NaN / 0

geosynthetic clay liner price bentonite clay liner geosynthetic liners

Get Latest Price

US$ 1.18

≥1500 Square meters

US$ 1.02

≥8000 Square meters

US$ 0.94

≥35000 Square meters

Quick Details

Warranty:

More than 5 years

After-sale Service:

Online technical support

Project Solution Capability:

total solution for projects

Application:

Lanfill, Landfill waterproof

Product Details

Product Description

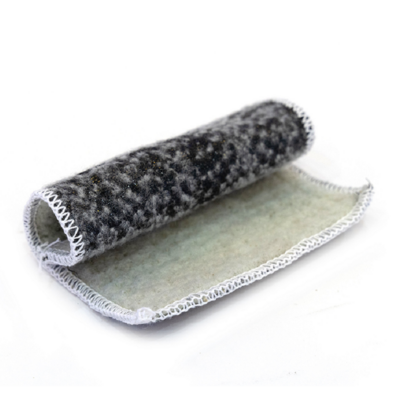

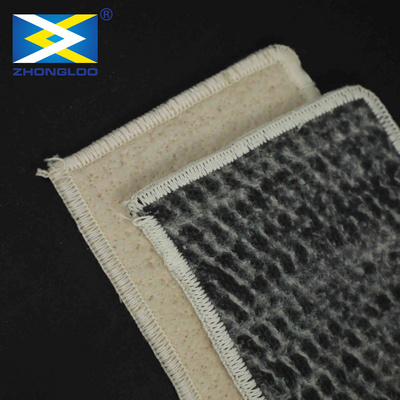

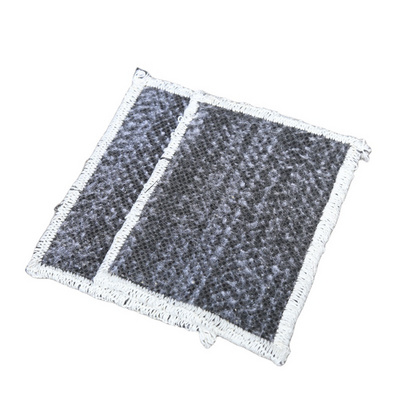

GCL sodium bentonite clay liner is a blanket-shaped waterproof material made of sodium bentonite as the main raw material by acupuncture, acupuncture lamination or adhesive method, with geotextiles on both sides and sodium bentonite in the middle. Sodium-based bentonite clay liner is also known as gcl. According to the production method, it is divided into needle punched sodium-based bentonite clay liner (GCL-NP), needle punched-membrane coated sodium-bentonite clay liner (GCL-OF) and base adhensive bentonite clay liner(GCL-AH). According to the variety of bentonite, it is divided into artificial sodium bentonite (A) and natural nano-bentonite (N)

Lianxiang brand GCL belongs to GCL-NP and GCL-OF. Bentonite choose natural kind.

GCL-NP GCL-OF

Details see the difference

1. Whether can ensure the textile on top and bottom layer smoothly spreaded is the first important step to guarantee the quality of GCL. As if there occured any folded place, the bentonite powder will not spilled evenly on the textile, thus will cause potential leakage during installation. Lianxiang knows the importance of this first step and made a lot of improvement to guarantee the quality.

2. The unrolling speed of top and bottom layer textile must keep in pace, otherwise will casuse the textile stretched too much and make the tensile strength of the GCL lower than standard. And result in the GCL easy broken during installation.

3. After long-term research by our technique team, we found irregular needle punch can greatly improve the peel strength of GCL than regularly punched. Besides, the wave shape of surface also helps to improve the peel strength.

The needles choosing barbed needles, so when the needle punch through the GCL from top non woven geotextile layer to the bottom woven geotextile(black color) layer, it will bring some non woven textile fibers together punch through(see picture below). And using thermal method to let these fibers with woven fabric stick together, and this again, will improve the peel strength.

Features

The mineralogy name of bentonite is montmorillonite, and natural bentonite is mainly divided into two categories: sodium base and calcium base according to chemical composition. Bentonite has the property of swelling when it encounters water. Generally, when calcium-based bentonite swells, its expansion is only about 3 times its own volume, while sodium-based bentonite absorbs water five times its own weight when it meets water, and its volume expands to 15-17 times its original volume.Besides, the sodium-based bentonite is locked between two layers of geosynthetics to protect and strengthen the GCL, so that the GCL has a certain overall shear strength.

1. Compactness: Sodium-based bentonite forms a high-density diaphragm(like a door) under hydraulic pressure. When the thickness is about 3mm, its water permeability is below 1×10(-11m)/sec, which is equivalent to 100 times the compactness of normal clay with a thickness of 30cm. .

2. GCL has permanent waterproof performance: Because sodium bentonite is a natural inorganic material, even after a long time or changes in surrounding environment, it will not age or corrode, so the waterproof performance is durable.

3. Easy to install and shortting construction period: Compared with other waterproof materials, the construction is relatively simple and does not require heating and pasting. Simply connect and secure with bentonite powder and nails, washers, etc. No special inspection is required after construction, and it is easy to repair if waterproof defects are found. GCL has the shortest construction period among existing waterproof materials.

4. Hardly affected by temperature: it will not be brittle in cold climates.

5. Integration of waterproof materials and objects: When sodium-based bentonite meets water, it has an expansion capacity of 20-28 times. Even if the concrete structure vibrates and settles, the bentonite in GCL can also repair cracks on the concrete surface within 2mm.

6. Greenning and environmental protection: bentonite is a natural inorganic material, which is harmless and non-toxic to the human body, has no special impact on the environment, and has good environmental protection performance.

Technique Data Sheet(TDS)

Beside the GCL, we supply a

Hot Searches