NaN / 0

Double Walled Cooling Jacket Conical Beer Fermenter Stainless Steel Fermentation Tank 50l 75l 100l 200l 400l 500l 1000l

Get Latest Price

US$ 1500

≥1 Sets

US$ 1200

≥3 Sets

Quick Details

Place of Origin:

Shandong, China

Brand Name:

TONSEN

Voltage:

Adjustable

Power:

15-70Kw Depends

Product Details

Double Walled Cooling Jacket Conical Beer Fermenter Stainless Steel Fermentation Tank 50l 75l 100l 200l 400l 500l 1000l

Description

Tonsen is the leading Microbrewery equipment supplier in China, our service include the brewery design, equipment manufacture, installation at site and brewing technology transfer.

We provide complete beer brewing solutions that include: malt handling system, brew house system, beer fermenting/storage system, cooling system, cleaning system, control system, package line.

Tonsen has been exported to more than 20 countries, which include USA, Canada, UK, France, Germany, Holland, Slovakia, Belgium, Argentina etc.

|

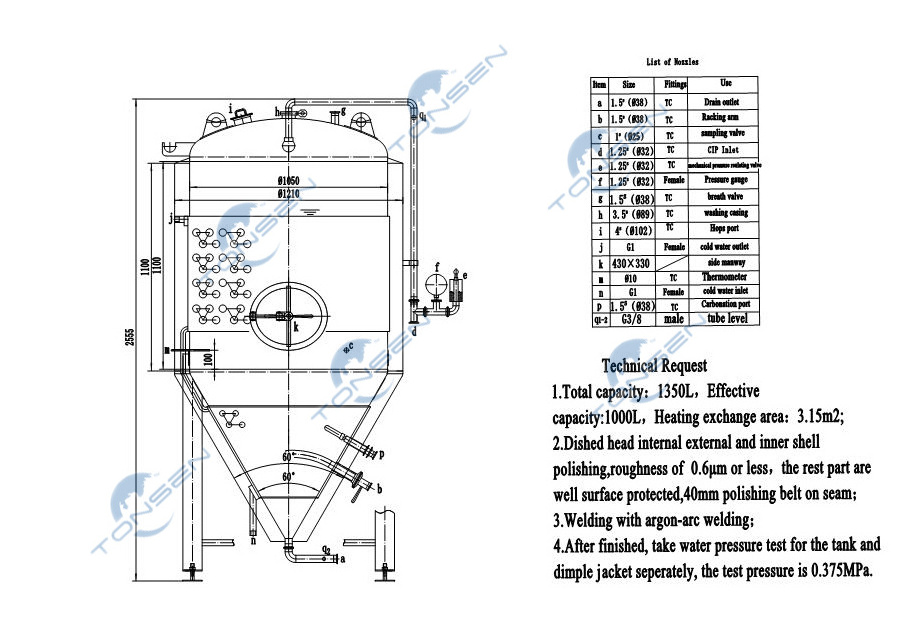

Technical drawing for 1000L /10HL conical fermenter

|

|

|

|

|||

|

Effective capacity

|

1000L

|

Thickness

|

80mm

|

|||

|

Total capacity

|

1300L

|

Interior thickness

|

3mm

|

|||

|

Boundary dimension

|

φ1210×H2550

|

Exterior thickness

|

2mm

|

|||

|

Material

|

SUS304, brushed outer shell

|

Manhole

|

Side/Top manhole

|

|||

|

Insulation

|

polyurethane

|

|

|

|||

*Dimple plate cooling jacket on tank body and conical bottom

*Dished head and taper angle 60°

*Temperature sensor TP100

*Inner tank mechanical polishing and out plate surface protection ribbon polished on welds

*1pcs x Hops adding port

*1pcs x breathing valve

*1pcs x mechanical pressure regulation valve

*1pcs x sample valve

*1pcs x racking arm

*1pcs x pressure gauge

*1pcs x CIP spray device

*1pcs x drain outlet bottom

*4 heavy duty legs with leveling pad

*Working pressure: 1bar

Note

:1.1Hectolitre(HL)=100Liter; 1Barrel(BBL)=117Liter

2.Water supply: water supply, for mashing, cooling, cleaning

3. Electricity supply: 3-phase electricity

4. Voltage/frequency adjust to your local power supply

5.Material: malted barley or wheat, hops, water

|

Fermentation Tank

|

Volume in US Gallon

|

Diameter

|

Height

|

|

100L Fermentation Tank

|

26US Gallon

|

620mm

|

1600mm

|

|

200L Fermentation Tank

|

53US Gallon

|

820mm

|

1800mm

|

|

300L Fermentation Tank

|

79US Gallon

|

960mm

|

1900mm

|

|

400L Fermentation Tank

|

106US Gallon

|

960mm

|

2100mm

|

|

500L Fermentation Tank

|

132US Gallon

|

1010mm

|

2100mm

|

|

600L Fermentation Tank

|

159US Gallon

|

1060mm

|

2150mm

|

|

800L Fermentation Tank

|

211US Gallon

|

1060mm

|

2550mm

|

|

1000L Fermentation Tank

|

264US Gallon

|

1210mm

|

2550mm

|

|

1200L Fermentation Tank

|

317US Gallon

|

1360mm

|

2550mm

|

|

1500L Fermentation Tank

|

396US Gallon

|

1560mm

|

2620mm

|

|

2000L Fermentation Tank

|

528US Gallon

|

1560mm

|

3100mm

|

|

2500L Fermentation Tank

|

660US Gallon

|

1760mm

|

1760mm

|

|

3000L Fermentation Tank

|

793US Gallon

|

1760mm

|

3500mm

|

|

3500L Fermentation Tank

|

925US Gallon

|

1760mm

|

3750mm

|

|

4000L Fermentation Tank

|

1057US Gallon

|

1760mm

|

4050mm

|

|

5000L Fermentation Tank

|

1321US Gallon

|

1760mm

|

4540mm

|

|

6000L Fermentation Tank

|

1585US Gallon

|

1960mm

|

4700mm

|

|

100HL Fermentation Tank

|

1849US Gallon

|

1960mm

|

5200mm

|

Detailed image

1.Polishing

-Inside Polishing: Overall polishing to 0.6μm without dead corner .

-Outside Polishing: Mirror polishing, smooth enough and passivating treatment.

-Purpose: Make sure the inner tank smooth enough to avoid form any dead cornor which caused bad taste in the wort beer. Outer

tanks looks more like an artwork.

2.100% WIG Welding

-All welding is TIG welding.

-All welding is Full welding.

-All welding is double side welding.

-Purpose: The use of argon on the protection of metal welding material, So that welding can not be in contact with oxygen in the

air, thus preventing the oxidation of welding consumables.Which Makes tanks durable and strong.

-Inside Polishing: Overall polishing to 0.6μm without dead corner .

-Outside Polishing: Mirror polishing, smooth enough and passivating treatment.

-Purpose: Make sure the inner tank smooth enough to avoid form any dead cornor which caused bad taste in the wort beer. Outer

tanks looks more like an artwork.

2.100% WIG Welding

-All welding is TIG welding.

-All welding is Full welding.

-All welding is double side welding.

-Purpose: The use of argon on the protection of metal welding material, So that welding can not be in contact with oxygen in the

air, thus preventing the oxidation of welding consumables.Which Makes tanks durable and strong.

Part of Auxiliaries:

Tonsen offers all necessary peripheral equipment to ensure that your brewery / Brewpub has everything it needs for a high quality brew and the means to give your clients the best drinking experience.

Project Recommend

Middle Beer Brewery Equipment

We are factory supplied with good quality, more competitive price and installation service. Lifetime guarantee are assured.

Whether you are creating a business or brewery renovation project, come here!

A perfect solution is always for you!

Our Service

1.

Pre-sales Service:

Technical Drawing

We will offer Technical Drawings of each tank based on the equipment layout .

Layout design

Sent us your building floor plan, or the sketch, or tell us the size (length, width, height), we will offer you an

equipment footprint according to your requirement.

equipment footprint according to your requirement.

3D Drawing

We will 3D effective sketch to make sure ensure you have a more intuitive experience.

2.After-sales service

-We can provide weekly production report to let you clear of production progrss and production details;

-We will do equipment test and test report available for you;

-Providing piping connection drawing and English operation manuals;

-Providing equipment installation, debugging, and personnel training service;

-We can help you to arrange transportation till to your location;

-Main machine guarantee for three years; Accessories and electronic components will have one year free warranty; Supply lifetime maintenance and technical service.

-We will do equipment test and test report available for you;

-Providing piping connection drawing and English operation manuals;

-Providing equipment installation, debugging, and personnel training service;

-We can help you to arrange transportation till to your location;

-Main machine guarantee for three years; Accessories and electronic components will have one year free warranty; Supply lifetime maintenance and technical service.

Hot Searches