NaN / 0

High quality XPS extruded polystyrene foam board, XPS styrofoam sheet for heat insulation

Get Latest Price

US$ 60

≥60 Cubic meter

Quick Details

Warranty:

1 Year

After-sale Service:

Online technical support, Onsite Training

Project Solution Capability:

total solution for projects

Application:

Storage & Closet

Product Details

Product Description

XPS board type styrofoam sheet waterproof for building

Environmental-friendly Poystyrene XPS foam board type styrofoam sheet without HCFC

XPS foam insulation board process :Polystyrene Granule, Talcum Powder, Master batch, Blowing Agent , and fire retardant are mixed and melted in Extruder. The melt material will be extruded out of Slot Die, then through Calibrator for forming the panel shap. After cooling, cutting, edge trimming, packaged to finished product.

XPS board feature:

1, Good Heat insulation, energy saving and environmental protection

Unique extrusion production process to create obturator rate is as high as more than 99% of the closed cell structure, has high heat resistance, low linear, expansion ratio characteristics of low, cut off the flow of cooling air, effectively prevent heat conduction, ensure that the insulation performance of lasting and stable.

2, Water-proof, stable performance

Characteristics of XPS internal obturator honeycomb structure and polystyrene molecule itself does not absorb water, effectively prevent the penetration and the spread of water molecules, effectively avoid the disadvantage of leaking, penetration, frost and condensation caused by plate decomposition aging of other similar material..

3, High compressive strength, superior impact

Unique molecular arrangement and the stability of foam pore structure, make its high compressive strength, impact resistance, strong, according to XPS of different type and thickness of the compressive strength of up to more than 150~800Kpa, under various system loads on the ground.

4, Long-service life, excellence quality

Polystyrene itself has extremely stable chemical properties, resist aging after long time use.It does not produce harmful substances decomposition, good quality of water-proof and anti-moisture can ensure that even under very high&low temperature environment it can still maintain its superior performance.

2, Water-proof, stable performance

Characteristics of XPS internal obturator honeycomb structure and polystyrene molecule itself does not absorb water, effectively prevent the penetration and the spread of water molecules, effectively avoid the disadvantage of leaking, penetration, frost and condensation caused by plate decomposition aging of other similar material..

3, High compressive strength, superior impact

Unique molecular arrangement and the stability of foam pore structure, make its high compressive strength, impact resistance, strong, according to XPS of different type and thickness of the compressive strength of up to more than 150~800Kpa, under various system loads on the ground.

4, Long-service life, excellence quality

Polystyrene itself has extremely stable chemical properties, resist aging after long time use.It does not produce harmful substances decomposition, good quality of water-proof and anti-moisture can ensure that even under very high&low temperature environment it can still maintain its superior performance.

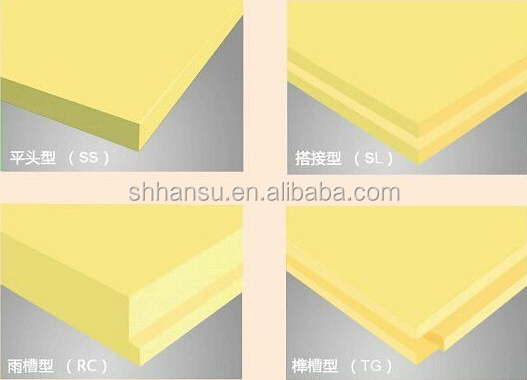

XPS Edge and surface type.

Our equipment

Euiqpment and technolgoy guarantee the Perfect quality of XPS product

Our XPS prouciton line is from our own machinery company-Hansu Plastic Machinery Co.,Ltd , specialized in XPS machinery and technology since 2007. Thus, with the good guaranteed production line and core foaming technology of XPS product, can help us achive the perfect quality of XPS product.

Delivery

Storage

Our company

We are the manufacturer, specialized in XPS.

We have Hansu machinery company for XPS production line ,and we also have our own factory for XPS foam board.

1.Our

brother company

focused on the foaming technology of XPS production line since 2007. And the first XPS production line with CO2 foaming was successfully developed in 2009 and exported to Turkey. This production line is still well operated.

3. Since our machinery company established, we have supplied

more than 20 units

of XPS production line

with CO2 foaming

to domestic and overseas market and supplied the whole technical support for our customers. We have gathered a rich experience of the technical processing of the CO2 foaming production line.

4.

We are generated from

HANSU MACHINERY, HANSU ENERGY SAVING company

for XPS product

is established at the beginning of 2016.

5. We can show you our own working line for you during your visit.

Hot Searches