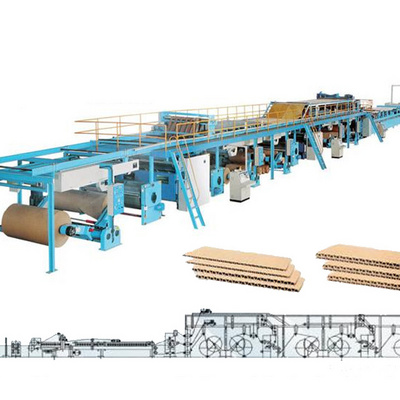

★It adopts double roller symmetrical four arm structure, which can support two rolls of base paper at the same time

★The clamping, loosening, lifting, left-right translation and other operations of the base paper are hydraulically driven

★Imported multi-point braking device and expanded paper clamping head are adopted to reduce the waste of base paper

★The clamping, loosening, lifting, left-right translation and other operations of the base paper are hydraulically driven

★Imported multi-point braking device and expanded paper clamping head are adopted to reduce the waste of base paper

2. Paper loading trolley and guide rail