 300kpa), which make it the ideal solution for heavy domestic or industrial loads.

* Water resistance: Polyfoam is almost 100% closed cell and as such is unaffected by moisture.

* Lightweight: volume optimization and easy to handle

* Resistance to deformation

* Resistance to impact

* Versatile: the closed cell structure and density of polyfoam allow specific edfe details and surface finishes to be cut into the boards to make them as fit for the job as possible. Moreover, Polyfoam can be cut into almost any shape.

* Polyfoam can be 100% recycled

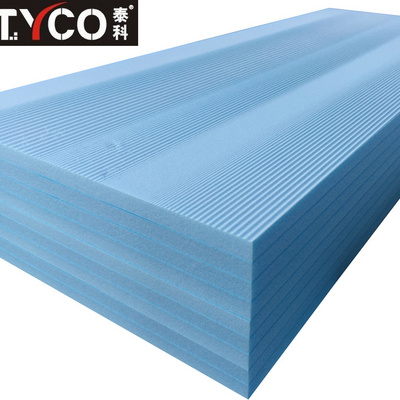

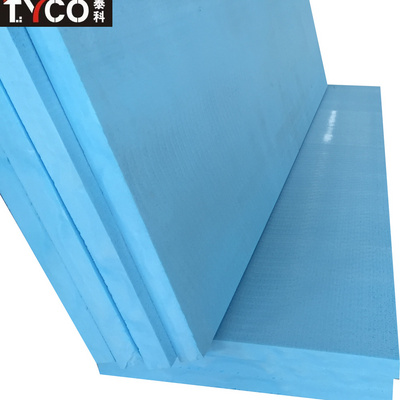

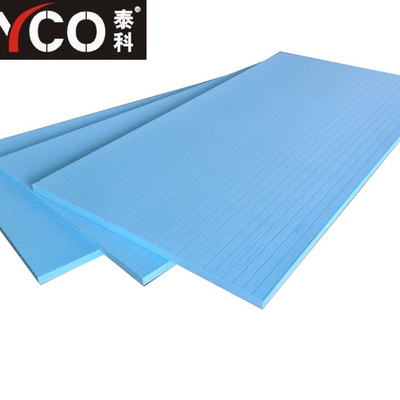

Two Different Surfaces of XPS Board Modle XPS Extruded Polystyrene Foam Sheet

We can support two different surfaces, with skin the tolerance is ±2mm, without skin the tolerance is ±0.02mm.

When XPS foam panel without skin used on floor, the floor will be more flat than use with skin panel.

When XPS foam panel without skin used on wall, the panel can be more easily installed and lay tiles more efficiently.

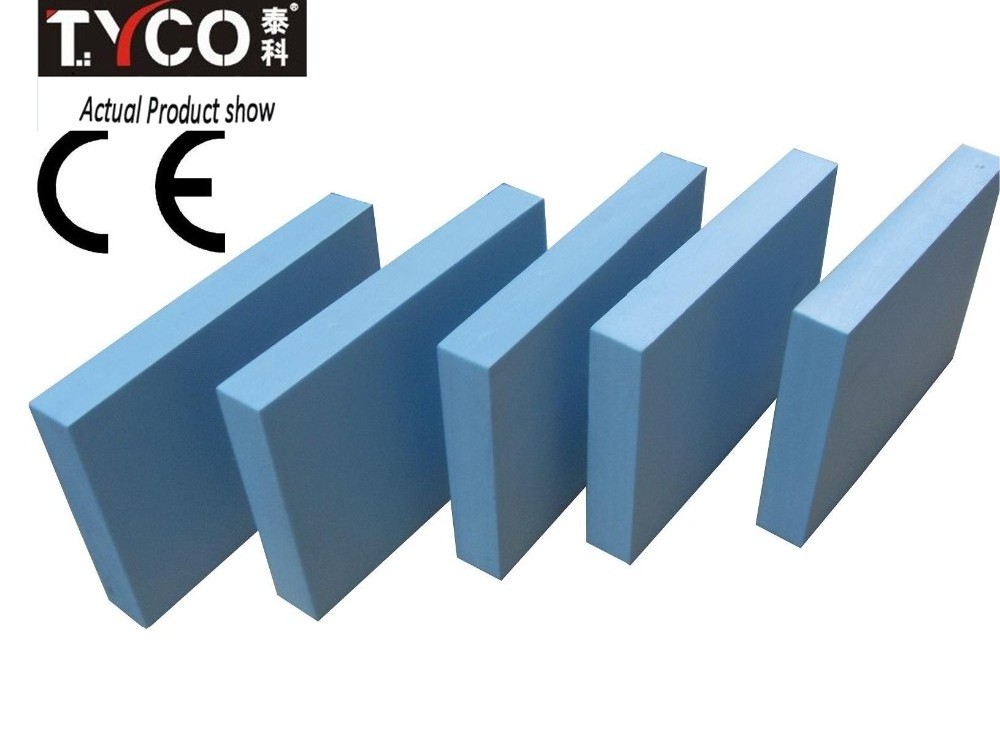

Three Types of Lap Jointing of XPS Board Modle XPS Extruded Polystyrene Foam Sheet

Technical Data Of XPS Foam Board

|

Density

|

Kg/m3

|

30-45

|

|

Thermal conductivity,90days,10℃

|

W/(m*k)

|

0.027-0.036

|

|

Compressive strength at 10% deflection or yield,(vertical)

|

Kpa

|

250-700

|

|

Tensile strength

|

kpa

|

≥350

|

|

Water absorption

|

Vol-%

|

≤1.00%

|

|

Capilarity

|

nil

|

nil

|

|

Coefficient of linear thermal expansion

|

mm(m*K)

|

0.07

|

|

Temperature limits

|

℃

|

-50℃,+75℃

|

Available Sizes:

|

Thickness

|

Width

|

Length

|

Edge

|

|

60-100mm

|

600mm

|

|

Square Edge

|

|

20-100mm

|

600mm

|

|

Ship Lap,

Square Edge,

Tongue&Grooved

|

|

20-100mm

|

900mm

|

|

|

|

20-100mm

|

1200mm

|

|

|

Note:

XPS is foamed by environment gas and fire resistant with HBCD

Other sizes, surface or edge could be produced accordingly

XPS foam board characteristics

* Thermally insulating

* Waterproof and dimensionally stable

* Low weight, one board (1200 x 600x 10mm) is around 1.8kg

* Easy to cut( by knife or saw)

* Excellent for wet rooms

* Excellent sound insulation(12mm board,20 db)

* Environment friendly ( Free of CFC & HCFC)

* Easy to be tiled

Application

* Building exterior insulation

* Cold storage: exterior wall insulation, inner wall insulation, roof insulation, floor insulation

* Waterpower concrete aqueduct

* Airport runway and highway

* Central air-conditioning ventilation

* Cold storage: exterior wall insulation, inner wall insulation, roof insulation, floor insulation

* Waterpower concrete aqueduct

* Airport runway and highway

* Central air-conditioning ventilation

It is easy and quick to installed and can be finished with tiles to match surrounding decoration.

Can be made to any size, excellent for waterproof and heat and sound insulation.

Can be used in bathroom and wall and wet room.Easy installation can save cost and time.

You can installed by yourself.

Packing & Delivery

Our Company

Our Certifications

FAQ

1. Are you the factory or trading company?

2.Can you change the color like white , yellow or green.

A:Yes, we can produce Moisture-resistant Rigid Foam Board with required color, for that the MOQ is 200CBM.

3.Does the Moisture-resistant Rigid foam board you produce is environment friendly or Green product?

A:Yes, the Rigid foam board we produce is free of CFC and HCFC.

4.What is the MOQ of Moisture-resistant Rigid Foam Board ?

5.Can I mix different designs?

A:Sure, Other sizes,surface or edge could be produced accordingly .

6.Can I get a lower price if I place a large order of Moisture-resistant Rigid Foam Board?

A:Yes, cheaper prices with larger orders.

7.Can I get the pre-production sample ?

A:Yes, we will send you sample for refer and start the production after you confirmed.

8.How about the delivery date?

A:In stock items:2-5 days after payment

Custom Design Items: 7-15days after payment

A:Yes, we will send you sample for refer and start the production after you confirmed.

8.How about the delivery date?

A:In stock items:2-5 days after payment

Custom Design Items: 7-15days after payment

Hot Searches