NaN / 0

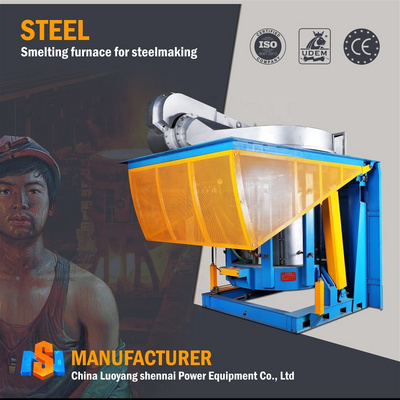

1700 degree metal smelting furnace 1800c induction melting furnace 2 tonne induction furnace

Get Latest Price

US$ 3000

≥1 Sets

Quick Details

Place of Origin:

Henan, China

Brand Name:

ShenNai

Voltage:

660*2V

Dimension(L*W*H):

1900mm*1850mm*1900mm

Product Details

The medium frequency smelting furnace mainly used for melting and refining all kinds of scrap

metal, iron, stainless steel, copper, aluminum.

This furnace can smelting the scrap iron, like scrap auto parts, scrap steel bars, scrap screws, iron leftover materials etc.

Product Features:

- Various capacity 0.1T -20T, fast melting speed, 40-60 minutes /pot.

- Have self-test function, real-time supervise.

- Have leaking alarm device, PLC control, easy to operate.

- The control cabinet is standard of the automobile line, easy to maintain

- The water way uses carbon-free hose , water separetors and clips use 304 stainless steel

- Can meet 24 hours continuous work.

- High efficiency , low cost , easy to maintain, energy saving ,safe and stability.

The melting furnace mainly composed of power control cabinet and melting furnace body.

- The equipment can meet 24 hours of continuous work.

- It have self-test function and leaking alarm device.

- Real-time detection of water temperature, water pressure, over-current, over-voltage, lack phase information.

|

Induction Melting Furnace: It has the bottom of the oxygen blowing, reducing carbon, slagging function. Cyclone type smoke hood has excellent dust absorption , thermal insulation effect and take up a small space. Long service life.

|

|

|

Power Supply:

The utility model has the advantages of obvious energy saving effect and 20% saving compared with common equipment.

|

|

|

Closed type cooling tower: Heat exchanger:The materials of coil group is high quality of T2 depickling copper tube or stainless steel pipe .Set water tank and the tower body is made of aluminum zinc steel plate plate and the service life is over 15years. |

|

|

Hydraulic pressure station:

Including hydraulic pump station and tilting furnace operating table.

|

|

|

Capacitor Bank :

The double-layer mica insulation technology is used for the insulation treatment of the capacitor.

|

Hot Searches