NaN / 0

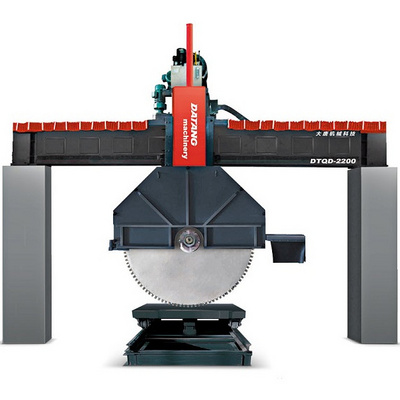

WanLong Machinery QSQ-2200 bridge block cutter Multi-blade Stone Cutting Machine marble cutter for granite marble

Get Latest Price

US$ 25000

≥1 Sets

Quick Details

Model NO:

QSQ-2200/2500/3000

Type:

Stone Cutting Machine

Power:

45KW

Cutting thickness (max):

100mm

Product Details

WanLong Machinery QSQ-2200 bridge block cutter Multi-blade Stone Cutting Machine marble cutter for granite marble

High efficiency for cutting block into slabs with multi-blade combination, this machine is the ideal equipment for producing large slabs.

One of its main features is that trolley is not necessary when cutting. You can lie the block on the ground, and the processing is smooth, reliable and no shaking. You can also cutting several blocks of different sizes together at the same time.

Owing to the special design, the function of slab slicing is achieved by the crossbeam movement on the side beams. This is totally different from other machines on which the slab slicing is by trolley feeding. There precise cutting and less maintenance are available by this machine.

Feeding trolley with rails is available upon request.

Feature

Mechanical system

l Wide-span crossbeam of bridge structure, large block cutting available

l Crossbeam is made of strong cast iron to avoid distortion after long-term use

l Dustproof design of the slide track ensures the precise guide movement & long lifespan

l Double V-Shape guide rails enhance the smooth cutting and movement

l Precise movement of cutting head in horizontal direction by precision rack & gear

l Guide rail on the crossbeam is in oil bath and protected from water and dust

Electrical system

l Cross movement of the cutting head on the crossbeam is driven by motor equipped with OMRON rotary encoder by which the precision is guaranteed

l Installed with PANASONIC frequency transducer and OMRON PLC, programmable and fully automatic, stability and flexibility guaranteed

l Friendly human-machine interface design, easy operation

l C.E. Certificate

Technical Parameter

|

|

QSQ-2200 |

QSQ-2500 |

QSQ-3000 |

|

Max. blade diameter/mm |

2200 |

2500 |

3000 |

|

Max. cutting length/mm |

3200 |

3000 |

2500 |

|

Max. cutting width/mm |

1800 |

1800 |

1800 |

|

Max. cutting height/mm |

950 |

1100 |

1350 |

|

Max. No. of blades |

9 |

3 |

1 |

|

Main motor power/kw |

55 |

55 |

55 |

|

Power requirement |

3 Phs 380V 50Hz(other is available) |

||

|

Overall dimension (LxWxH)/mm |

7300X3800X5500 |

7300X3800X5500 |

7300X3800X6100 |

|

Total Weight/kg |

10,000 |

11,000 |

12,000 |

Production Capacity

Gr anite of medium rigidity: 70-75 square / 24h

Granite of hard rigidity: 40-46 square / 24h

Marble: 110-120 square / 24h

Blade Install

QSQ-2200, 2L+2M+2S, such as 2x2200mm+2x1800mm+2x1000mm or other

QSQ-2500, 1L+1M+1S, such as 1x2500mm+1x1800mm+1x1000mm or other

QSQ-3000, 1x3000mm, or the same as QSQ-2200

Other combinations are available

Packing:

Sea worthy packaging, fully wrapped with waterproof membrane and air bubbles

Two units in one 40’ GP container

Lead Time

One month

Price

QSQ-2200 US $20,300/unit

QSQ-2500 US $20,710/unit

Above prices are based on FOB Xiamen, China

Payment

50% in advance by T/T, balance by T/T before shipment

Company intruction

Diamond tools

:Wanlong's mission is to make no stone hard to cut in the world, to help customer save production costs. More than 10 years in the line of diamond tools industry, Wanlong’s technological innovation improves the cutting efficiency, and save the cost for end-users.

Stone Industry

: Wanlong developed Aluminum Plastic Laminated Panel, Honeycomb Laminated Panel, Ceramic Thin Marble Panel, Fiberglass Thin Granite Panel, Fire Proof Thin Granite Panel and other new stone products. Not only save stone (3-5mm super thin stone, the original 1-3cm reduced to 3-5mm), but also let stone products have properties (impact resistance, high-temperature resistant, fire resistant, light weight, large single size 140x280cm ), expanding the application of the stone (high-rise building interior wall decoration, airplane and yacht interiors).

Machinery

: Wanlong mechanical's mission is to provide customers with advanced technology solutions for efficient tools production. 18 years’ practical experience in stone machinery industry contributes to rich experience and Technological advantage of diamond tools. Wanlong machinery will fit the needs of customers with more sophisticated services to fulfill the mission.

Advantages

Verified Information

This information was Verified by

Bureau Veritas

and is valid for the following period:

2015/05/16 --- 2016/05/15

The information below covers both the Gold Supplier and its related companies, which are defined according to china laws and regulations, and which will also be clearly displayed in the

full report >>

The competitive advantage of product line:

Our products are mainly exported to Southeast Asia, Mid East, accept customers' customization.

Production Capacity:

| Product Line Name | Production Line Capacity | Actual Units Produced(Previous Year) |

|---|---|---|

| Diamond Segment, Diamond Cutting Blade | USD 15,000,000.00/Year | USD 11,000,000.00 |

Export Market Distribution:

| Market | Revenue(Previous Year) | Total Revenue (%) |

|---|---|---|

| North America | USD 800,000 | 7.2 |

| South America | USD 6,500,000 | 59.1 |

| Mid East | USD 3,300,000 | 30.0 |

| Western Europe | USD 400,000 | 3.7 |

Production Machinery:

.0| Machine Name | Brand & Model No. | Quantity | Number of Year(s) Used | Condition | |||||

|---|---|---|---|---|---|---|---|---|---|

| Welding Frame | GHA280/1300 | 10 | 10.0 | Acceptable | |||||

| Press Type Hydraulic Press | MYS-200T | 13 | 10.0 | Acceptable | |||||

| Sintering Machine | PYT-2000C | 5 | 10.0 | Acceptable | |||||

| Mix Blender | No Information | 18 | 10.0 | Acceptable | |||||

| Industrial Personal Computer | EPC-102 | 14 | 5.0 | Acceptable | |||||

| Drilling Machine | No Information | 3 | 10.0 | Acceptable | |||||

| Lathe | No Information | 2 | 10.0 | Acceptable | |||||

| Gantry Cutting Machine | No Information | 5 | 10.0 | Acceptable | Welding Frame | GHA280/1300 | 10 | 10.0 | Acceptable |

Testing Machinery:

| Machine Name | Brand & Model No. | Quantity | Number of Year(s) Used | Condition |

|---|---|---|---|---|

| Electric Rockwell Hardness Machine | HR-150DT | 6 | 11.0 | Acceptable |

| Stereoscopic Microscope | GL99B1 | 3 | 7.0 | Acceptable |

| Superhard Material Impact Tester | CMG-II | 1 | 7.0 | Acceptable |

| Electromagnetic Vibration Sieve Machine | No Information | 1 | 4.0 | Acceptable |

| High Temperature Furnace Integration Program | No Information | 1 | 4.0 | Acceptable |

| Diamond Heating Tube Furnace | CYRL-1 | 1 | 4.0 | Acceptable |

| Tensile Tester | No Information | 1 | 4.0 | Acceptable |

Hot Searches