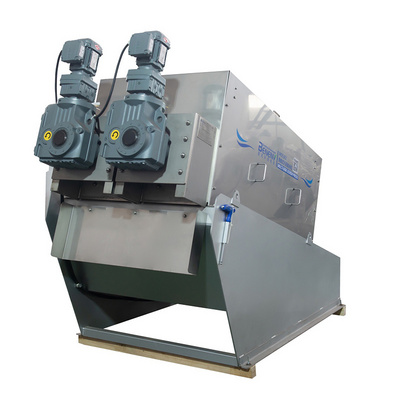

Widely Use

Applicable sludge concentration of 2000mg/L-50000mg/L.

Most especially for the oily sludge.

Fully Automatic Control

Combining with the auto control system, the machine runs very safely and simply and can be programmed according to the requirement

of the users. It can operate automatically for 24 hours, unmanned.

Applicable sludge concentration of 2000mg/L-50000mg/L.

Most especially for the oily sludge.

Fully Automatic Control

Combining with the auto control system, the machine runs very safely and simply and can be programmed according to the requirement

of the users. It can operate automatically for 24 hours, unmanned.