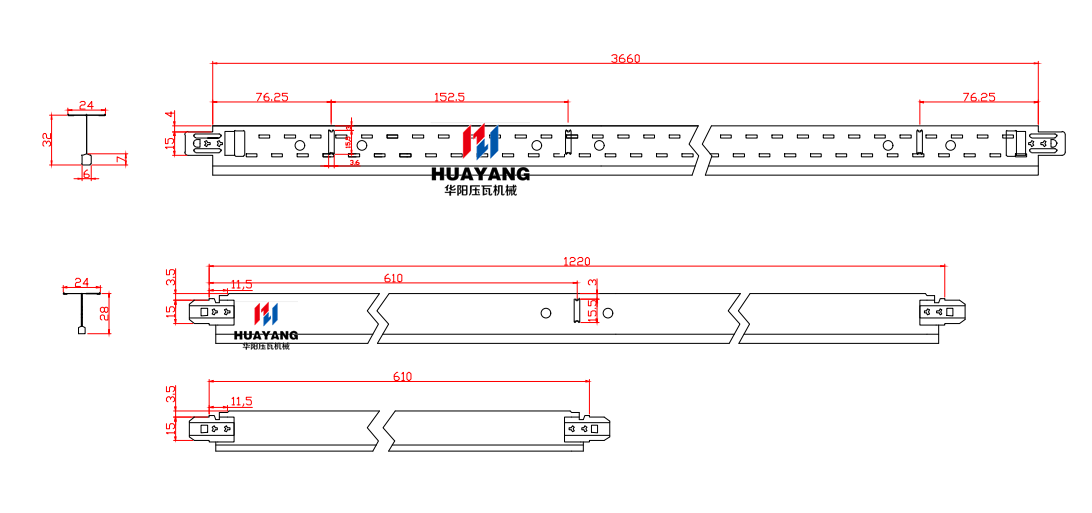

roll forming roller stations :20 sets

Straightening rollers:1 set

The roll forming part with Emergency stop device .Hardness:HRC55(The surface is smooth and does not scratch the product.)

Roller Model Material: Cr12MoV,Quenching hardnesHRC55,electric processing

Roller diameter:39mm

Roll forming speed:30m/min(including the punching)