NaN / 0

wood burning stove/wood pellet steam boiler

Get Latest Price

US$ 20000

≥1 Sets

US$ 15000

≥5 Sets

Quick Details

Place of Origin:

Hebei, China

Brand Name:

WANDA

Dimension(L*W*H):

Depends on boiler capacity

Weight:

2000

Product Details

Product Description

Automatic fuel (gas) steam boiler using a horizontal wet back combustion full, efficient threaded pipe with sound insulation outsourcing design, thermal efficiency up to 85%, the product design, rational structure, good process performance, so that the products with extraordinary excellent quality.

With full waveform furnace, with good thermal stretchable; full pull side butt welding technology, reducing the furnace temperature stress; tube and tube plate connected by welding form after the first expansion, eliminate corrosion problems, extend the life of the boiler; threaded pipe heat exchanger, to improve the heat transfer coefficient of the boiler.

Features

1. Adopted popular inernal combustion three-return full wet back boiler, boiler radiation heating surface is whole corrugated furnace increase the heated area and satisfied self expansion of the hot furnace.

2. Adopted screw smoke tube, enforce the heating efficiency.

3, Rear- view device design, easy to observing the working status.

4. Auto protection when Over temperature, Overpressure, Water leaking, Water shortage, Flameout etc. , a gurantee of safe running .

5. 3 style exterior decoration can be choosed : Lathe work , mirror finished stainless steel, Matt stainless steel .

6. Imported Burner : Italy Baltur.

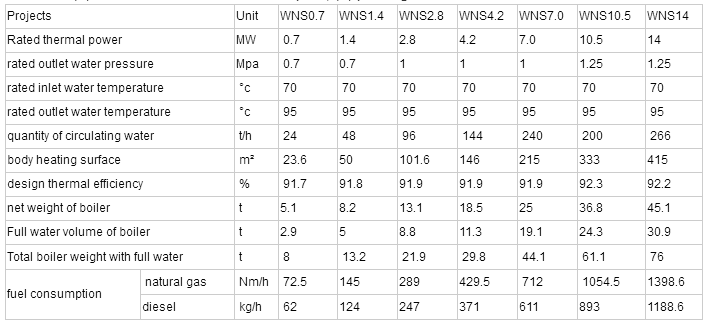

Technical parameter

Packing & Delivery

Our Service

Our Company

LIAOYANG WANDA MACHINERY CO.,LTD is specialized in design, development, manufacture and sale, chemical and packaging machinery.Our products include filter, centrifuge, mixer,granulator, dryer, packing machine, teabag packing machine, etc.

Our company follows strict quality controls and various systematic procedures. We take utmost care of quality at every stage of the manufacturing process.

Our research and development wing is our asset that develops and incorporates innovative ideas and products. Our Team is full of experienced and qualified professionals, who have sound knowledge about the quality of our machinery. Our products are far sold to Europe, U.S.A., and the southeast Asia. They are well received by customers both at home and abroad.

Related Products