NaN / 0

3D car mats Thick sheet vacuum forming machine

Get Latest Price

US$ 30000

≥1 Sets

Quick Details

Max.Forming Height(mm):

650 mm

Forming Width (mm):

1000 mm

Forming Length (mm):

1500 mm

Heating Power (kW):

38 kW

Product Details

Thick sheet vacuum forming machine

The machine is used in PS/PP/PET etc. vacuum forming

1)By relay under auto mode

2)High capacity

3)Environmentally friendly

Suitable for industry:

Suitable for industry:

1. PC,ABS and PE luggage forming;

2. Car and motor parts forming;

3.Plastic tray or turnover pallet;

4. Refrigerator inner case;

5.3D car mats;

6.The plastic products which thickness is more than 1mm;

Remarks:

Remarks:

The forming size is customizable;

The max. forming size is 2500*2000*800mm;

•Suitable Rubbers:PS,PE,ABS,PC,Acrylic...etc plastic materials above 2mm.

•Suitable Products:Inner and outer linings of refrigerators,bathtubs,cosmetic boxes,travel baggage,automobile parts,aircraft parts,fitness equipment and various general industrial big-scale products.

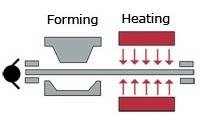

Schematic diagram

Products samples

Technical Data TVF series

Technical Data TVF series

|

Model |

TVF-1510 |

TVF-2015 |

TVF2515 |

|

Suitable material |

PP, PE, PS, PVC, PET, ABS, HIPS, Acrylic degraded material, etc. |

||

|

Forming thickness |

2-8mm for upper oven, 2-10mm for double ovens |

||

|

Forming length |

1500mm |

2000mm |

2500mm |

|

Forming width |

1000mm |

1500mm |

1500mm |

|

Forming height |

650mm |

||

|

Max. forming sheet |

1600*1100mm |

2100*1600mm |

2600*1500mm |

|

Heater consumption |

400W*96pcs |

400W*192pcs |

400W*240pcs |

|

Power supply |

380VAC/3phase/50Hz; 220VAC/3phase/60Hz; |

||

|

Vacuum pump |

100m3/H |

160m3/H |

|

|

Production Capacity |

1-4mins/T |

||

|

Air pressure |

0.6-0.8Mpa |

||

|

Machine size(L*W*H) |

3890*1850*3400mm |

4200*2250*3400mm |

5000*2250*3400mm |

|

Weight |

About 5300kg |

About 5700kg |

About 6500kg |

Those models are standard and controlled by relay, can be changed to PLC and touch to control;

Full control of electrical :"OMRON" made in Janpan

Air cylinder:"Zhicheng" made in China

Solenoid pilot actuated valve:"Airtac" made in Taiwan

Radiator:"SME" made in China

Travel switch:"Panasonic" made in Janpan

Auxiliary equipment or component

Vacuum pump: “Becker” Germany

Industrial Chiller:"SME" China

The main component

Timer and relay: "OMRON" Taiwan

Infrared ceramic heater: "SME" China

Temperature control: "TCL" stepless fine-tuning China

AC contactor: "Schneider" France

Cold-water atomizer: "Prona" Taiwan

Cylinder: "Zhicheng" China or "Airtac" Taiwan

Solenoid pilot actuated valve: "Zhicheng" or "XMC" China

Air treatment component: "Zhicheng" or "XMC" China

Auxiliary equipment or component

Vacuum pump: “Becker” Germany

Industrial Chiller: "SME" China

Special Function

1. Twice vacuum function

2. Twice top die

3. Twice demould

4. Manual demould

5. Vacuum delay

6. Aerodynamic fine-tuning function

7. Sheet frame moving by the cylinder

8. Blow sheet in advance

9. Top die can be adjusted by the motor

10. Add the oleo damper reduce the sheet frame moving

Remarks: The price is non-including the mold cost.

Payment Terms: T/T 40% deposit before production, 60% balance against b/l copy;

Delivery time: 35-40 business days after deposit;

Validity: 30 days after quote.

Departure Port: Guangzhou Huangpu port Packing: wooden block

Warranty: We guarantee these machines for one year. And we supply some spare parts with the machine, operation manual and operation CD, etc.

Service: We will send engineer who install and train in your company for approximately 7 to 10 days, after machine is arrived your place. And the flight tickets, visa and accommodation of engineer will be arranged by buyer, also the buyer need pay 50USD/day for training cost.

Because we are the manufactoy, we can design the machine as the customer's requirement. Please send more details about your products.

Hot Searches