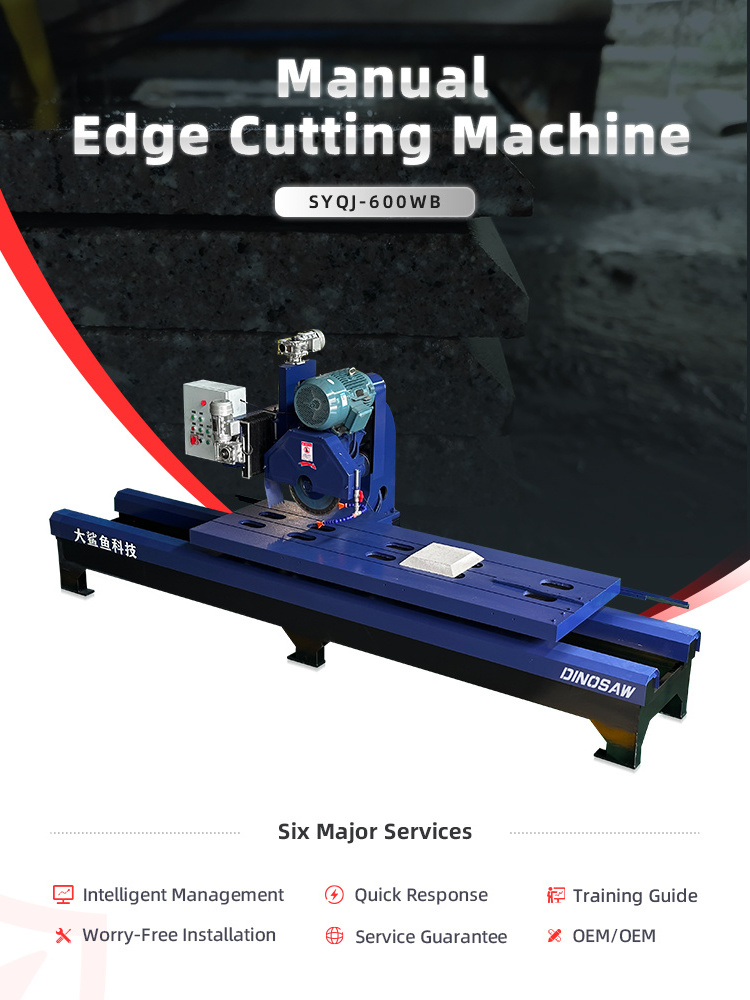

45° cut

This machine can cut with 45°chamfer. it is equipped with guide rail of oil-impregnation sealed type and main shaft of oil lubrication type. It has compacted structure which makes it easy to move.