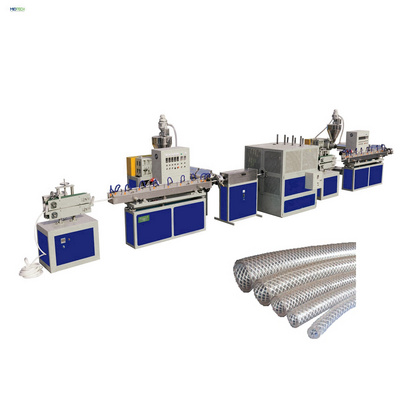

Material of screw: 38CrMoAl

Heating zones: 4

Heating power: 35kw

Cooling mode: Air fans

Driving motor: 55KW (siemens)

Dosing feeding motor: 1.5KW

Vacuum pump: 1 set

Cool mode: Air fans: 3 Sets