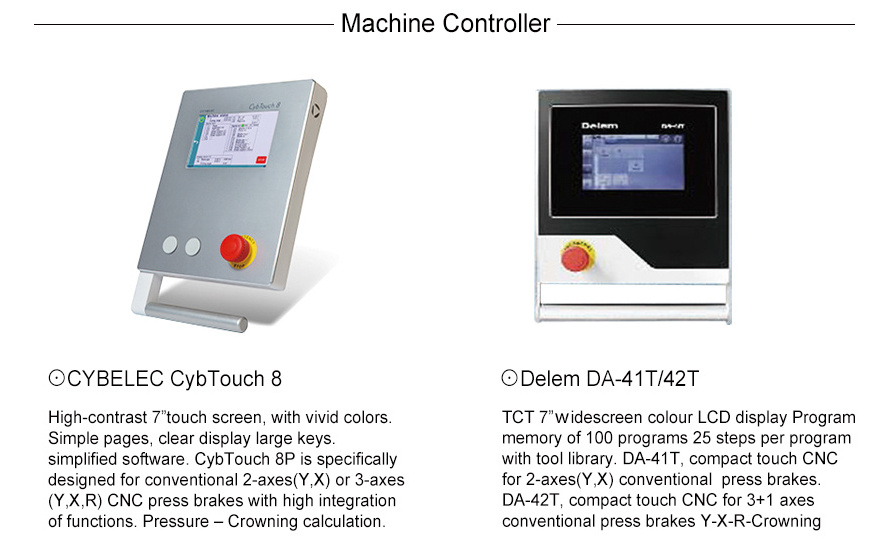

CNC crowning ensures a constant

bend angle across the full length

of

the machine.

This is achieved by preloading the machine, to offset any possible deflection under load or

compensate for any tool wear.