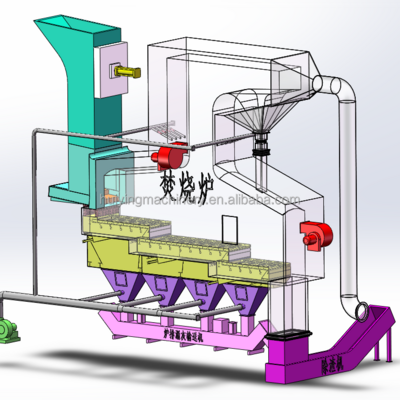

The garbage is sent to the hopper by the garbage crane or conveyor, piled above the feeder, and pushed into the furnace by the feeder regularly.

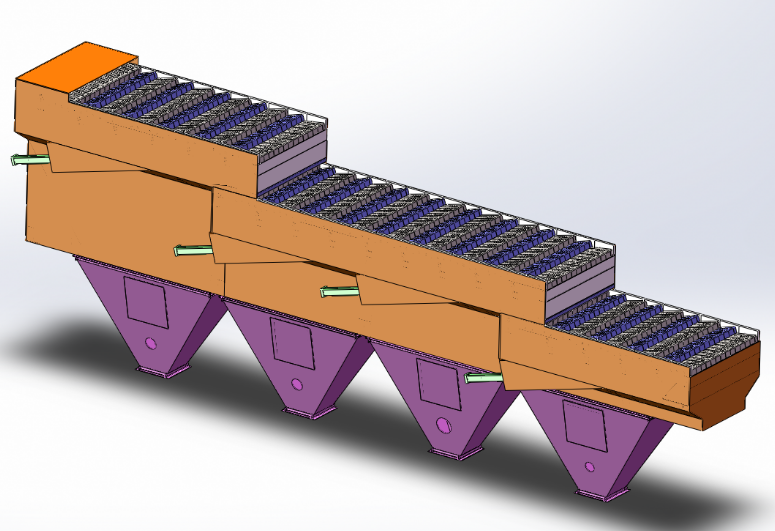

After the garbage into the furnace through three sections of the grate :

drying, burning, burning out , with a certain pressure and temperature,primary air is sent to the lower air chamber of the grate, through the grate surface air hole and grate gap through the garbage layer from bottom to top, to provide heat for the garbage drying, to provide oxygen for the garbage full combustion.

The ash produced by the complete combustion of the garbage enters the wet slagging machine through the slagging bucket and then enters the slag pit.

The horizontal ash leakage conveyor is connected under the air chamber, and a small amount of ash and slag under the grate is sent to the wet slag removal machine.

The flue gas produced by combustion enters the secondary combustion chamber through the throat, and the secondary air is added at the throat to adjust the furnace temperature, ensure the complete combustion of volatiles, and control the generation of nitrogen oxides.

The temperature of the secondary combustion chamber is between 850~1050℃, and the flue gas stays in the secondary combustion chamber for more than 2 seconds through the secondary combustion chamber exit into the waste heat utilization system,

And the user can consider the waste heat utilization methods such as hot water production, steam production and power generation according to the project scale and economic benefits.

The cooled flue gas after heat transfer is discharged by deacidification and dust removal.