NaN / 0

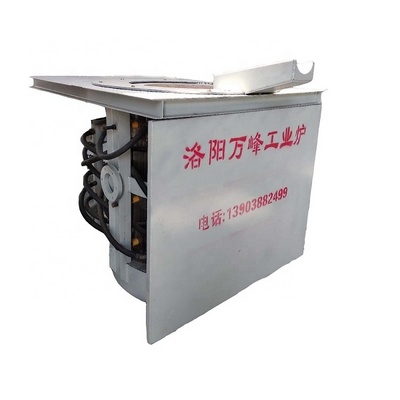

1 Ton Induction Metal Melting Machine 1000 KG Aluminium Can Smelting Furnace for Sale

Get Latest Price

US$ 22222

≥1 Pieces

Quick Details

Place of Origin:

China

Core Components:

SCR

Brand Name:

WANFENG

Voltage:

380V

Product Details

HOW TO MAKE ALUMINUM INGOT FROM RECYCLED CAN

It is to put the recovered cans into the pot and melt them into aluminum liquid, then scoop them out with a spoon and pour them into the mold to form ingots. It should be noted that the cans are light and thin materials commonly and are easy to burn off. The best way is to melt some aluminum liquid in the furnace chamber, and then cast in ingot mold.

1. Smelting directly into coarse aluminum ingot: mixing the waste cans in the smelting furnace to obtain a kind of metal ingot similar to cooked aluminum;

2. For smelting some brands of alloy: some standard enterprises need to add some pure aluminum ingot to adjust the composition by melting and casting aluminum alloy, but the magnesium content of the alloy is often increased. This method is more practical for the production of aluminium alloys with high magnesium content;

3. Mix with other waste aluminum to produce miscellaneous aluminum ingot;

4. Aluminum granule for making steel hot liquid oxygen free.

Aluminum granule is mainly used for diffusion deoxidation. The aluminum block has small specific gravity, light weight, and low melting point. It is generally used for surface deoxidation. On the market, the general aluminum block is divided into trapezoid, conical, etc. the final deoxidation effect is directly related to the purity of aluminum.

5. Production of aluminum powder: the waste cans are taken paint off in rotary kiln, and then processed to produce low-grade aluminum powder.

When making aluminum ingot with can, we must master the correct operation method, so as to get better processing effect. Please contact Luoyang Wanfeng for more details

It is to put the recovered cans into the pot and melt them into aluminum liquid, then scoop them out with a spoon and pour them into the mold to form ingots. It should be noted that the cans are light and thin materials commonly and are easy to burn off. The best way is to melt some aluminum liquid in the furnace chamber, and then cast in ingot mold.

1. Smelting directly into coarse aluminum ingot: mixing the waste cans in the smelting furnace to obtain a kind of metal ingot similar to cooked aluminum;

2. For smelting some brands of alloy: some standard enterprises need to add some pure aluminum ingot to adjust the composition by melting and casting aluminum alloy, but the magnesium content of the alloy is often increased. This method is more practical for the production of aluminium alloys with high magnesium content;

3. Mix with other waste aluminum to produce miscellaneous aluminum ingot;

4. Aluminum granule for making steel hot liquid oxygen free.

Aluminum granule is mainly used for diffusion deoxidation. The aluminum block has small specific gravity, light weight, and low melting point. It is generally used for surface deoxidation. On the market, the general aluminum block is divided into trapezoid, conical, etc. the final deoxidation effect is directly related to the purity of aluminum.

5. Production of aluminum powder: the waste cans are taken paint off in rotary kiln, and then processed to produce low-grade aluminum powder.

When making aluminum ingot with can, we must master the correct operation method, so as to get better processing effect. Please contact Luoyang Wanfeng for more details

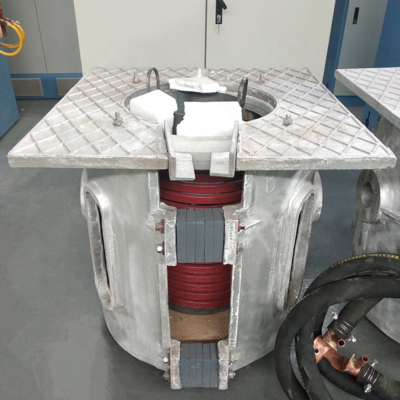

Intermediate frequency aluminum melting furnace is mainly used for smelting and raising temperature of aluminum and aluminum alloy, especially for melting places with large amount of return materials and single furnace intermittent operation, such as aluminum profile, aluminum products, alloy plate and waste aluminum recovery.

Whole set of smelting furnace equipment includes medium frequency power supply cabinet, compensation capacitor, furnace body (two), water cooling cable and reducer. The furnace body is composed of furnace shell, induction ring and tilting furnace reducer. The furnace shell is made of non-magnetic materials. The induction coil is a spiral cylinder made of rectangular hollow tubes. Cooling water is passed through the tube during melting. The copper bar from the coil is connected with the water-cooled cable, and the tilting of the furnace body is directly rotated by the furnace tilting reducer. Tilting furnace reducer is a two-stage turbine with variable speed, good self-locking performance, stable and reliable rotation. In case of emergency power failure, the furnace can be manually tipped to avoid danger.

|

1. Small size, light weight, high efficiency and low power consumption;

|

|

|

|

|

||||

|

2. Low ambient temperature, less smoke and dust, good working environment;

|

|

|

|

|

||||

|

3. The operation process is simple and the smelting operation is reliable;

|

|

|

|

|

||||

|

4. Uniform heating temperature to less burning loss and even metal composition;

|

|

|

|

|

||||

|

5. The casting quality is good, the melting temperature is fast, the furnace

temperature is easy to control and the production efficiency is high; |

|

|

|

|

||||

|

6. It has high utilization rate and easy to change varieties.

|

|

|

|

|

||||

FAQ

1. Our workers are not professional and have no idea about how to use induction furnace. What can you help for us?

An:You will enjoy WANFENG overseas turn-key project service, inclusive free training 2 operators.Your workers will learn about how to operate and how to maintenance WANFENG induction furnace in daily.

2. What's your power supply? Using electricity or gas or coke coal?

An: we can offer aluminum melting furnace with electricity power or gas or coke coal. Induction melting furnace use electricity.

3. How about your package?

An: we can offer plywood case, tray, frame, wire fixing.

Fragile part will be wrapped with carton plate and pearl cotton sheet and be glued with warning mark of breakable.

4. How about color?

An: customized and note us RAL ID numeral and we will confirm it with workshop.

5. Can you offer OEM service?

An: Absolutely yes, after getting your brand mark authorization we love to offer OEM service for you.

6. Can you ODM?

An: Yes, send us your description and picture or video, then we design fit one for your case.

7. How long is delivery time?

An: 7-14 days for available in stock; 15-25 days for customized. Delivery time is also determined by quantity of ordered equipment. Final delivery time is up to sales contract.

Contact Us

contact person: LISALEE

whataspp: +8618039411976

email: info@wanf-furnace.com

Factory visiting:

time: 9:00~17:00

appointment:+8618037968986

receipt person: Damon Zhang

Hot Searches