NaN / 0

Plastic Thermoforming Vacuum Forming/Molding fruit egg carton tray making machine

Get Latest Price

US$ 26800

≥1 Pieces

US$ 26500

≥2 Pieces

US$ 26000

≥3 Pieces

Quick Details

Model NO:

Hx-18

Transport Package:

1. Wooden box or wooden frame, box: 30 USD/CBM, wooden frame: 15 USD/CBM;

Specification:

L1800*w1480*H1800

Trademark:

Huaxiang

Product Details

Plastic Thermoforming Vacuum Forming/Molding fruit egg carton tray making machine

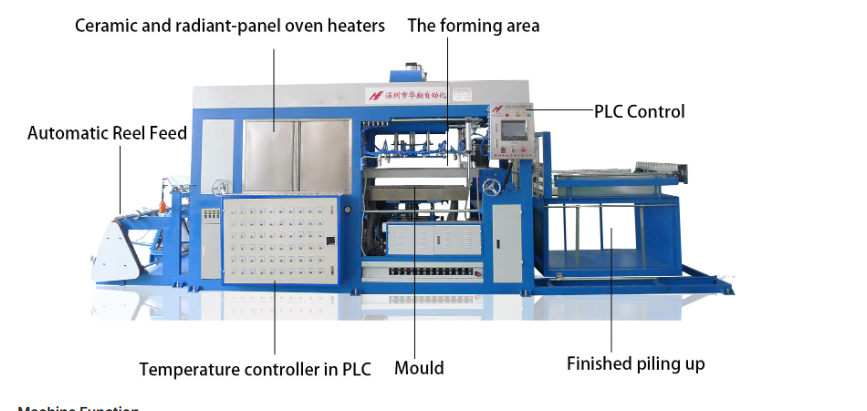

HX-18 series is user friendly machine with the power and capability to form demanding shapes and materials, Price-performance ratio for automatic production class machines. Combines the material feeding, heating, drawing, forming, and stacking into one process. Efficient heat management, ease of use, big forming size and accessible price are instrumental to the internationally successful by many companies.

This machine has high capacity and advanced technology for large outputs with low moulds cost.

Application

Thermoforming differs from injection molding, blow molding, rotational molding and other forms of processing plastics. Thin-gauge thermoforming is primarily the manufacture of disposable cups, containers, lids, trays, blisters, clamshells, and other products for the food, medical, and general retail industries.

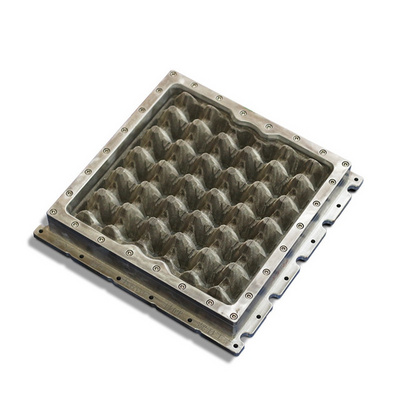

Types of Molds Wood Patterns

Cast aluminum Molds; Machined aluminum Molds; Composite Molds;

Function:

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine PET Bottle Making Machine is suitable for

producing PET plastic containers and bottles in all shapes

Features:

1. In the digital temperature controller, temperature setting is convenient, high precision of temperature control;

2. Ceramic and radiant-panel oven heaters generally provide more precise and thorough sheet heating Allow for zoning of ovens into areas of adjustable heat;

3. rather than air cylinders which have traditionally been the industry standard, giving more precise control over closing and opening speeds and timing of the tooling;

4. The ability to place formed sheet into an inline trim station for more precise trim registration has been hugely improved due to the common use of electric motors for chain indexing versus air cylinders, gear racks, and clutches on older machines;

5.Heavy-duty industrial design

6.Plug/grid assist adjustable from touch screen

7.High-powered cooling blower and water-cooled mold plate to reduce process time

8.Electrical cabinet and installation to CE standard

Hot Searches