NaN / 0

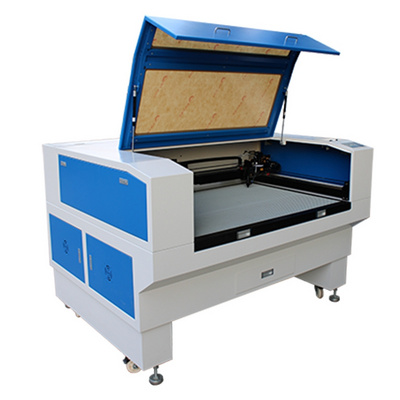

ARGUS laser cutter Auto Position 80W 100W Cnc Co2 Laser Cutting engraving Machine With Ccd Camera For Fabric Cloth

Get Latest Price

US$ 7000

≥1 Sets

US$ 6000

≥10 Sets

Quick Details

Laser Type:

CO2

Cutting Speed:

1000m/min

Cooling Mode:

WATER COOLING

Control System Brand:

RuiDa

Product Details

Main Categories

Product Description

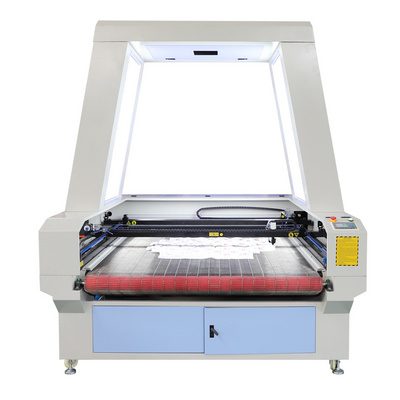

CCD Laser Cutter With Camera Solution

ARGUS’s superior quality fabric laser cutters are your easy answer to cutting your fabric quickly and accurately

New Large vision l

aser cutting machine , automates the process of cutting out dye sublimation printed pieces of fabri

c or textile both quickly and accurately, automatically compensating for any distortions or stretches that occur in unstable or stretchy textiles - exactly the type of fabrics that are used in sportswear

1. Can Replace 7-8 workers

2. Fabric Automatic Loading

3. Automatic Vision Recognition Software

4. Can cut without Artwork & Waitting

5. High accurate for different fabric cutting

6. No raw edge after cutting

Main Features

1) 30%~50% Faster than competition

2) Feeding and scanning at the same time, high efficiency , camera positioning and cutting speed 1000mm/s

3) Fully capable with auto feeding device for continuous high speed production to save labor cost

4) A conveyor bed and auto-feeder is used to keep cutting continuous, saving time and increasing production speed.

Product Application

Mainly used in clothing industry, fabric processing industry and curtain and sofa manufacturing industry, used for precise camera positioning and cutting of non-metal special-shaped patterns in many industries such as printing, clothing, leather, cloth toys, etc

Applicable material

A. Sportswear, jersey, cloth, banner, tent, inflatable model, advertisement, printing, hot air balloon, canvas, etc. (Mark Point)

B. Sportswear, uniforms, banner, shirts, toys, fabrics, shoe material (Visual scan model)

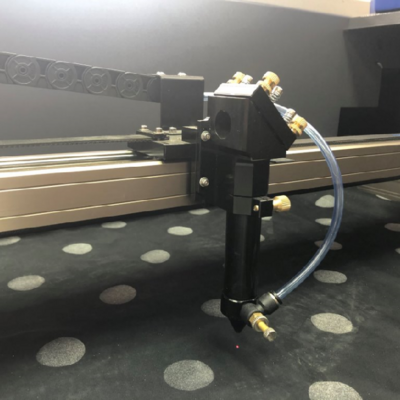

Laser Head

This type Laser Cutter adopts CCD camera positioning automatically,high cutting speed, unmatchable output quality

Sealed Glass Co2 Laser Tube

Sealed glass Co2 laser tube is one of the consumables for Co2 laser cutting machine. But the Made-In-China Co2 glass tube’s ROI is super high. our glass laser tube can reach 10000hours

LED Panel

A control panel with a coherent hot-key design and graphic icon displays that allow you to change the laser parameter setting directly

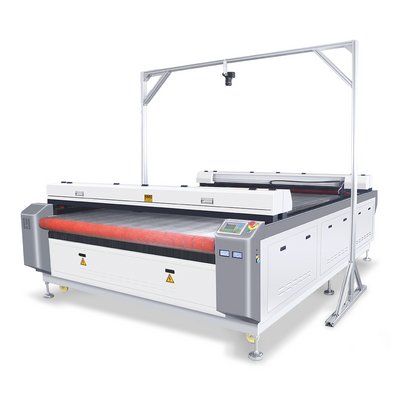

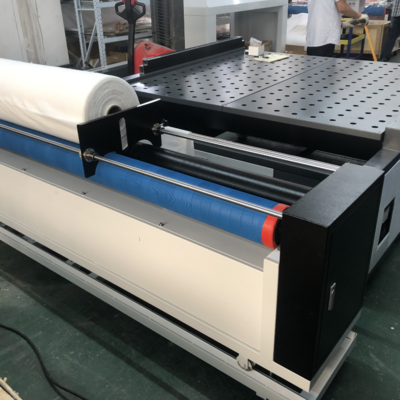

Auto Feeding Conveyor Table

SCU1610 is equipped with a conveyor belt, which can auto-feed the roll material after laser cutting. With the optional active feeder, the operator only needs to take care of the cut pattern pick-up job

Auto feeding bed

Auto-feeding system can load materials automatically which can save your labor force and cut the cost. This laser-cutting systems is especially suitable for the mass processing of textile and garment

Active Feeder

The piece goods in rolls are put on the rolling system,The table can move forward every time you finish cutting, and the rolling system can rotate the goods when working, the goods can be processed effectively

Active Feeder

Technical Parameter

|

SPECIFICATIONS FOR SCU1610 CO2 laser fabric cutting machine

|

|

|

|

|||

|

Working platform size

|

|

1600*1000 mm

|

|

|||

|

Laser Power

|

|

100w/130w/150w

|

|

|||

|

Controlling system

|

|

RUIDA

|

|

|||

|

Software

|

|

RDCAM

|

|

|||

|

Support format

|

|

PLT, BMP, DXF, DST, T100, etc

|

|

|||

|

Process Material

|

|

Non-metal Materials

|

|

|||

|

Max Cutting speed

|

|

500mm/s

|

|

|||

|

Engraving speed

|

|

2000mm/s

|

|

|||

|

Repeated accuracy

|

|

±0.2mm

|

|

|||

|

Min. cutting character

|

|

3mm

|

|

|||

|

Max. cutting depth

|

|

0-20mm(it's up to the material)

|

|

|||

|

Cooling ways

|

|

Circulation water cooling

|

|

|||

|

Working temperature

|

|

0-35°C

|

|

|||

|

Working humidity

|

|

5-95%

|

|

|||

|

Working Power

|

|

220V/50Hz/2.5kVA(Customize)

|

|

|||

|

Accessories

|

|

Air pump

|

|

|||

|

|

|

Exhausting Fan

|

|

|||

|

|

|

Air Cooling

|

|

|||

|

Dimension

|

|

2280*1600*1230mm

|

|

|||

|

Net weight

|

|

460KGS

|

|

|||

What kind of laser machine and model should I choose?

You can tell us your processing material, working size and detail requirement, detail work by picture or video so that we can judge whether our machine can meet your need.

What kind of materials does the laser machine can process?

We have different laser machines, such as Fiber laser, CO2 Laser, UV Las- er Green Laser. Normally Fiber laser can process metal and plastic. CO2 laser is for processing non metallic materials, such as Acrylic, PMMA,Wood, Glass, Leather, Jeans, Paper,Textiles Garments and so on. UV laser and green laser are also called cold laser source, they are usually used for plastic, glass,crystal and some special processing job.

Is it easy to operate?

We will send you manual and guide video in English, I can teach you how to operate the machine. lf you still can not learn how to use it, we can help you by Team viewer online help software. Or we can talk by phone email or other contact ways.

What s your guarantee. in case the machine breaks down?

The machine has one year guarantee. If it breaks down, generally speaking our technician will figure out what the problem may be,according to client's feedback. Parts except for consumable parts will be replaced for free if the problems are caused by quality fault.

Hot Searches