NaN / 0

Full Powder Coating Systems Semi-automatic Production Powder Coating Plant Line For Flat Shape Metal Products

Get Latest Price

US$ 8000

≥1 Sets

Quick Details

Machine Type:

Curing oven

Warranty of core components:

2 Year

Place of Origin:

China

Brand Name:

Aizhou

Product Details

Product Description

Name:

Powder Coating Curing oven

A powder curing oven is a specialized oven used in the powder coating process to cure or "bake" the powder coating onto the surface of a workpiece. After the powder is electrostatically sprayed onto the workpiece, it is transferred to the curing oven. The curing oven heats the workpiece to a specific temperature for a certain amount of time to melt and fuse the powder particles, creating a durable and smooth coating.

A powder curing oven is a specialized oven used in the powder coating process to cure or "bake" the powder coating onto the surface of a workpiece. After the powder is electrostatically sprayed onto the workpiece, it is transferred to the curing oven. The curing oven heats the workpiece to a specific temperature for a certain amount of time to melt and fuse the powder particles, creating a durable and smooth coating.

we according products characters and customer's requirements to design the powder coating line:

①

Energy options: Gas, LPG, Electric, Coal, etc.

②

Transportation method: ground rail, conveyor trolley, top rail, etc.

③ Size:

Small, medium, and large.

Our Service

|

.Project Management Service

|

We will document your project, from product design, manufacturing, packaging, transportation, assembly, operation and after-sales service, we believe that high-quality service should not stop at sales.

|

|

.Design service

|

We have an experienced design team who have designed hundreds of domestic and foreign projects and can provide you with the best project solution.

|

|

.Installation Service

|

Our engineers have hundreds of overseas service experience, and our excellent distribution network can provide you with hassle-free installation and start-up services.

|

|

.Technical Support Service

|

We have experienced technicians with strong technical background and on-site problem-solving ability to ensure timely response and handling of any equipment problems you encounter.

|

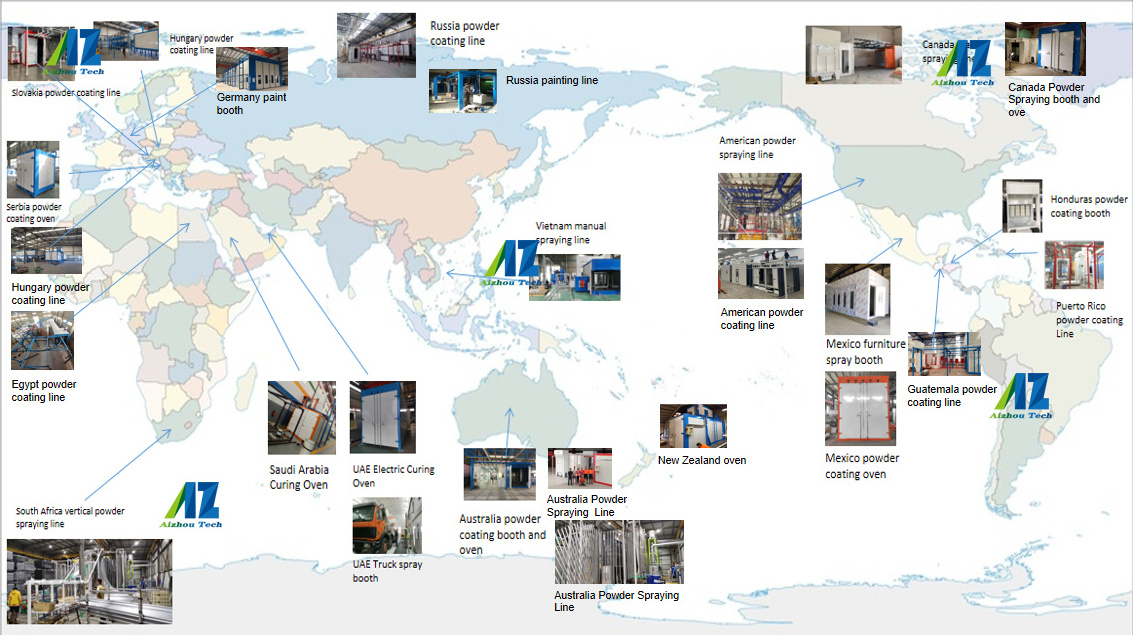

Our projects are worldwide

Our machines have been exported to dozens of countries and regions:

United States, Canada, Mexico, Chile, Brazil, Australia, New Zealand, Vietnam, Bangladesh, United Arab Emirates, Russia, Spain, South Africa,

etc 40 countries and regions.

Our Company

Shandong Aizhou Tech Co.,Ltd

Since 2011, Shandong Aizhou Tech Co.,Ltd has become leading manufacturer of powder coating field. Provide customers from Design—Production—Installation—Training and After-sales one-stop service.

From simple manual painting to fully automatic painting line, our project involves steel pipes, shelves, trolleys, radiators, fences, electric control cabinets, furniture, trucks, excavators, yachts and other industries;

Aizhou has provided excellent customized solutions for manufacturers, coating service providers, government projects and multinational companies in more than 40 countries and regions.

FAQ

1. Who are we?

10+ years specializing in the production of painting machines. Shandong Aizhou Tech Co.,Ltd has become a leading manufacturer of powder coating field. Our machines have been exported to dozens of countries and regions:

United States, Canada, Mexico, Chile, Brazil, Australia, New Zealand, Vietnam, Bangladesh, United Arab Emirates, Russia, Spain, South Africa,

etc. Provide customers from Design—Production—Installation—Training and After-sales one-stop service.

2. How can we guarantee quality?

We provide pre-assembly, and provide machine test report.

3.How long will it be delivered?

It will be packed and delivered within 20-25 workdays : by sea, air, express, etc.

4.Why choose us?

Project Design: More than ten senior and intermediate engineers design the best solution for you, and provide you with 2D and 3D drawings to display your project perfectly.

Visualization of production progress: We will update your production progress in a timely manner.

Quality control: Pre-assemble and check the product status before shipment, and provide you with equipment testing reports.

Installation: Our engineers will arrive at your site to provide installation, commissioning, training, and other services.

After sales: 24-hour video online technical support, 7 working days of engineer global arrival service.

Hot Searches