NaN / 0

Industrial matcha powder impact mill tea leaves air classifier mill spices micronizer herb pulverizer machine

Get Latest Price

US$ 26500

≥1 Sets

Quick Details

Output (kg/h):

400 - 2000 kg/h

Feeding Size (mm):

1 - 15 mm

Output Size (mesh):

2 - 180 mesh

Power (kW):

55

Product Details

Products Description

BRAVO CJ Superfine impact mill is developed and optimized based on the similar domestic and foreign products with our practical experience,the multifunction equipment is very suitable for grinding,classifying,shaping and depolymerizing the materials with Mohs’ hardness below 4 degree.

Can be connected with air classifier consisting of production line for protein separating and extracting from agricultural product,for example:pea protein,wheat protein.

Heat-sensitive,inflammable and explosive materials can be ground with inert gases, which can be cycle use.

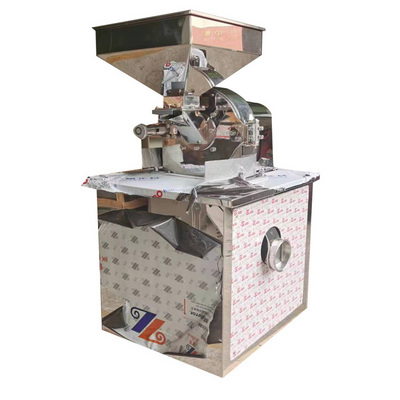

Material feed into the grinding chamber by a dosing feeder,they are impacted,sheared and ground by high speed rotating unit and stator equipped with grinding tooth,the powdered material enters into the classifying area,under the action of centrifugal force from classifying wheel inside of impact mill and draught fan,the qualified powder is collected by the cyclone and bag filter,the oversize powder is continued to grinding.

Technical Features

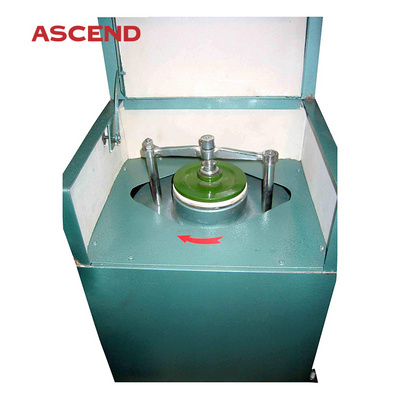

1.This machine is a horizontal-shaft reflective mill, which can complete the two processing procedures of fine grinding and powder sorting at the same time. The mill is composed of a movable disk and a ring gear, which rotates at a high speed through a special shaped movable disk. It is repeatedly squeezed, collided, and sheared between the movable disk and the static gear ring to achieve crushing.

The material is transported into the crushing cavity by the quantitative feeding system, and the crushed material is driven by the airflow into the classification area. Qualified materials are collected by cyclones and dust collectors, and unqualified materials are returned to the grinding area for grinding.

2.The machine has compact and reasonable structure, small size, low energy consumption, high efficiency, stable rotation, low noise, reliable sealing, no dust pollution, simple installation, easy disassembly and repair, and convenient replacement of damaged parts

3. The equipment adopts the advantages of domestic and foreign dry-process mechanical pulverizers, and can be cooled by large air volume or water jacket according to needs to reduce the heat of smashing and prevent the defects of material particles sticking to the wall and sticking to the crushing disk surface.

4.The crushing and grading integrated machine can dispense the materials that meet the fineness requirements in time to avoid over crushing and narrow the particle size distribution of the materials.

5. It is suitable for processing a variety of materials in various industries, and the particle size can be adjusted arbitrarily without stopping the machine. Product granularity is uniform.

6. This machine is widely used, suitable for dry materials with Mohs hardness less than 5 and water content less than 20% can be crushed by this machine.

7.For agglomerated materials, it has a good dispersing function, with automatic slag discharge, and the materials that are not easily crushed can be automatically separated and discharged.

FAQ

Q: What information should be provided to get a quotation?

A: Each air classifying mill is specially designed for each customer according to specific material, capacity, feed material size and product size. Before we can work out a detailed proposal or quotation, we have to know the following information:

1) Detailed information of material that you want to mill.

2) Size of your feeding material

3) Particle size after ground

4) Input capacity in kg/h

Q: How the machine will be delivered ?

A: The system is usually dismantled into grinding chamber, cyclone, bag house, draft fan and control cabinet for shipping. Each part is packed in box made by plywood.

Q: What kind of after sale service you can provide?

A: We have professional after sale service team who

can reach you in short notice. They can supervise the installation, do commissioning and train your workers.

can reach you in short notice. They can supervise the installation, do commissioning and train your workers.

Q: What standard models do you have?

A: We have the following standard models

Technical Parameters

|

Model

|

CJ-60

|

CJ-80

|

CJ-100

|

CJ-120

|

CJ-140

|

|

Capacity (kg/h)

|

100-1200

|

400-2000

|

500-4000

|

800-6000

|

1200-10000

|

|

Input size (mm)

|

≤15

|

≤15

|

≤15

|

≤15

|

≤15

|

|

Output size (μm)

|

2-180

|

2-180

|

2-180

|

2-180

|

2-180

|

|

Total installation power (KW)

|

22-45

|

45-55

|

75-90

|

110-160

|

200-250

|

Product Application

CJ series air classifying mill is used for fine and ultra-fine grinding of soft to medium hard, brittle, crystalline and fatty materials with a controlled particle size distribution;

Spices

Herb chips

Matcha powder

Sawdust

Carbon black powder

Kaolin clay

Packing & Shipping

Hot Searches