NaN / 0

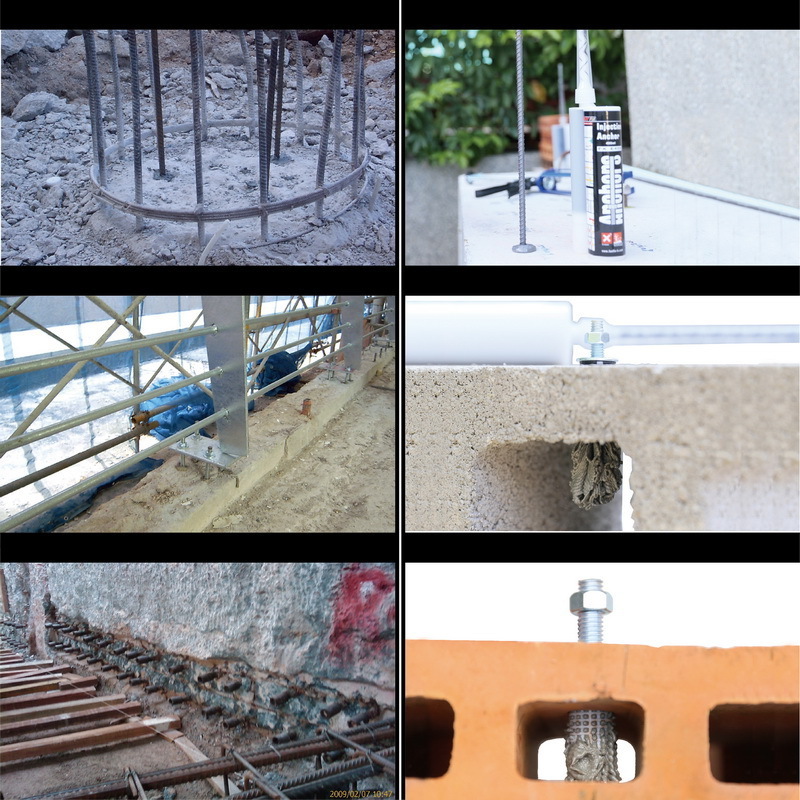

epoxy resin silicone gun construction spray foam chemical resistance concrete to steel adhesive

Get Latest Price

US$ 1

≥500 Pieces

Quick Details

CAS No.:

Mixture

Other Names:

Chemical anchor

MF:

Mixture

EINECS No.:

500-033-5

Product Details

epoxy resin silicone gun construction spray foam chemical resistance concrete to steel adhesive

Product Description

Product Name: Injection Cartridge (Epoxy acrylate styrene free resin)

Product Code: FX-V 360

Product Description: Solvent-free, epoxy based, two part high performance anchoring adhesive.

Uses: For the fixing of non-expanding anchors in the following:

u For structural work:

- Rebar / steel reinforcement anchoring in new and refurbishment works.

- Threaded rods

- Bolts and special fastening systems

u Mechanical and electrical services installation:

- Anchoring of supports for ducting and equipment.

u Metal Work, carpentry

- Fixing of handrails, balustrades and supports

- Fixing of railings

- Fixing of window and door frames

For fixing of the following substrates:

- Concrete

- Hard natural and reconstituted stone

- Solid rock

- Hollow and solid masonry

- Steel

- Wood

Product Details:

Application

1.

Drill hole to the diameter and depth required. The diameter must be in accordance with anchor size.

2.

The drill hole must be cleaned with air blower, starting from the bottom of the hole.

The drill hole must be thoroughly cleaned with steel brush. After brush, to use air blower to clean the drill hole again.

3.

Inject the adhesive into the hole, starting from the bottom, while slowly drawing back the static mixer. In any case avoid entrapping air. For deep holes extension tubing can be used.

4.

Insert the anchor with a rotary motion into the filled drill hole. Some adhesive must come out of the hole.

5.

During the resin hardening time the anchor must not be moved or loaded.

Technical Data

Gel and loading time:

| Application Temperature (℃) | Gel Time (min.) | Loading Time (min.) | |

| 35 | 2 | 20 | |

| 30 | 3 | 30 | |

| 20 | 5 | 60 | |

| 5 | 15 | 120 | |

| 0 | 30 | 180 | |

| -5 | 60 | 360 | |

Test Report:

| Test Item | Test Method | Test Result | |

| Density (g/cm 3 ) | ASTM D792-00 Method A | 1.58 | |

| Gel Time (min.) | ASTM D2471-99 | 180 | |

| Bond Strength (psi) | ASTM C882-99 | 1495 | |

| Water Absorption (%) | ASTM D570-98 | ||

| a. 100℃ / 1hr | 0.06 | ||

| b. 50℃ / 1hr | 0.32 | ||

| Compressive Strength (psi) | ASTM D695-02a | 8495 | |

| Tensile Strength (psi) | ASTM D638-03 | 1651 | |

| Elongation at Break (%) | 5.66 | ||

| Concrete compressive strength | Working standards | |||

| f'c = 4,000 psi (27.6 Mpa) | (mm) | |||

| Rebar size | Ultimate tensile load capacity (kgf) | Allowable tensile load capacity (kgf) | Hole diameter | Embedment depth |

| #3 (∅10) | 2908 | 817 | 13 | 90 |

| #4 (∅13) | 3890 | 1093 | 16 | 115 |

| #5 (∅16) | 7492 | 2104 | 20 | 125 |

| #6 (∅19) | 11727 | 3294 | 25 | 160 |

| #7 (∅22) | 16986 | 4771 | 28 | 190 |

| #8 (∅25) | 21560 | 6056 | 32 | 215 |

**For further information or MSDS/TDS request, please feel free to

CONTACT US

.

Packaging & Shipping

|

Product |

Volume |

Item Code |

Dispenser |

Case Q'ty |

Pallet Q'ty |

CTN Size (cm) |

|

Epoxy acrylate |

280ml |

FX-V280 |

FX-GUN 280 |

20 |

1400 |

31 x 21 x27 |

|

360ml |

FX-V360 |

FX-GUN 345 |

20 |

1200 |

35.8 x 25 x 28.5 |

|

|

380ml |

FX-V380 |

FX-GUN 380 |

20 |

1200 |

36.2 x 31.6 x 26 |

|

|

Pure epoxy |

280ml |

FX-E280 |

FX-GUN 280 |

20 |

1400 |

31 x 21 x 27 |

|

360ml |

FX-E360 |

FX-GUN 345s |

20 |

1200 |

35.8 x 25 x 28.5 |

|

|

400ml (3:1) |

FX-E400

|

FX-GUN400 |

20 |

1200 |

36 x 25 x 27.5 |

|

|

400ml (1:1) |

FX-QE400 |

FX-GUN400L |

20 |

1200 |

43.3 x 26 x 27 |

|

|

650ml |

FX-QE650 |

FX-GUN620 |

10 |

850 |

28 x 23 x 30 |

|

|

Polyester |

360ml |

FX-HP360 |

FX-GUN 345 |

20 |

1200 |

35.8 x 25 x 28.5 |

|

380ml |

FX-HP380 |

FX-GUN 380 |

20 |

1200 |

36.2x31.6x26 |

**If any questions about package, please feel free to CONTACT US .

Shipping:

By sea/ air/ courier. (FOB Kaohsiung)

Courier includes DHL, FedEx, TNT, EMS, etc.

Hot Searches