NaN / 0

LONKIA commercial vegetable apple mango cassava slicing washing drying machine dried fruit chips production line

Get Latest Price

US$ 25800

≥1 Sets

Quick Details

Machinery Capacity:

100-1500kg/h

Brand Name:

LONKIA

Year:

2022

Dimension(L*W*H):

customized

Product Details

Product Description

Advantages of air drying equipment

Good drying effect: it can realize the open and closed circulating drying of atmospheric pressure, medium and low temperature air, and the quality of materials after drying is high Safety and environmental

protection: during the drying process, the machine has no waste water, waste gas and waste residue, so as to protect the

environment Easy installation: integrated design, easy installation and maintenance

protection: during the drying process, the machine has no waste water, waste gas and waste residue, so as to protect the

environment Easy installation: integrated design, easy installation and maintenance

Full automation: convenient temperature and humidity regulation, and the drying process can be automated

Energy saving and high efficiency: low operation cost.

Usually There is three working mode

only

Drying

Drying + dehumidify

Cooling

Drying: temperature can rise fast, but dryer cannot discharge moisture air

Drying + dehumidify: chamber temperature rise and discharge moisture air

Cooling: temperature can down to 10c(minimum)

Sometimes, if the dryer cannot control the temperature accurately, please choose Temper + humidity

Drying machine FAQ

1.high pressure protection

A.hot air circulating fans does not working

a1. AC contactor use for hot air circulating fans overloading protection(please check power source whether lack phase/connecting port or voltage not stable)

a2. part of hot air circulating fan not working(check whether the fans have many ON/OFF switch or some fans was burned)

a3. Fan was damaged (replace new fan or uninstall damaged fans)

B.Too much more products on trays or too much more trays on trolleys lead to block hot air (hot air cannot circulating in drying chamber or too slow wind speed, usually two tray’s distance at 8-10cm is reasonable).

C.electronic expansion valve throttle opening too small; or jammed.

c1. Controller adjust electronic expansion valve’s opening to small automatically(temperature sensor not accurate—change installation place, exchange 1# and 2# sensor’s position)

c2. electronic expansion valve does not working(turn valve body)

D.chamber’s temperature too high(set lower temperature)

E.refrigerant is not high temperature type, re-fill gas.

2. low pressure protection

A. leak gas(check leak point, repair)

B. weather too cold(expand check time for low pressure protection, or charge low temperature gas, e.g. R22/R417A)

C. electronic expansion valve opening too small(adjust bigger)

3. exhaust temperature too high protection

A. leak gas(check leak point, repair),

B. electronic expansion valve does not working(turn valve body).

4. temperature sensor error(replace new one)

5. discharge moisture too slow or does not discharge moisture

Drying

Drying + dehumidify

Cooling

Drying: temperature can rise fast, but dryer cannot discharge moisture air

Drying + dehumidify: chamber temperature rise and discharge moisture air

Cooling: temperature can down to 10c(minimum)

Sometimes, if the dryer cannot control the temperature accurately, please choose Temper + humidity

Drying machine FAQ

1.high pressure protection

A.hot air circulating fans does not working

a1. AC contactor use for hot air circulating fans overloading protection(please check power source whether lack phase/connecting port or voltage not stable)

a2. part of hot air circulating fan not working(check whether the fans have many ON/OFF switch or some fans was burned)

a3. Fan was damaged (replace new fan or uninstall damaged fans)

B.Too much more products on trays or too much more trays on trolleys lead to block hot air (hot air cannot circulating in drying chamber or too slow wind speed, usually two tray’s distance at 8-10cm is reasonable).

C.electronic expansion valve throttle opening too small; or jammed.

c1. Controller adjust electronic expansion valve’s opening to small automatically(temperature sensor not accurate—change installation place, exchange 1# and 2# sensor’s position)

c2. electronic expansion valve does not working(turn valve body)

D.chamber’s temperature too high(set lower temperature)

E.refrigerant is not high temperature type, re-fill gas.

2. low pressure protection

A. leak gas(check leak point, repair)

B. weather too cold(expand check time for low pressure protection, or charge low temperature gas, e.g. R22/R417A)

C. electronic expansion valve opening too small(adjust bigger)

3. exhaust temperature too high protection

A. leak gas(check leak point, repair),

B. electronic expansion valve does not working(turn valve body).

4. temperature sensor error(replace new one)

5. discharge moisture too slow or does not discharge moisture

A. dehumidify fan was damaged,

B. controller go wrong,

C. dehumidify fan power

Equipment characteristics :

Energy conservation and environmental protection: 75% energy saving and no pollution Omnipotent and

efficient: It can be heated and dehumidified at constant temperature, saving 40% of time.It is suitable for various use

environments and seasons and is used all year round Best choice of scheme Convenient and easy to operate: One click start, PIC system control and segmented setting of temperature and humidity make it easy to learn and operate after simple training.

Energy conservation and environmental protection: 75% energy saving and no pollution Omnipotent and

efficient: It can be heated and dehumidified at constant temperature, saving 40% of time.It is suitable for various use

environments and seasons and is used all year round Best choice of scheme Convenient and easy to operate: One click start, PIC system control and segmented setting of temperature and humidity make it easy to learn and operate after simple training.

|

Model

|

Unit

|

LK-300H

|

LK-600H

|

LK-1200H

|

|

Power input

|

KW

|

5.5

|

9.5

|

19.4

|

|

Heating capacity

|

KW

|

10.5

|

21.0

|

42.0

|

|

Cooling capacity

|

KW

|

7.8

|

18.0

|

32.0

|

|

Dehumidity

|

L/H

|

12.0

|

25.0

|

50.0

|

|

Max temperature

|

℃

|

≤75

|

≤75

|

≤75

|

|

Working condition

|

℃

|

0-43

|

0-43

|

0-43

|

|

Max exhause pressure

|

M(P)a

|

30

|

30

|

30

|

|

Power consumption/H

|

KWH

|

4.8

|

8.5

|

15.0

|

|

Electric heater

|

KW

|

3.0

|

6.0

|

12.0

|

|

Demsnssion of dryer

|

MM

|

3160*2070*2200

|

5700*2170*2200

|

5810*3230*2200

|

Drying effect:

Product Photography

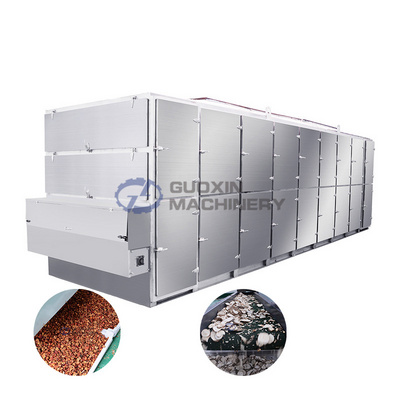

Display of various drying equipment

01.

Drying production line

02.

Multi layer dryer

03.

Air energy drying room

Application

The main purpose of an oven is

mainly used for mushrooms, grapes, gardenia fruit, Zelan, orange peel, sweet potato, kelp, fish, sea cucumber, prune, ginger, rose fruit, banana, apple, etc.

Drying is the process of manually controlling the evaporation of food moisture. There are also some foods that can have different flavors after drying. For example, mushrooms, Meigan cai.

Hot Searches