NaN / 0

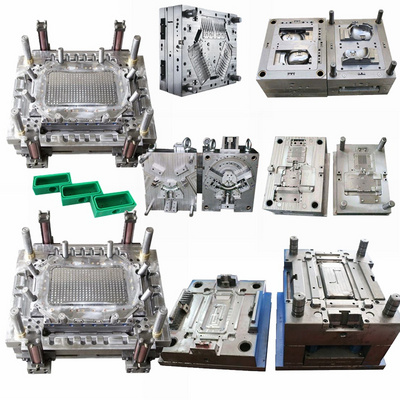

Factory Mold Making Custom Professional Plastic Injection Mould Injection Mold For Plastic Molding Parts

Get Latest Price

US$ 1000

≥1 Sets

Quick Details

Shaping Mode:

Plastic Injection Mould

Place of Origin:

Chongqing, China

Brand Name:

XBC

Model Number:

CUSTOM

Product Details

PRODUCT

We are a professional plastic injection mold factory.

Main Business:

1.

OEM/ODM customized plastic injection mold;

2.

Customized plastic molding parts;

3.

CNC machining service;

4.

Die casting mold, etc.

PRODUCT APPLICATION

PRODUCT PARAMETERS

|

Mould

|

|

|

|

|

||||

|

Mould core

|

P20/718H/2738/H13/NAK80/420/2343/2344/S136

|

|

|

|

||||

|

Mould base

|

45#/S50C

|

|

|

|

||||

|

Cavity

|

Single/Multi

|

|

|

|

||||

|

Runner

|

Hot/Cold

|

|

|

|

||||

|

Precision

|

±0.01mm

|

|

|

|

||||

|

Mould Life

|

50,000-1,000,000 shots

|

|

|

|

||||

|

Lead Time

|

15-60 days

|

|

|

|

||||

|

Surface Treatment

|

Polishing, Painting, Chroming, Anodizing, Brushing, Silk Screening, Laser Cutting, Texture, etc.

|

|

|

|

||||

|

Specification

|

Customized

|

|

|

|

||||

|

Packaging

|

Wrapped with a layer of anti-rust film, packed in a wooden box.

|

|

|

|

||||

|

Shipping

|

By sea, air or land according to customer's requirement.

|

|

|

|

||||

|

Plastic Parts Product

|

|

|

|

|

||||

|

Material

|

ABS/PP/PVC/PE/PC/PA/PMMA/POM/TPU/PET

|

|

|

|

||||

|

Shaping Mode

|

Injection molding

|

|

|

|

||||

|

Free Samples

|

Available

|

|

|

|

||||

|

Packaging

|

Carton or wooden box according to product weight and customer's requirement.

|

|

|

|

||||

|

Shipping

|

By express, sea, air or land according to customer's requirement.

|

|

|

|

||||

|

Mainly Used

|

Housings, containers, lids, fittings and any other injection molded parts including as below

auto/motorcycle lights, industrial machinery parts, automotive/motorcycle parts, power-tool housing, disposable razors, electrical switches, automotive dashboards, drug inhalation units, telephone handsets, bottle lids/closures, battery casings, etc. |

|

|

|

||||

|

Market Scope

|

Industrial, consumer, lighting, healthcare, mechanical, water treatment, appliance, plumbing, motors, gears, electronics, fasteners, etc.

|

|

|

|

||||

PRODUCTION PROCESS

DFM Report for Product

3D Design/2D Drawings

Technical Analysis

3D Modeling Mold Flow Analysis

Material Preparation

Mold Assembly

Mold Test

Quality Inspection

ORDER PLACEMENT PROCESS

1. Inquiry Stage

3D drawing/sample/idea

analyze and discuss project

2. Quotation Stage

confirm and quote

3. Mold Making Stage

DFM confirmation, tooling design, CNC machining, wire cutting, EDM, surface treating, mold

assembly

.

4. Sample Approval Stage

Inspect sample size, assemble the test sample and deliver to customer.

Make the appearance effect until the customer is satisfied.

Make the appearance effect until the customer is satisfied.

5. Mass Production Stage

mass production of plastic injection molding

6. Delivery Stage

Packing with standard export or customized packaging.

Shipping according to customer's requirement.

PACKAGING&DELIVERY

Mold Packaging

Firstly, assemble the mold, clean it well, apply anti-rust mist or grease on the mold, then cover it with a film, and put it in a stable wooden box.

Molding Product Packaging

Firstly, wrap products with translucent thin foam and put them in a plastic bag, then put them in cartons with thin sponge boards to prevent scratches.

COMPANY PROFILE

Chongqing Xingbang Hengxiang Mold Co., LTD. was founded in 2013 in Chongqing, China, with 50+ sets of equipment and 150+ employees. We have more than 20 years of technology and experience in plastic injection moulds. We specialize in the plastic injection moulds, production of injection moulding product, CNC machining and die casting moulds.

We are a mold manufacturer with professional R&D teams, so we have independent research and development capabilities. We pay more attention to quality and practicality, which is what we have been insisting on for so many years. For our factory, the mold production process is smooth, and the molds are characterized by precision, durability, and fast injection molding and so on. The injection molding products we manufacture, including auto, motor and bicycle accessories, machinery parts, any shells and lids and any other plastic products, are novel, high-quality, durable, etc. Our products can be used in various industries, such as automobile and motorcycle, industrial machinery parts, new energy, medical, artificial intelligence (AI), electronic technology, renewable energy, household appliances and other industries.

We have excellent resource integration capabilities to provide customers with one-stop service, solving the problem of needing to contact multiple suppliers for customers. At the same time, our factory has professional quality inspection and after-sales teams, which provide a guarantee for our company to export high-quality products.

Please feel free to contact us if you have any purchase or design needs for injection molds or plastic parts products. We will always be there for you 7x24.

We are a mold manufacturer with professional R&D teams, so we have independent research and development capabilities. We pay more attention to quality and practicality, which is what we have been insisting on for so many years. For our factory, the mold production process is smooth, and the molds are characterized by precision, durability, and fast injection molding and so on. The injection molding products we manufacture, including auto, motor and bicycle accessories, machinery parts, any shells and lids and any other plastic products, are novel, high-quality, durable, etc. Our products can be used in various industries, such as automobile and motorcycle, industrial machinery parts, new energy, medical, artificial intelligence (AI), electronic technology, renewable energy, household appliances and other industries.

We have excellent resource integration capabilities to provide customers with one-stop service, solving the problem of needing to contact multiple suppliers for customers. At the same time, our factory has professional quality inspection and after-sales teams, which provide a guarantee for our company to export high-quality products.

Please feel free to contact us if you have any purchase or design needs for injection molds or plastic parts products. We will always be there for you 7x24.

FAQ

Q1. Are you a factory or a trading company?

-We are a factory with one-stop OEM/ODM service.

Q2. What do you need for the quotation?

-We need 2D/3D drawing, specific sample,

product pictures or similar pictures with size specifications.

Q3. Can you help me to design the product or improve my design

?

-Yes, we have a professional design team to help you design the product and improve your design.

Q4. Do you provide free sample?

-Yes,

we provide free samples, but we don't bear the shipping cost.

Q5. When will you ship the mold, the sample and the products?

-Normally, it takes 15-60 days to make the mold, and then we will send you the samples for approval. And

plastic products are according to quantity.