NaN / 0

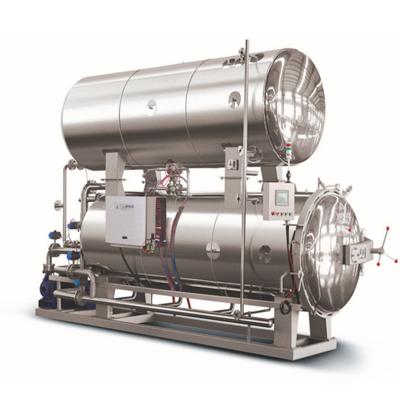

Industrial Water showering food retort/Horizontal autoclave rotary sterilizer pot/canned food retort

Get Latest Price

US$ 10000

≥1 Pieces

Quick Details

Marketing Type:

New Product 2023

Place of Origin:

Henan, China

Brand Name:

OHFU

Voltage:

380V/220V

Product Details

Industrial Water showering food retort/Horizontal autoclave rotary sterilizer pot/canned food retort

Product Description

High temperature food sterilization overview

In the high temperature food sterilization process, sterilize main target is clostridium botulinum, this bacteria can produce fatal damage toxin to human body, which is a heat-resistant anaerobic bacteria, it will lose biological activity within 3 minutes under 121 ℃ environment, lost biological activity at about 6 hours under 100 ℃ environment. The higher the temperature, the shorter bacteria survival time. After scientific test, sterilization at 121 ℃ is more appropriate, the packaging has a good heat resistance at this time, and more good food taste. 121 ℃ sterilization, the food center F value reach at 4, clostridium botulinum will not be detected in the food, meet the commercial asepsis requirements.

The purpose of the steriliz e pot is provide a sealing environment for high-temperature food sterilization at the specified temperature, time and pressure, it must have a good thermal distribution, when sterilizing arbitrary point temperature and average temperature difference should meet the requirements in the sterilization pot. If some point temperature below the average temperature, then the point can not reach the scheduled sterilization F value, the food near this point can not meet the sterilization requirements. Homogeneously thermal distribution is the most important technical target for measure the quality of sterilization pot, which can be measured by thermal distribution analyzer.

When food in high temperature environment, the longer time the worse taste, the more nutrient loss, which requires sterilization pot temperature at each points must be quickly consistent when heatingup, maintain a high degree of F points consistent, so it can quickly end the sterilization process. The cooling process should be fast too, so the food can get away in the shortest possible time from high temperature environment, which requires steriliz e pot scientific and reasonable design water flow, minimize the sterilization process time.

Sterilizer pot specification :

| External installation dimension | L 1 750 * W10 00* H 1 4 00mm |

| Sterilier barrel | diameter 700 mm, length 1200mm |

| Tray size | 1200*450*150 mm (3 trays) |

| Working volume | 0.24 CBM (240 Liters) |

| Control method | electric appliance semi automatic |

| Voltage and frequency | 380V 50HZ 3 phase |

| Power | 30KW |

| Max working temperature | 143 ℃ |

| Max pressure | 68 psi (0.47 Mpa) |

| Material | stainless steel or carbon steel |

| Weight | 350KG |

Performance characteristics of electrical semi-automatic control system sterilizer

1. Semi-automatic control; control sterilization temperature, time, pressure.

2. mechanical safety chain.

3. Mechanical overpressure protection.

4. Intelligent temperature control.

5. Temperature difference inside sterilizer (temperature distribution) ± 0.5 ℃.

Applicable packages: soft package, (CPP + PA, aluminum foil, PET + CPP + PA), glass bottles, tinplate etc.

This thermal distribution diagram shows arbitrary 4 point temperature test results in the sterilizer, after temperature stable, the temperature difference at points ≤ 0.3 ℃)

The sterilizer also need equip with 2 water tanks, 500 liters each, 1 tank storage cold water for cooling, another tank storage hot water for sterilize, 140 degree centigrade high temperature resistant, you can also equipt bigger cold water tank, because it need cold water ciculation for cooling, it will be cooling faster if have more cold water . And a air compressor, air flow 0.17 m3 /min , pressure 10kg .

Packaging & Shipping

Certifications

Our Services

FAQ

Advantages

Hot Searches