NaN / 0

CNC 5Axis Bridge Cutter Granite Marble Stone Cutting Machine for granite marble

Get Latest Price

US$ 3000

≥1 Sets

US$ 2990

≥5 Sets

Quick Details

Type:

Bridge Saw

Power:

7.5 KW

Cutting thickness (max):

100mm

Place of Origin:

Shandong, China

Product Details

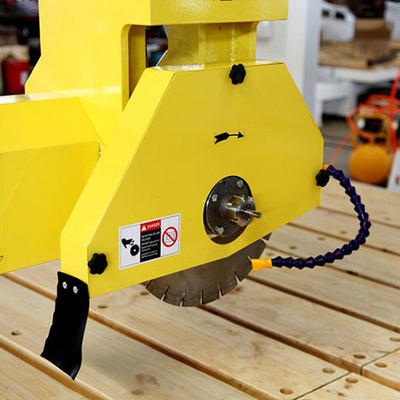

5axis cnc bridge saw 4 axis stone cutting polishing carving slab machinery for marble granite countertops and sink

Product Description

UBO 5axis cnc bridge cutting machine is new generation multi-function processing machine which is associated to be designed and manufactured between OMC and research institute of famous college. With pattern operation and advanced control system and synchronous CNC control system, the machine can be easily operated easily without knowing complicated CNC knowledge.

This machine can be used to realize some advanced functions like : cutting line, chamfering, drilling, profiling, 3D profiling, and edge profiling, which can be used to small processing factory and countertop shops.

Feature Of Machine

1. Compact size without needing the ground base.

2. With advanced touch Touch operation CNC control system and all pattern operation, the machine can be operated without professional operators.

3. With powerful functions, the machine can work almost all the jobs of a small factory.

4. With less electricity and more efficiency, the cost is decreased much.

5. High quality accessories and electric parts are used to secure long service life and low cost.

6 . intelligent processing cross-border protection, to prevent the mechanical impact due to excessive design documents processing.

7 . Diversity control can separately control the processing speed, idling speed, cutting speed, greatly improving the quality of speed, greatly improving the quality of speed, greatly improving the quality of processed product and processing efficiency.

|

Programming |

Touchscreen, DXF Importing |

|

Control System |

CNC 5axis |

|

Power |

4/7.5 kW |

|

Rotation Speed |

2800rpm |

|

Blade Size |

350 mm |

|

X Axis Stroke |

3 2 00mm (or 3500mm) |

|

Y Axis Stroke |

2000mm |

|

Z Axis Stroke |

50 0mm |

|

B Axis Rotation |

Auto 0-90 degree chamfer ( automatic ) |

|

A Axis Stroke |

360 Rotation ( automatic ) |

|

X Axis Cutting Speed |

1- 4 000mm/min |

|

Y Axis Cutting Speed |

1- 4 000mm/min |

|

Z Axis Cutting Speed |

1-1000mm/min |

|

A Axis Rotating Speed |

0-7r/min |

|

Cutting Thickness |

100mm |

|

Cutting Accuracy |

0.2mm |

|

Working Table Size |

3 0 00*2000mm |

|

Dimension |

51 00*2 9 50*2100mm |

|

Weight |

285 0k |

Note:

1. Delivery time: 20 days after receipt of 30% deposit

2. Warranty: 3year (excluding easily damaged parts)

3. Voltage: According to clients requirements.

4. Trade terms: EXW, FOB, CFR, CIF, DDU, FCA

5. Payment terms: T/T (30% T/T in advance, the balance paid before leaving our factory )

6. This price includes one set of installation tool and one set of processing tools, not include air pump.

7. If you need tools for profiling and polishing, we will send drawing of edge shapes for your option.

8. If you need extra blades, price is as below.

9. We offer 2 sets free tools.

|

Tools |

Price |

|

|

|

Blade -- 350mm diameter |

$60.00 |

|

Polishing wheel |

$15.00 |

|

|

Milling cutter--10mm diameter |

$ 6 .00 |

|

|

Drilling tool--35mm diameter |

$5.00 |

|

Full automatic five axis infrared bridge cutting machine, multi language conversion , table processing by one machine, x-y-z-a-b five axis linkage , more widely used, simple operation and stronger practicability.

used for cutting, chamfering, edge grinding, slotting, drilling, circular arc and other special-shaped processing .

Main Parts :

Packaging & Shipping

- Nude with Plastic Film and Wire Fixing

- 20GP Load 1 Set

- Qingdao Port Shipment

- 3 Year Warranty

- OEM&ODM Available

- Assemble Tools Included

- Spare Parts Available

Buyer Feedback

FAQ

Q

1

: How can I get an accurate price?

Please tell us your cutting material and the working size.

Q

2

: How is your after sales service?

Our sales are online for 24-hours. We can also supply overseas install service. Also we have more than 10 countries warehouse and department.

Q

3

: How long is the delivery time?

Generally

15

~

2

5

working

days.

Q

4

: Can I get a machine according to my own requirements?

Sure.We accept OEM and ODM

Q

5

: If my machine is broken. Can you repair it for me?

Yes. We have free traning online. If there is big trouble with your machine in the warrenty time, we can repair it.

Q

6

: How is the quality of your machine?

Our machine adopts heavy lathe bed, and each part is processed by CNC machining center, which greatly improves the accuracy of machine operation.

Hot Searches