NaN / 0

Low cost Semi Automatic Vacuum Forming Thermoforming Machine manual for plastic tray

Get Latest Price

US$ 4500

≥1 Pieces

US$ 4000

≥2 Pieces

Quick Details

Model NO:

Hx-2224

Transport Package:

1. Wooden box or wooden frame, box: 30 USD/CBM, wooden frame: 15 USD/CBM;

Specification:

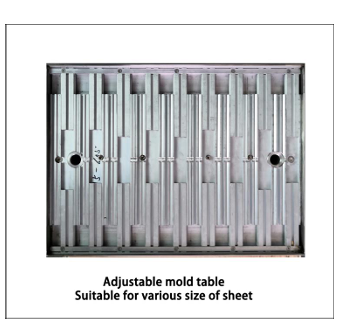

L1800*w1480*H1800

Trademark:

Huaxiang

Product Details

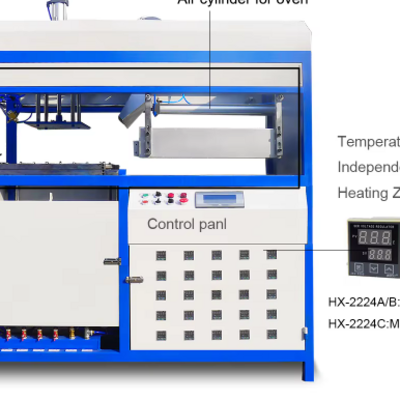

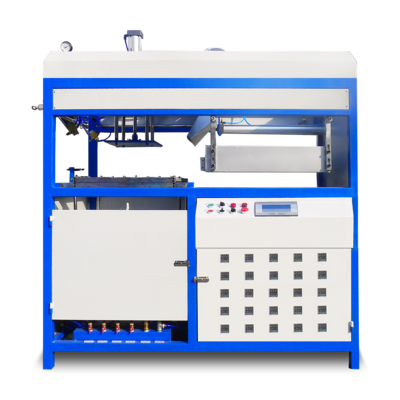

HX-2224 Series Semi-automatic Vacuum Forming/Thermoforming Machine

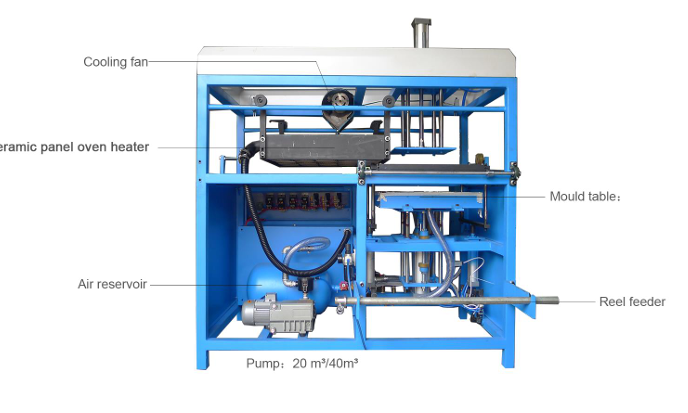

PLC touch screen control, HX-2224A a user friendly machine with the power and capability to form demanding shapes and materials.Rapid, energy efficient ceramic heaters with variable standby ,pneumatic table and clamping provides effortless operation, whilst the vacuum tank system fitted as standard facilitates ultra-fast response for demanding applications and fast cycle times.

Application

Thermoforming differs from injection molding, blow molding, rotational molding and other forms of processing plastics. Thin-gauge thermoforming is primarily the manufacture of disposable cups, containers, lids, trays, blisters, clamshells, and other products for the food, medical, and general retail industries.

Types of moldsWood Patterns;

Cast aluminum Molds;

Machined aluminum Molds;

Composite Molds;

Function:

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine PET Bottle Making Machine is suitable for

producing PET plastic containers and bottles in all shapes

Features:

1) 25pcs ceramic infrared heating boards which can be controlled separately, suitable for different size or different thickness material.

2) 25pcs Solid state voltage regulators, control heating boards simple and visualized.

3) Large-scale cooling fan which can cool the products quickly.

4) Cooling system which suitable for thick material. (optional)

5) Manual and Semi-auto style.

Hot Searches