NaN / 0

disposable take away food container foam food box making machine

Get Latest Price

US$ 110000

≥1 Sets

Quick Details

Max.Forming Height(mm):

80 mm

Forming Width (mm):

1100 mm

Forming Length (mm):

1450 mm

Heating Power (kW):

180 kW

Product Details

Product Description

Two Months Promotion Cheap and Durable Full auto disposable thermocol plate making machine

Product Application

PS disposable foam food container/plate/dish/tray/bowl/box making machine , which can form lunch box from raw material. The material is recycled. The work flow is as follows: raw material---(PS foam sheet extrusion line)---foam sheet---(lunch box forming machine and cutting machine)---lunch box---(plastic recycle machine)---plastic granulars( this part can be used as raw material)----foam sheet.

|

Machine name

|

capacity

|

Machine name

|

Forming Area mm

|

Forming speed times/min

|

|

ps foam sheet extruder

|

2tons/day

|

vacuum forming machine

|

600*1000

|

10-12

|

|

|

4tons/day

|

|

1100*1200

|

10-12

|

|

|

6tons/day

|

|

1100*1450

|

18-20

|

Certifications

Detailed Images

1. PS foam sheet extruder machine

PS foam sheet extruder machine uses a tandem screw technology to produce fine-block cell-structured extruded polystyrene foam sheet with high strength and a pearl and even surface, in a continuous roll, from polystyrene injection an eco-friendly blowing gas and additives. It has a user friendly operating system with inverter controlled driving, digital temperature control and so on.It produce PS foam sheet, which is a kind of new-type packing with the features of shock proofing, sound insulating, heat preservation, damp proof, safety, and good plasticity. It is used widely in the packing of food, fruit, electronic product, daily necessities, hardware product, advertisement plate, etc.

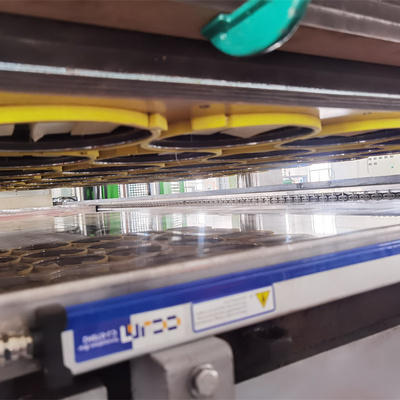

2.Fully Automatic Robot Arm Vacuum Forming Cutting And Stacking Machine

PS disposable foam food container/plate/dish/tray/bowl/box making machine makes different kinds type of fast food box, foam tray, foam plate, foam container and so on.

The biggest advantage is forming cutting stacking and on-line crusher integration, reduce work link, produce the product directly, it can be collected in stacking area of work to save time, save the production base and greatly reduces the working intensity save artificially.

Forming Area: 1100mm*1400mm.

Forming Speed: stable 18cycles/min.

Edge waste will be crushed and collected directly to bag or transfer to special recycle room, keep the forming workshop clean and tidy,save manpower to carry the leftover material.

The stacking part use double robot arms design . The servo motor control the mechanical arms reciprocating motion, the mechanical arms catch the plate by vacuum sucker, it use conveyer belt to collect the plate from both sides, it can stack 25 pcs plate for single row, it is convenient to put in the carton box or bag. This part fix two sets static eliminators, it can remove static, and avoid fire

Suck and pull the food containers up. Even the containers don't sucked out successfully, this won't affect next move.

Two stations feeder

Double feeding shaft alternately, can put two sheet rolls on, save time increase effiency.

Three sections heating

Total heating length 4.4m, relatively extend heating time, avoiding over high temperature melt the sheet, at the same time making better secondary foaming effect.

120T Cutting Force

Hydraulic cylinder is 220mm, contact area increase 1 time, the pressure on unit area decreases, so that extend cycliner, hydraulic circuit and solenoid valve life.

The board use high quality stainless steel, dense and thickness grid design make sure durable life long time.

Steel chain rail and double thicker chain

Other factory use Aluninum rail, we are the only factory use steel rail, much longer lifetime and save chiller for customer. Steel rail is more durable don't request chiller, cooling tower is fine.

3. PS scrap recycling and pelletizing machine .

This recycling and pelletizing machine is designed to reclaim the foamed polystyrene and polyethylene materials almost identically to new ones with its own superior filtering performance.

Detail Photo of PS foam food containers

Our Service

Related Products

Our Company

Factory History

Founded in 1994, start with making PE foam net machine and fruit grading machine, during twenty five years of development, now has developed CE certified PS foam food container production line, Robot Arm Vacuum Forming Machine, EPE foam equipment, Fruits Cleaning, Waxing & Grading Machine, PE Cap Liner Foam Sheet Extrusion Line, PE/PS Recycling machine, totally more than 20 kinds of machines.

Traffic

We are located in Longkou City, Shandong Province, China. The traffic is very convenient, it is only 45mins far from Yantai Penglai International Airport by car, and 1.5h from Yantai High-speed rail station. And adjacent to the Qingdao seaport.

Fabricating Machinery

Fabricating machinery is the lifeblood of a production factory. We continues to introduce high-end processing equipment, performs near-perfect processing in accordance with its highly advantageous production process, and uses cutting-edge inspection equipment to perform rigorous inspections in all directions and in the entire process, ensuring product quality. The quality of reliability reflects the international level of the product.

Hot Searches