NaN / 0

Ailin Batch Type Powder Coating Plant Semi-Automatic Powder Paint Coating Line with Powder Coating Oven for Auto Metal Panel

Get Latest Price

US$ 22800

≥1 Pieces

US$ 21900

≥3 Pieces

Quick Details

Machine Type:

Powder Paint Oven, Drying Oven, Curing oven, Drying Oven, Curing oven, Powder Paint Oven

Place of Origin:

Zhejiang, China

Brand Name:

Ailin

Voltage:

110V/220V/380V/customized

Product Details

Product Description

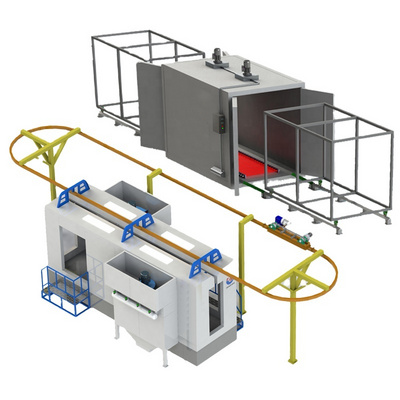

Compact Batch

Semi-Auto

Powder Coating Plant

If you have specific parameters and requirements for our powder coating oven, customization is available.

This Semi-auto powder coating line includes

1. a set of manual powder coating equipment

2. a pass-thru powder booth with filter recovery,

3. a gas curing oven with top tracks

4. a transport conveyor system

Suits for your limited factory space. Seeking for limited budget solutions.

Saves manpower that ensures productivity. Continuous batch production.

Saves manpower that ensures productivity. Continuous batch production.

Overhead Conveyor System

This overhead track system is easy to transport heavy materials into the oven.

Gas Burner Powder Coating Curing Oven

1. Engineered with top tracks to connect to powder coating line conveyor system, track numbers could be customized.

2. Famous burners takes full utilization of fuels to get required temperature in a shorter time.

3. Sandwich structured oven wall: 100mm thick rock wool board is inserted between galvanized inner wall and color-steel external skins for optimum insulation effect.

4. Powerful Circulation Fan circles hot air in the chamber to ensure even temperature distribution.

5. Controller provides accurate heating process, easy to set precise parameters, like temperature, heating time and control fan working.

|

Model

|

Curing Oven

|

|

worksize Dimensions

|

Customized

|

|

Wall Insulation

|

100% new rock wool board with 100 mm thickness

|

|

Power Supply

|

Gas/ LPG /Diesel / Electric

|

|

Voltage/Frequency

|

380V (50-60Hz) or as request

|

|

Warm-up Time

|

180° C (15-30min)

|

|

Temperature Stability

|

< ± 3-5°C

|

|

Temperature

|

Max.250° C

|

|

Circulation/ Air Flow

|

Vertical ,Variable through holes on the walls

|

|

Transportation

|

Trolley

|

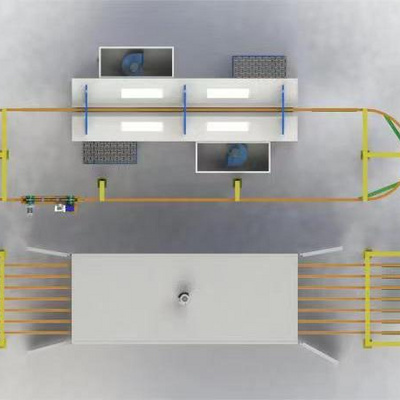

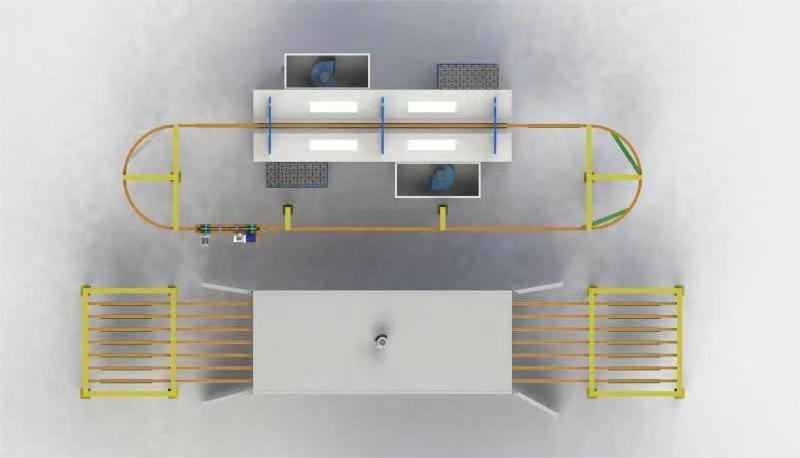

Tunnel powder coating booth

This conveyor powder coating booth is engineered with dual working station that supports to coat both sides simultaneously.

Top track of powder coating booth could be connected to the powder coating line conveyor to achieve continuous production, increases powder coating efficiency and ensures application quality. Control the working process and precisely set the interval of

filter cleaning.

|

Specification

|

|

|

|

Working Size

|

4600x2200x1800mm

|

|

|

Power Supply

|

Electric

|

|

|

Frequency

|

50HZ / 60HZ

|

|

|

Voltage

|

220 V - 380 V (customized)

|

|

|

Blower Powder

|

3.5 kw

|

|

|

Filters

|

8pcs

|

|

|

Filters Hang Type

|

easy for change

|

|

|

Filter Cleaning System

|

Pneumatic

|

|

AL-606 Powder Coating Machine

Helps You Do A Professional-Looking Powder Coating Job

1. Easy on-the-fly adjustment from 10-100KVs with a high voltage power supply designed for multiple coats and quick coverage on large/small objects

2. Innovative Fogging Nozzle

3. Hopper protects powder from the ambient and gently fluidizes it for an ideal powder delivery.

Our project in Uzbekistan

How to inquiry powder coating line?

Ailin coating has a professional and efficient working team.Our professional senior engineer to find the best solutions for you.You'd better offer the specifications of your workpiece to us.

The production process

(if you are new on coating, we will give you specialized suggestion of the whole work)

The size of the workpiece

(including the max length, width, height and weight)

The capacity

(how many pcs in 8 hours)

The available size of your factory (including the length, width and height)

The heating power(electricity, gas or diesel oil )

Automatic painting or manual painting pre-treatment process or not, if you do, automatic pretreatment,dipping pre-treaiment or sand blasting.

How many colors do you need to change every day.

The local electricity conditions(_v/_phase/_hz)

The any special requirements about the package.

Our powder coating system's design and production all according to customer's requirement(capacity, size of product, size of workshop).

|

Q1: Are you trading company or manufacturer ?

|

|

A: We are manufacturer which exported to many countries and we are specialized in producing powder coating equipment .

|

|

Q2:

What should I provide if interested in your powder coating equipment ?

|

|

A. The material/size(max)/weight(max)of your workpiece.

B. What's your daily output(one day=8 hours, one month=30 days)?

C. What heating power do you prefer: electric, gas, diesel?

D. The size of your factory(length, width and height)?

|

|

Q4: How to install equipment after purchasing your equipment?

|

|

A. We will provide installation information and installation videos

B. Our engineers will guide the installation and run the equipment.

C. After the debugging, will provide complete training and track customer device usage.

D. we can install overseas for you. But the engineers overseas installation cost, round trip air tickets, accommodation, meals and transport charges are on the buyers.

|

|

Q5: How is your company's after-sales service done?

|

|

A, Provide the list of consumables to assist customers in establishing a comprehensive equipment maintenance system.

B, After the equipment is delivered to the customer, our company will send professionals to track the customer equipment for 60 days.

C, Ifcustomer has a device failure in the process of using the device, our company will operate the device remotely through the computer network.

D,Any problems with the equipment, our company guarantees to give solutions within 12 hours.

|

Hot Searches