NaN / 0

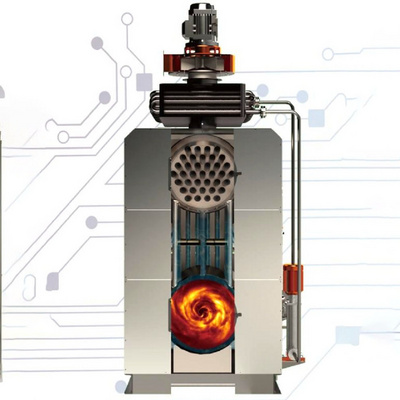

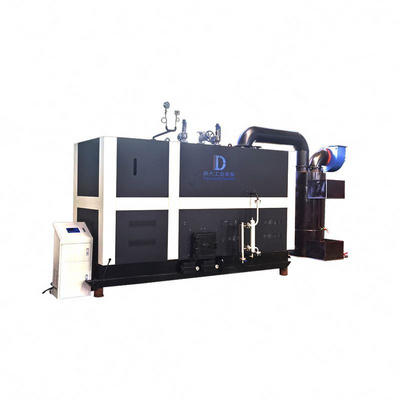

Cheap Cost Wood Fired Pellet Burning Stove Steam Generator Boiler For Sale

Get Latest Price

US$ 6500

≥1 Pieces

Quick Details

Core Components:

Water gall, Heating device

Steam Production:

0.5t/h~1.0t/h

Place of Origin:

Shandong, China

Brand Name:

Dingda

Product Details

Product Display

|

Product Name

|

Firewood steam generator

|

|

Measured maximum evaporation

|

1000kg/h

|

|

Fixed work stress

|

1.0MPA

|

|

Fuel consumption

|

150kg

|

|

Boiler thermal efficiency

|

98%

|

|

Water capacity

|

29L

|

|

Silo capacity

|

400kg

|

|

Blower

|

1500W

|

|

Induced draft fan

|

3000W

|

|

Multi-stage water pump

|

2200W

|

|

Feed motor

|

200W

|

|

Steam outlet pipe diameter DN

|

50mm

|

|

Safety valve diameter DN

|

40 (flange type) mm2

|

|

Chimney diameter

|

159mm

|

|

Product Size

|

4700*1800*2600mm

|

|

Water dust removal size

|

1500*1200*2600mm

|

|

Boiler weight

|

7500kg

|

Details Images

1. The fuel contains a large amount of hydrogen, which produces a large amount of water vapor when burned. After 1NM3 natural gas is burned, it can produce 1.55KG of water vapor, which has considerable latent heat of vaporization, about 3700KJ, which accounts for about 10% of the low calorific value of natural gas. When the exhaust gas temperature is high, the water vapor cannot be condensed to release heat, and is discharged with the flue gas, and the heat is wasted. At the same time, the high-temperature flue gas also takes away a large amount of sensible heat, which together causes a larger exhaust loss.

2. The flue gas condensation waste heat recovery device uses lower temperature water or air to cool the flue gas to reduce the flue gas temperature. Close to the heat exchange surface area, the water vapor in the flue gas condenses, and at the same time realizes the sensible heat release and water vapor of the flue gas The latent heat of condensation is released, and the water or air in the heat exchanger absorbs heat to be heated, which realizes heat energy recovery and improves the thermal efficiency of the boiler.

3. Improved boiler thermal efficiency: 1NM3 natural gas combustion produces theoretical flue gas volume of about 10.3 NM3 (about 12.5KG). Taking the excess air coefficient of 1.3 as an example, 14 NM3 of flue gas (about 16.6KG) is produced. When the temperature of the flue gas is reduced from 200°C to 70°C, the physical sensible heat is about 1600KJ, the water vapor condensation rate is 50%, and the latent heat of vaporization is about 1850 KJ. The total heat release is 3450 KJ, which is about 10% of the low calorific value of natural gas. If 80% of the flue gas is taken into the thermal energy recovery device, the thermal energy utilization rate can be increased by more than 8%, and the natural gas fuel can be saved by nearly 10%.

4. The heat pipe fin type condensing heat exchanger is used, which effectively reduces the exhaust gas temperature.

5. Safety: B-level manufacturing qualification, drawings are reviewed by the provincial special inspection institute with seals, and each product is

The provincial special inspection institute passes the inspection and leaves the factory to ensure safety.

6. High efficiency: equipped with special high-efficiency energy-saving devices, advanced water-saving generators

The energy device enters the furnace to make full use of the waste heat of the flue gas, and the gas production speed is greatly increased.

7. Stability: The factory is standardized

Mass production, superb technology, stable product operation and low failure rate.

8. Simple: automatic control, with flame detection, pressure detection, overpressure protection, water shortage protection, overheating protection, automatic alarm, no need for special personnel on duty.

9. The factory installation of the whole product only needs to be connected to the power supply, steam pipe, water inlet pipe, sewage pipe and chimney, which saves installation costs and a large amount of installation materials.

10. Sophisticated configuration: equipped with flat-plate water level gauge, imported pressure controller, high temperature and high pressure water pump and high-quality burner, which can greatly reduce the failure rate of products.

11. Environmental protection: equipped with high-quality burner, full combustion, low flue gas emissions of particulate matter and nitrogen itch, in line with relevant national emission standards.

12. Substitution: This product is a one-piece factory, small in size, steam boilers less than 10 tons can be replaced by this steam generator in a modular combination.

13. Steam can be produced in 90-120 seconds, and pure steam can be continuously output at high pressure! The steam has a built-in insulation layer, and the thermal efficiency can reach more than 98%, saving fuel

14. Equipped with dual safety valves, dual water level gauges inside and outside, dual temperature control detection, multiple protections, and more safety.

Main Products