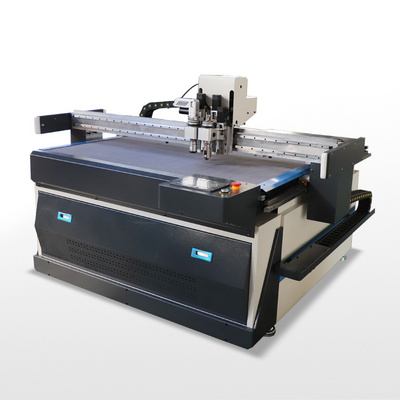

1. Instead of the traditional needle and thread technology, the equipment adopts PLC to centrally control the entire operating

system, and the entire processing action is automated, saving labor and improving efficiency.

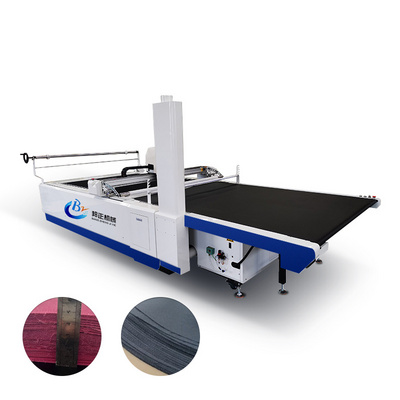

2. The cradle-type unwinding rack adopts dual-roller split-flow conveying, and the transmission shaft straightens the fabric,

and the baffles on both sides of the fabric of different lengths can be adjusted at will.

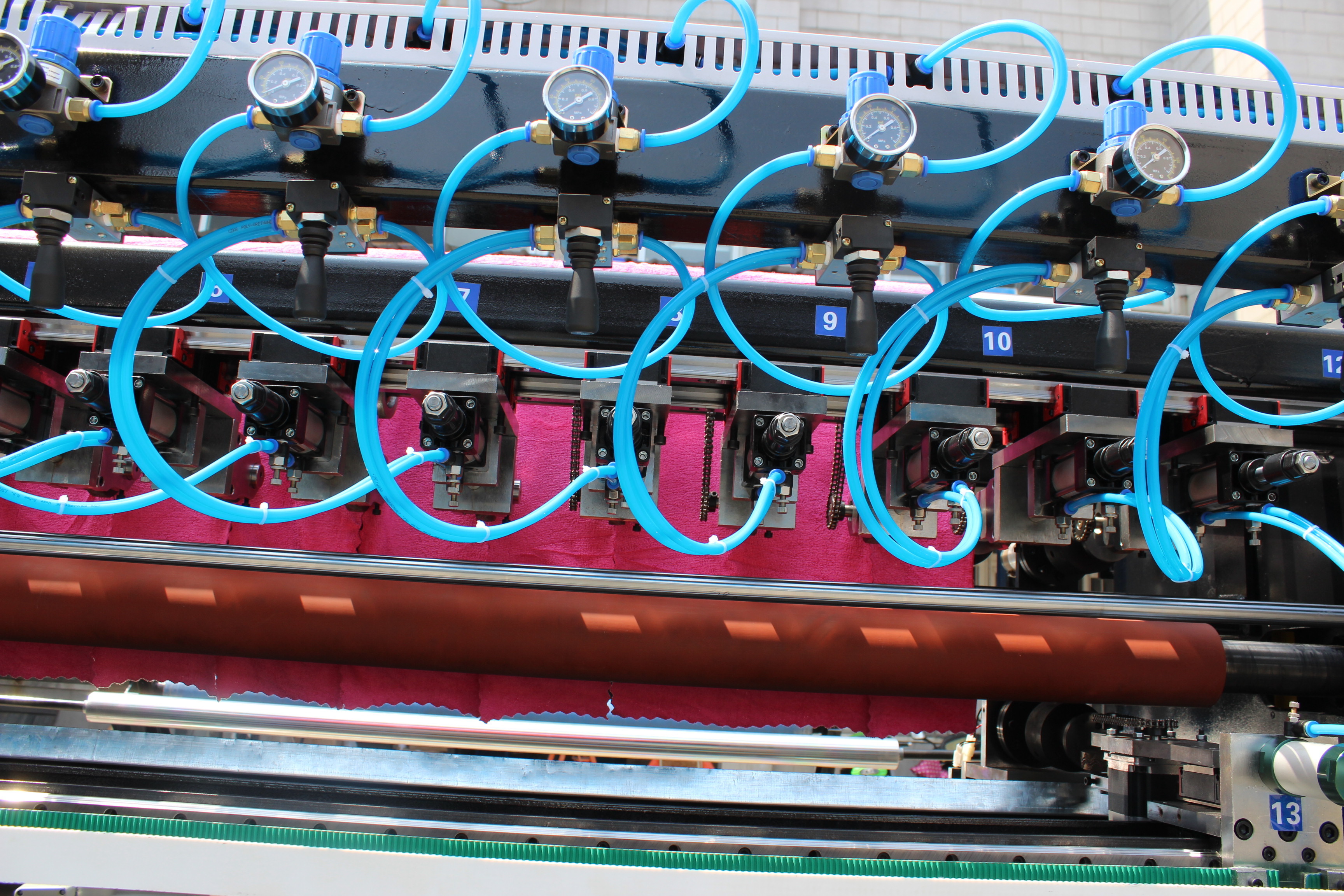

3. Automatic deviation correction control system, the uniform error of the feeding process is small, which improves the

smoothness and cleanliness of the incision, and is more energy-saving.

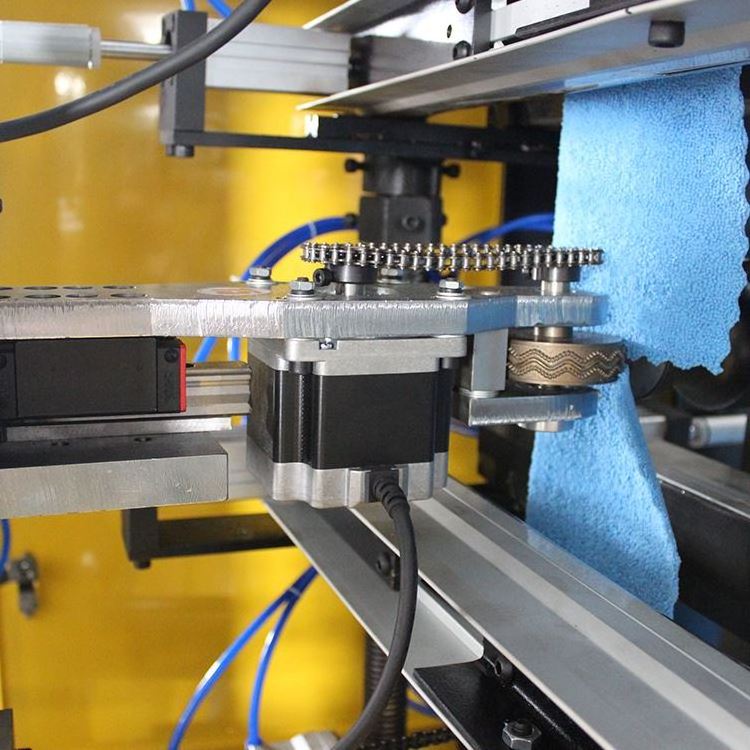

4. Guide rail slide block vertical cutting (convenient and stable to adjust the vertical cutting size)/cross cutting (even and

stable and reliable in high-speed operation), the cut fabric has no burrs, neat, no deviation, and the width is adjustable.

5 The mechanical structure is strong and the stability of high-speed operation is high, which effectively improves the

durability and service life of the machine.

system, and the entire processing action is automated, saving labor and improving efficiency.

2. The cradle-type unwinding rack adopts dual-roller split-flow conveying, and the transmission shaft straightens the fabric,

and the baffles on both sides of the fabric of different lengths can be adjusted at will.

3. Automatic deviation correction control system, the uniform error of the feeding process is small, which improves the

smoothness and cleanliness of the incision, and is more energy-saving.

4. Guide rail slide block vertical cutting (convenient and stable to adjust the vertical cutting size)/cross cutting (even and

stable and reliable in high-speed operation), the cut fabric has no burrs, neat, no deviation, and the width is adjustable.

5 The mechanical structure is strong and the stability of high-speed operation is high, which effectively improves the

durability and service life of the machine.