NaN / 0

Fully automatic chicken embryo vaccination machine for vaccines

Get Latest Price

US$ 100000

≥1 Pieces

US$ 99000

≥3 Pieces

US$ 98000

≥5 Pieces

Quick Details

Weight (KG):

1200

Place of Origin:

Guangdong, China

Brand Name:

WANBO

Model Number:

V150

Product Details

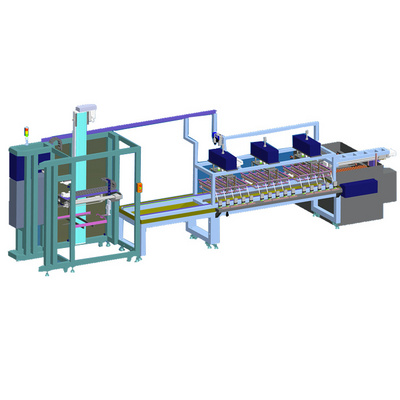

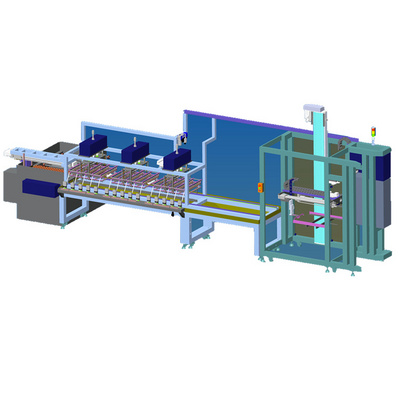

Fully automatic chicken embryo vaccination machine for vaccines

Fully automatic chicken embryo vaccination machine for vaccines

Model: 36 eggs, 42 eggs, 72 eggs, 150 eggs

The automatic chicken embryo vaccination machine is a professional equipment for producing influenza vaccines and bird flu vaccines. Using the chicken embryo vaccination machine to replace manual vaccination operations can quickly improve the quality and output of influenza vaccines and bird flu vaccines.

2. Product features

In the production of traditional embryotoxin vaccines, all manual operations are used, which results in low production efficiency, high labor intensity, and difficulty in ensuring the uniformity of product quality.

This equipment completely changes the traditional production process in the production of embryotoxic inactivated vaccine due to the use of automated equipment, making the process simple, reducing the floor area, increasing the production capacity by 4 times under the same production area, and saving air-conditioning energy. , there is no need to set up a level 100 area in the production area. Since the equipment connects different production areas, it automatically transfers chicken embryos from one area to another, saving a lot of manpower. Since the processing of chicken embryos is all completed by equipment, pollution is reduced, product quality is improved, and product quality uniformity is achieved.

|

|

Features |

describe |

|

1 |

Automation of the entire vaccination process |

It is highly intelligent and can automatically complete egg disinfection, sterile air drying, punching, poison injection, injection needle disinfection and other processes. The entire process is controlled by a programmable controller. Due to the small pinhole, chicken embryos do not need to be waxed. The equipment can process 15,000-16,000 chicken embryos per hour. |

|

2 |

process sterile environment |

The entire process is carried out under a 100-level laminar flow hood to ensure that the project is aseptic. |

|

3 |

save human effort |

Only 3 people are required to complete the equipment operation, and the labor intensity is greatly reduced. One person feeds the eggs into the machine, one person receives the eggs, and another person feeds the eggs into the incubator. Usually the work tasks of about 20 people can be completed. |

|

4 |

Improve chicken embryo unit yield and titer |

Product quality uniformity is good. Practice has shown that the unit yield of chicken embryo allantoic fluid has been improved compared with artificial inoculation, the titer has been significantly increased, and the waste embryo rate has been significantly reduced. The waste embryo rate is 4-6 percentage points lower than manual injection. The injection dose error does not exceed 4%. |

|

5 |

easy to use |

The needle can be installed and disassembled as a whole and put into a special stainless steel box for sterilization. After the venom bottle is placed in the rack and tightened, the inoculation operation can be carried out. After the work is completed, use prepared sterile water to clean in place. During the operation of the equipment, the amount of poison injected can be detected at any time to ensure the accuracy of the poison injection work. When air pressure fluctuations occur, the device automatically gives an alarm and takes necessary protective measures. |

|

6 |

Small footprint |

Length X Width X Height = 2.4 meters X 0.6 meters X 2 meters |

|

7 |

All accessories are localized |

The egg tray uses a standard domestic 150-hole egg tray. The poison injection needles, hoses and other consumables are all made of materials sold on the market and do not need to be purchased by the manufacturer. |

|

8 |

consume |

The power consumption is about 1500W. Use oil-free, water-free 0.4MPa compressed air. |

|

9 |

Comply with GMP requirements |

The fuselage is entirely made of 304 stainless steel parts, and key components are made of 316L stainless steel. The appearance of the equipment is smooth and there are no dirt spots. Easy to repair and maintain. High-efficiency filters are used to supply air in the work area, and the wind speed is greater than 0.25 meters per second. |

|

10 |

Embryovirus vaccine production line operation |

Combined with the use of chicken embryo egg detection machine, allantoic fluid harvester, and waste embryo processing machine, the production line operation of embryotoxin vaccine can be realized. The entire production process is automated, the battlefield area is small, operators are saved, product quality is improved, and pollution losses are reduced. |

Equipment specifications: standard egg trays 36 pieces, 42 pieces, 72 pieces, 150 pieces

Hot Searches