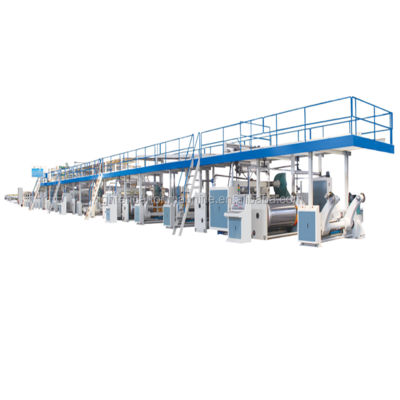

Spindle ¢ 240mm, hyperbolic heavy rocker, expand chuck , multi-point brake, hydraulic drive lifting, panning left and right on the

middle.Guide rail length 6000mm,use of plate welding.

Pre-heater