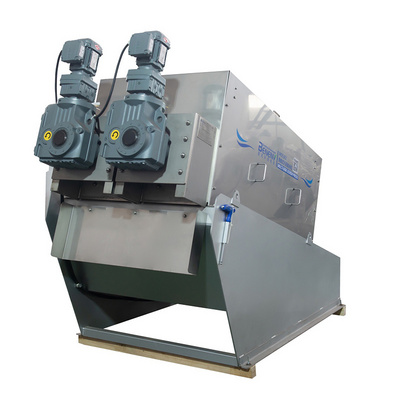

The main body of the dehydration machine is composed of a fixed ring and a movable ring that are layered on top of each other, and the spiral shaft runs through it to form a filtration device. The front section is the concentration section, and the rear section is the dehydration section

The filter gap formed between the fixed ring and the movable ring, as well as the pitch of the spiral shaft, gradually decreases from the concentration part to the dehydration part.

The rotation of the spiral shaft not only drives the sludge to be transported from the concentration section to the dehydration section, but also continuously drives the traveling ring to clean the filter gap and prevent blockage