NaN / 0

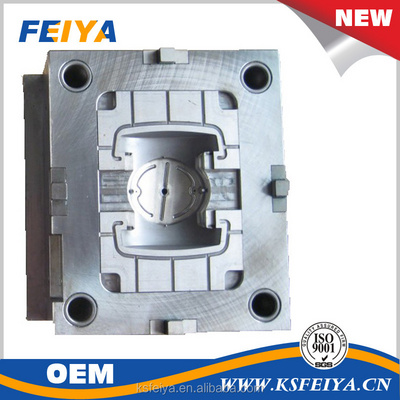

Factory Custom PP Plastic/PP Plastic Injection Molding custom plastic injection mold

Get Latest Price

US$ 150

≥100 Pieces

Quick Details

Shaping Mode:

Plastic Injection Mould

Place of Origin:

Jiangsu, China

Brand Name:

Feiya

Model Number:

pvc,oem,pp,abs

Product Details

Product Description

Specification

|

Name

|

Factory Custom PP Plastic/PP Plastic Injection Molding custom plastic injection mold

|

|

Place of Origin

|

China Jiangsu

|

|

Brand Name

|

FEIYA

|

|

Model Number

|

customized

|

|

Product Material

|

ABS,PP,PC,PE,POM,PU,PVC,TPU, etc

|

|

Keyword

|

injection fabrication for medical equipment battery cover

|

|

Mould base

|

European Standard

|

|

Mould material

|

SKD11/51/61,SKH-9,S136, NAK80,XW-42,2738,8407,etc.

|

|

Design software

|

UG,UG, PROE ,CATIA, SOLIDWORK, CAD,etc.

|

|

Mould life

|

300000-1000000shots

|

|

Tolerance

|

+/-0.001mm

|

|

Surface treatment

|

as customer's requirments

|

|

mould type

|

injection fabrication for medical equipment battery cover

|

|

Processing equipment

|

CNC machine,Automotic lathe machine,EDM machine,Wire-cutting machine,Milling/Grinding machine,Punching/injection

machine,Ultrasonec cleaning machine,etc. |

|

Detection equipment

|

Projector,Calliper,Height gauge,Screw gauge,Hardness gauge,etc

|

|

Cavity

|

Single / Multi cavities,as customer's requests.

|

|

Runner

|

Hot / Cold

|

|

Mould life

|

300000-1000000shots

|

|

Specification

|

20 years machining parts processing experience;Precision tolerance less than 0.001mm;Depends on customer’s requirements.

|

|

Delivery

|

Shipping sample in 30 days after payment,or according to customer's requests.

|

|

Package

|

PE bags add export carton for parts,Wooden case for mold,or as customer's requests.

|

How to customize products

Why Choose Us