NaN / 0

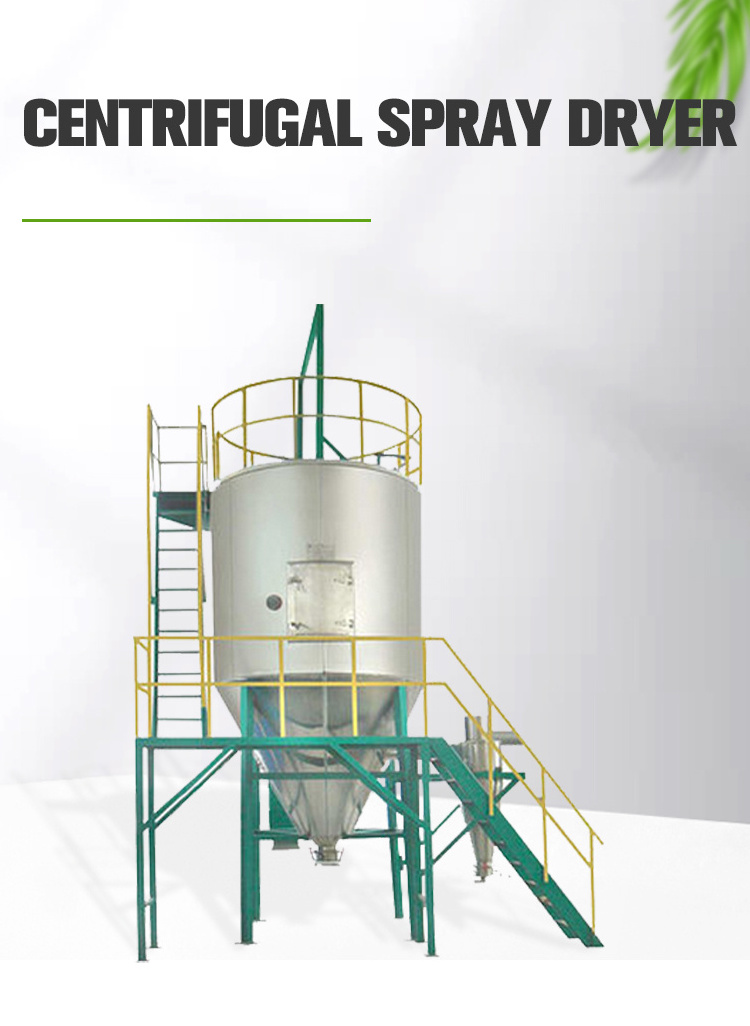

Nano whey protein powder spray dryer small milk powder making machine

Get Latest Price

US$ 26600

≥1 Sets

US$ 15805

≥3 Sets

US$ 8770

≥10 Sets

Quick Details

Type:

Drying Oven

Place of Origin:

Shandong, China

Brand Name:

KR

Voltage:

110/220/380/415/480 V

Product Details

Dear customers: welcome to consult "KRUGER RANGO" brand

High Standard

Centrifugal

Spray Drying machine

24 hours online for you; > 20 years experience ; Delivery time < 7 days

Main features of KRUGER RANGO c

entrifugal spray

drying machine

:

1. The whole machine is made of

SUS304 stainless steel

;

2. General selection of heat source: electric heating; Users can also choose steam heating or other heating methods (

users only need to tell us in advance what is your preferred heating method

);

3. The power consumption of the machine is very small: the min power consumption can reach

2.2Kw

;

4. Our delivery cycle is very short: the shortest delivery time is

7 days

;

5. Our warranty service lasts for a long time: up to

3 years

; If the parts are damaged within three years, we will immediately express the new parts to you;

6. If you are interested in this equipment, please feel free to ask us for advice; Our service staff will provide answers

online 7 * 24h

;

Product Paramenters

|

Items

|

Details

|

|

|

|

|||

|

Pruduce Name

|

High Standard Centrifugal Spray Drying machine

|

|

|

|

|||

|

Application

|

Drying raw materials from Liquid to powder, widely used in many field , such as : Plastics Processing,Food Processing,Food& beverage,etc.

|

|

|

|

|||

|

Inlet temp

|

150-350℃

|

|

|

|

|||

|

Outlet temp

|

60-120℃

|

|

|

|

|||

|

Feature

|

High Productivity

|

|

|

|

|||

|

Water evaporation capacity

|

5 kg/h

|

|

|

|

|||

|

Raw material

|

Liquid form material, extracts, extractum

|

|

|

|

|||

|

Heating method

|

Electrical / gas / steam heating method

|

|

|

|

|||

|

Power voltage

|

380V50Hz3P(can be customized)

|

|

|

|

|||

|

Equipment material

|

SUS304 stainless steel

|

|

|

|

|||

|

Machine Size(L*W*H)

|

4000*3500*4800mm(can be customized)

|

|

|

|

|||

|

Weight

|

About 1000kg

|

|

|

|

|||

|

Warranty time

|

3 years

|

|

|

|

|||

Products Description

Industrial

Centrifugal Spray Drying machine

The spray drying is the technology widely used in the liquid technology shaping and in the drying industry. Equip with imported Schneider electrical components,PLC control system,self-priming peristaltic pump and oil-free air compressor,is suitable for producing solid powder or particle products from liquid materials drying,such as emulsion, suspending liquid, liquor and so on.

The advantages of Kruger Rango Barand

centrifugal spray drying machine

are

:

1).Stainless steel material, arc corner design and polyester powder coated shell, prevents corrosion of acidity and alkaline air effectively.

2). Imported Schneider electrical components which is more stability.

3). PLC control system, make your research more easier and efficient.

4). Build in oil-free air compressor, without any noise.

5). Self-priming peristaltic pump, avoid secondary pollution, make sure whole process conducted steady.

6). Narrow size distribution, more than 95% of the dry powders are in the same range of particles.

7). Innovative tower wall purging device, improves the material recycling rate.

8). In the hot-air flow, 95%~98% of water can be evaporated at a moment. You can finish material drying only in several seconds.

The

centrifugal spray drying machine

working principle:

After filtering and heating, the hot fresh air enter into the air distributor at the top of drying chamber, distributed in spiral way uniformly from up to down. At the same time, the feeding liquid is pumped to the top atomizer, then be sprayed to extremely fine mist liquid drop. Through the short time of direct contact with hot air, the moisture evaporated at once, the solid remains to be powder. The dry powder will be discharged continuously from the bottom of drying tower and cyclone collector, the exhaust air will be discharged after cleaning.

Notes:

Customers can choose the way of heat in accordance with the conditions of local energy source and the way of dust removing in accordance with the conditions of raw material.

Application field

The spray dryer is mainly used for the research and production of micro powder in food, biology, beverage, chemical industry and material.

Such as the tea powder, milk powder, aloe powder, pumpkin powder, flavor powder, coffee powder, etc.

Details Images

High

centrifugal

standard

spray drying machine

High standard centrifugal spray drying machine

2.

It is widely used in drying Beverages, Flavours and Colouring, Milk and Egg Products, Plant and Vegetable Extracts, Heat sensitive Materials, Plastics, Polymers and Resins, Perfumes, Ceramics and Advanced Materials, Soaps and Detergents, Blood, dyestuffs, Food Stuffs, Adhesives, Oxides, Textiles, Bones, Teeth and Tooth Amalgan and many others.

Details of

high standard centrifugal spray drying machine

Technical Parameters

The Spray Drying Machine

Features:

At a high speed of drying, after the spraying of the liquid material , the surface area of the material will be increased greatly. In the hot-air flow, 95%-98%of water can be evaporated at a moment. The time of completing the drying needs only several seconds.

Products with good uniformity, mobility and solubility, high purity, good quality. The production procedures are simple and the operation and control are easy. The liquid with the moisture contents 40-60%(for special materials, The contents may reach 90%)can be dried into the powder or particle products once a time. After the drying, there is no need for smashing and sorting, so as to reduce the operation procedures in the production and to enhance the product purity. The product particle diameters, looseness and water contents can be adjusted through changing the operation condition in a certain scope. It is very convenient to carry out the control and management.

Product packaging

1.Cargo Packaging

My dear customers, We are pleased to offer you customized items

*shipping mark;

*Logo;

*Professional QC to help you exam the goods before loading.

*Professional QC to help you exam the goods before loading.

2.Shipping Way

*Door to door.

*

LCL Cargo: By Sea/Air;

*FCL Cargo,Port to Port by sea;

*Customer freight agent or negotiable shipping way.

Customers can use your own shipping agent.

*FCL Cargo,Port to Port by sea;

*Customer freight agent or negotiable shipping way.

Customers can use your own shipping agent.

If you need our help, we can provide you the reliable shipping company.

Certifications

Strength Of Kruger Rango Company

After more than 20 years of hard work, Kruger Rango has achieved gratifying results in the field of food machinery and equipment manufacturing:

The main products are:

fruit and vegetable processing production line equipment; various drying equipment; smoking furnace, pulverizer, packaging machine and other products

;

kruger rango products are especially well received by North American customers, South American customers, European customers, Southeast Asian customers, and Australian customers;

The kruger rango team is willing to dedicate its products and technologies to each customer to help customers solve the equipment problems they face.

As long as you consult us: we will definitely serve you to the end, we promise:

7*24h online to answer your inquiries

.

Hot Searches