NaN / 0

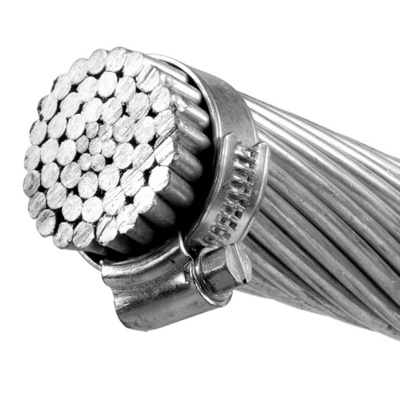

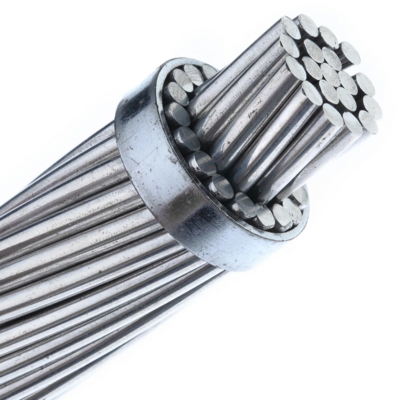

ACSR/AAC/ AAAC/Aluminium Bare Conductor Aluminium Overhead Conductors

Get Latest Price

US$ 0.1

≥100 Meters

Quick Details

Insulation Material:

Bare

Application:

Construction

Conductor Material:

Aluminum

Jacket:

Bare

Product Details

Product Description

ACSR/AAC/ AAAC/Aluminium Bare Conductor Aluminium Overhead Conductors

Brief Description:

This conductor is made from aluminium-magnesium silicon alloy of high electrical conductivity containing enough magnesium silicide to give it better mechanical properties after treatment. These conductors are generally made out of aluminium alloy 6201.

AAAC CONDUCTOR has a better corrosion resistance and better strength to weight ratio and improved electrical conductivity than ACSR CONDUCTOR on equal diameter basis.

Applications:

AAAC aluminum alloy conductors are extensively used for overhead distribution and transmission lines adjacent to ocean coastlines where there can be a problem of corrosion in the steel of an ACSR construction.The inductive effect of the ACSR's steel core is eliminated, hence increasing the operating efficiency of the line.

Features and Benefits:

Aluminum alloy conductors have a number of advantages over the use of the ACSR or all aluminum

conductors. Lower power losses than for equivalent single aluminum- layer ACSR conductors. (The inductive effect of the steel core in the ACSR is eliminated).

• Simpler fittings than those required for ACSR.

• Excellent corrosion resistance in environments conducive to galvanic corrosion in ACSR.

• Strength and sag approximately the same as for equivalent 6/1 and 26/7 ACSR conductors.

• Outside diameters are the same as for standard ACSR conductors, permitting interchangeability of fittings.

• Greater resistance to abrasion than that for 1350 wires in all-aluminum or ACSR conductors.

Key Benefits:

· High tensile strength as compared to AAC conductor.

· Higher conductivity as compared to ACSR conductor.

· Better corrosion resistance than ACSR conductor.

Physical contents of alluminium alloy :

· Density - 2.70 kgm/dm3 at 20°C

· Coefficient of Linear Expansion - 23 x 10-6 / °C

· Resistivity - 0.0326 Ohms mm2/m at 20°C

· Constant Mass Temperature Coefficient (a) - 0.00360/ °C

· Material - Heat treated Al. Mg. Si. Alloy

This conductor is made from aluminium-magnesium silicon alloy of high electrical conductivity containing enough magnesium silicide to give it better mechanical properties after treatment. These conductors are generally made out of aluminium alloy 6201.

AAAC CONDUCTOR has a better corrosion resistance and better strength to weight ratio and improved electrical conductivity than ACSR CONDUCTOR on equal diameter basis.

Applications:

AAAC aluminum alloy conductors are extensively used for overhead distribution and transmission lines adjacent to ocean coastlines where there can be a problem of corrosion in the steel of an ACSR construction.The inductive effect of the ACSR's steel core is eliminated, hence increasing the operating efficiency of the line.

Features and Benefits:

Aluminum alloy conductors have a number of advantages over the use of the ACSR or all aluminum

conductors. Lower power losses than for equivalent single aluminum- layer ACSR conductors. (The inductive effect of the steel core in the ACSR is eliminated).

• Simpler fittings than those required for ACSR.

• Excellent corrosion resistance in environments conducive to galvanic corrosion in ACSR.

• Strength and sag approximately the same as for equivalent 6/1 and 26/7 ACSR conductors.

• Outside diameters are the same as for standard ACSR conductors, permitting interchangeability of fittings.

• Greater resistance to abrasion than that for 1350 wires in all-aluminum or ACSR conductors.

Key Benefits:

· High tensile strength as compared to AAC conductor.

· Higher conductivity as compared to ACSR conductor.

· Better corrosion resistance than ACSR conductor.

Physical contents of alluminium alloy :

· Density - 2.70 kgm/dm3 at 20°C

· Coefficient of Linear Expansion - 23 x 10-6 / °C

· Resistivity - 0.0326 Ohms mm2/m at 20°C

· Constant Mass Temperature Coefficient (a) - 0.00360/ °C

· Material - Heat treated Al. Mg. Si. Alloy

|

All Aluminium Alloy Conductors ASTM B 399

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

||||||

|

AREA

|

|

Stranding and wire diameter

|

Approx. overall diameter

|

Weight

|

Nominal Breaking Load

|

Nom. DC resistance at 20 Deg.

|

||||||

|

Nominal

|

Actual

|

|

|

|

|

|

||||||

|

AWGorMCM

|

(mm2)

|

(mm)

|

(mm)

|

(kg/km)

|

(kN)

|

(ohm/km)

|

||||||

|

6

|

13.3

|

7/1.554

|

4.67

|

37

|

4.22

|

2.5199

|

||||||

|

4

|

21.15

|

1/1.961

|

5.89

|

58

|

6.71

|

1.5824

|

||||||

|

2

|

33.63

|

7/2.474

|

7.42

|

93

|

10.68

|

0.9942

|

||||||

|

1/0

|

53.48

|

7/3.119

|

9.36

|

148

|

16.97

|

0.6256

|

||||||

|

2/0

|

67.42

|

7/3.503

|

10.51

|

186

|

20.52

|

0.4959

|

||||||

|

|

|

|

|

|

|

|

||||||

|

3/0

|

85.03

|

7/3.932

|

11.8

|

234

|

25.86

|

0.3936

|

||||||

|

4/0

|

107.23

|

7/4.417

|

13.26

|

296

|

32.63

|

0.3119

|

||||||

|

250

|

126.66

|

19/2.913

|

14.57

|

349

|

38.93

|

0.2642

|

||||||

|

300

|

152.1

|

19/63.193

|

15.97

|

419

|

46.77

|

0.2199

|

||||||

|

350

|

177.35

|

19/3.447

|

17.24

|

489

|

52.25

|

0.1887

|

||||||

|

|

|

|

|

|

|

|

||||||

|

400

|

202.71

|

19/3.686

|

18.43

|

559

|

59.74

|

0.1650

|

||||||

|

450

|

228

|

19/3.909

|

19.55

|

629

|

67.19

|

0.1467

|

||||||

|

500

|

253.35

|

19/4.120

|

20.6

|

698

|

74.64

|

0.1321

|

||||||

|

550

|

278.6

|

37/3.096

|

21.67

|

768

|

83.80

|

0.1202

|

||||||

|

600

|

303.8

|

37/3.233

|

22.63

|

838

|

91.38

|

0.1102

|

||||||

|

|

|

|

|

|

|

|

||||||

|

650

|

329.25

|

37/3.366

|

23.56

|

908

|

97.94

|

0.1016

|

||||||

|

700

|

354.55

|

37/3.493

|

24.45

|

978

|

102.20

|

0.0944

|

||||||

|

750

|

380.2

|

37/3.617

|

25.32

|

1049

|

109.60

|

0.0880

|

||||||

|

800

|

405.15

|

37/3.734

|

26.14

|

1117

|

116.80

|

0.0826

|

||||||

|

900

|

456.16

|

37/3.962

|

27.73

|

1258

|

131.50

|

0.0733

|

||||||

|

1000

|

506.71

|

37/4.176

|

29.23

|

1399

|

146.10

|

0.0660

|

||||||