NaN / 0

Hot Melt Glue For Baby Diaper adhesive Dispenser Fabric Hot Melt Glue Coating Machine Glue Paper Hot Melt adhesive For Edge

Get Latest Price

US$ 4.5

≥25 Kilograms

Quick Details

CAS No.:

no

Other Names:

HMA

MF:

no

EINECS No.:

no

Product Details

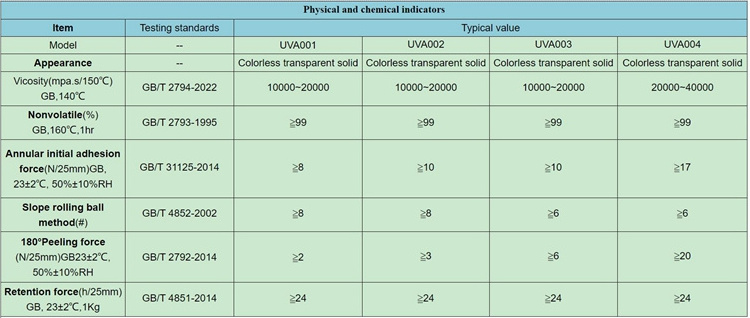

Uva-cured acrylic hot melt pressure sensitive adhesive

Product Description

|

Product Series |

|

|||||||||||||||||||||||||||||||

|

Composition |

|

|||||||||||||||||||||||||||||||

|

Properties |

|

|||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||

|

Notes on coating |

4.1 This adhesive cannot be mixed with other adhesives. Before use, clean the container, glue pump, glue delivery pipe, and coating head. 4.2 This product is a UV cured hot melt pressure-sensitive adhesive, which is a solid state at room temperature. Care should be taken to avoid light during transportation and storage. 4.3 Glue thickness: Apply according to customer requirements. 4 .4 This adhesive is mainly used as a protective film adhesive and can be used for the coating of low weight pressure sensitive adhesive.

Remark : The substrate for this test is a thickness of 50 μ The PET of m is coated directly; This data is for reference only, and specific data needs to be measured according to customer needs . 1 The curing of UV hot melt adhesive is closely related to the UV lamp energy and coating speed. The substrate used for coating is different, and the energy and speed also need to be adjusted accordingly. 2 Heat the pressure plate glue machine to around 150 ± 10 °C and insert it into the glue box to prepare for coating. 3 Temperature requirements for coating head: specific adjustments will be made based on equipment and process conditions. 4 Coating speed: Adjust according to the adhesive thickness and UV lamp energy. |

|||||||||||||||||||||||||||||||

|

Adhesion |

|

|||||||||||||||||||||||||||||||

|

Ripening of tape |

In order to make the performance of the adhesive reach a stable value, and at the same time make the cohesive strength of the glue close to the maximum value, the coated tape must be stored for 24 hours before testing, processing or use |

|||||||||||||||||||||||||||||||

|

Storage and transportation |

l The validity period of this product is six months, and the storage temperature is 25±5°C in a ventilated, dry and cool place, avoiding light. l Can be transported as non-dangerous goods |

|||||||||||||||||||||||||||||||

Hot Searches