NaN / 0

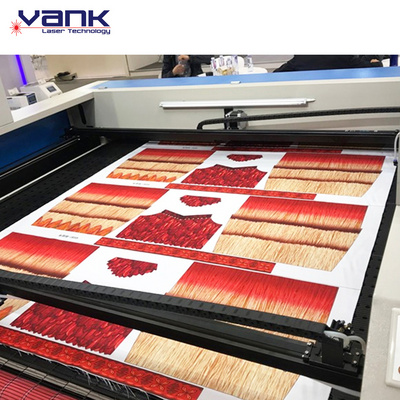

Laser Fabric Cutting Machine Automatic Printed Pattern Leather Textile Fabric Laser Cutting Machine

Get Latest Price

US$ 7880

≥1 Sets

US$ 7850

≥3 Sets

US$ 7800

≥6 Sets

Quick Details

Laser Type:

CO2

Cutting Speed:

0-6000mm/s

Cooling Mode:

WATER COOLING

Control System Brand:

RuiDa

Product Details

Products Description

Dye sublimation printing onto large format textiles is now very popular for producing sportswear, flags and banners, due to the printers becoming faster and more cost effective. The only issue remaining is how to cut out the printed parts. Manually cutting is too slow, inconsistent and labour intensive.

Big vision laser cutting machine made by Anhui Vanklaser, automates the process of cutting out dye sublimation printed pieces of fabric or textile both quickly and accurately, automatically compensating for any distortions or stretches that occur in unstable or stretchy textiles - exactly the type of fabrics that are used in sportswear, for example.

TRADITIONAL MANUAL CUTTING METHOD

ONE MACHINE =

FOUR WORKERS

LESS THAN

SIX MONTHS'

ROI

KEY FEATURES OF VISION LASER CUTTING

Fabric Laser Cutting Machine characteristics

1)This laser cutting machine delivers fast and extremely accurate processing thanks to its high-quality components.Very dependable and maintenance free.

2)This laser machine comes with conveyor system. The machine feeds the material automatically in a continuous cycle in synchronism with the conveyor bed eliminating downtime completely to achieve the maximum productivity possible.

3)The vacuum conveyor worktable has the function of negative pressure adsorption to ensure the flatness of the fabric during laser cutting.

4)Automatic feeder with deviation correction function (optional) to ensure accurate feeding.

5)The unique manual and automatic interactive nesting software function can improve the fabric utilization to the extreme.

6)Along with the exhaust system, the laser head and the exhaust system synchronize; good exhaust effect, to ensure that dust dose not pollute the materials.

7)It is possible to complete entire format cutting of the extra-long layout with a single layout length that exceeds the cut format.

8)Along with the exhaust system, the laser head and the exhaust system synchronize; good exhaust effect, to ensure that dust dose not pollute the materials.

1)This laser cutting machine delivers fast and extremely accurate processing thanks to its high-quality components.Very dependable and maintenance free.

2)This laser machine comes with conveyor system. The machine feeds the material automatically in a continuous cycle in synchronism with the conveyor bed eliminating downtime completely to achieve the maximum productivity possible.

3)The vacuum conveyor worktable has the function of negative pressure adsorption to ensure the flatness of the fabric during laser cutting.

4)Automatic feeder with deviation correction function (optional) to ensure accurate feeding.

5)The unique manual and automatic interactive nesting software function can improve the fabric utilization to the extreme.

6)Along with the exhaust system, the laser head and the exhaust system synchronize; good exhaust effect, to ensure that dust dose not pollute the materials.

7)It is possible to complete entire format cutting of the extra-long layout with a single layout length that exceeds the cut format.

8)Along with the exhaust system, the laser head and the exhaust system synchronize; good exhaust effect, to ensure that dust dose not pollute the materials.

• It is a feeding unit which runs synchronous with the laser cutter. the feeder will transfer the roll materials to the cutting

table after you put the rolls on the feeder. You can set the different feeding speeds according to the main machine speed. The

feeder has the sensor to ensure accurate positioning of the material.

table after you put the rolls on the feeder. You can set the different feeding speeds according to the main machine speed. The

feeder has the sensor to ensure accurate positioning of the material.

• Independent dual heads

The independent dual heads can cut different designs at the same time. It increases the cutting efficiency and production

flexibility at the largest degree.

The independent dual heads can cut different designs at the same time. It increases the cutting efficiency and production

flexibility at the largest degree.

Product parameter

|

MODEL

|

VANKPRO 1810/1812

|

|

|

|

|||

|

Laser Tube Power

|

80W/100W/120W/150W /300w

|

|

|

|

|||

|

Working Area

|

1800x1000mm/1800x1200

|

|

|

|

|||

|

Laser Tube

|

Sealed Glass Co2 Laser Tube,10.6um

|

|

|

|

|||

|

Cooling Type

|

Water Cooling

|

|

|

|

|||

|

Engraving Speed

|

0-60000mm/min

|

|

|

|

|||

|

Cutting Speed

|

0-40000mm/min

|

|

|

|

|||

|

Laser Output Control

|

0-100% set by software

|

|

|

|

|||

|

Min.Engraving Size

|

Chinese:2*2mm,English Letter:1*1mm

|

|

|

|

|||

|

Highest Scanning Precision

|

4000DPI

|

|

|

|

|||

|

Locating Accuracy

|

±0.01mm

|

|

|

|

|||

|

Control Software

|

Touch Panel Control

|

|

|

|

|||

|

Graphic Format Supported

|

DST/PLT/BMP/DXF/DWG/AI/HPGL...

|

|

|

|

|||

|

Compatible Software

|

CORELDRAW/PHOTOSHOP/AUTOCAD/TAJIMA....

|

|

|

|

|||

|

Drive System

|

High-precision 3-phase stepper motor

|

|

|

|

|||

|

Auxiliary Equipment

|

Exhaust fan and air exhaust pipe

|

|

|

|

|||

|

Power Supply

|

AC220V/220V+10% 50/6OHz

|

|

|

|

|||

|

Working Environment

|

Temperature:0-45°℃,Humidity 5-95%(No condensate water)

|

|

|

|

|||

Why Choose Us

Anhui Codos

Laser Technology Development Co., Ltd. is a high-tech enterprise with years of experience in R&D, production, sales and technical maintenance in the laser equipment industry. With the professional laser technology as the backing, the company constantly absorbs advanced technology and design concept, and produces and sells laser equipment suitable for various industrial automation production needs. Our company's main products are optical fiber laser cutting machine, fiber laser marking machine, CO2 laser engraving&cutting machine. All products through the CE certification, safe and reliable product quality. In addition to providing standardized products for our customers, we can also provide customized solutions to meet the needs of different customers. Our laser equipment are widely used in industries of electronic, medical, sheet metal, furniture, advertising, craft gifts, architectural model, industrial mold, luxury, decoration, identification, clothing, leather and other industries. We make the high quality advanced machines, we are providing the best after-sale service . And we also offering the most competitive price to all of the customers. "VANK" is known by more and more people. At present, our products have been exported to many countries and regions such as Europe, South America, North America and so on. We have enjoyed the mutual benefit and will move on, and we hope to establish a long term business relations with more and more oversea customers.

Vanklaser at 2024 Canton Fair

Vanklaser at Dubai FEASPA 2024 exhibition

Vanklaser at Printing United Expo 2023

Vanklaser at 2023 Canton Fair

Certifications

High QUALITY ADVANCED EQUIPMENT

We make the high quality advanced machines,we are providing the best after-sale service in China.

And we are also offering the most competitive price to all of the customers."VANK" is known by more and more people.

And we are also offering the most competitive price to all of the customers."VANK" is known by more and more people.

Packing & Delivery

Producing Process

FAQ

1.

Q:Why should you choose us?

A:If you choose us, you will get best quality,best service,best price,best warranty.

2.Q:I'm not familiar with the machine.

A:You just need to tell us materials, working size and thickness.I will recommend you the right machine.

3:How to operate the machine

A:We will deliver English manual and video with the machine to you.If you still need our help,please contact us.

4.Q:How can I get the sample to check you quality ?

A:If you want to marking sample to check the quality, we can help you do this. first you need to provide the logo or design to us, free mark samples can be provided.

5.Q:Do the machine can be customized according my requirements?

A:Sure,we have a strong technical team and have rich experience. Our goal is to make you satisfied.

6.Q:Can you arrange the shipment for me?

A:We can arrange the shipment for our clients accordingly by sea and air. Trading terms FOB, CIF, EXW are available.

Hot Searches