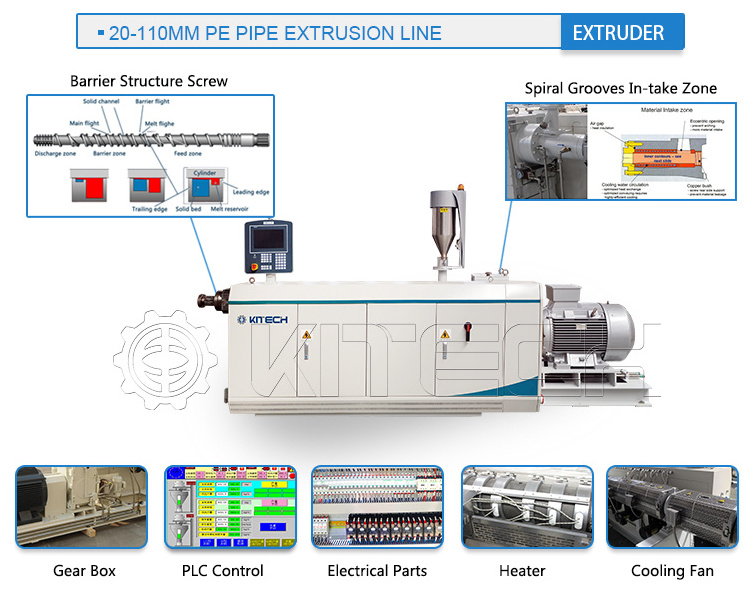

L/D: 33:1

Capacity: 220kgs/h

Motor power: 55KW

Output/Energy: 4.2kg/kW

Or

Model:

HSJ60/38

L/D: 38:1

Capacity: 380kgs/h

Motor power: 90kW

Output/Energy: 4.2kg/kW