NaN / 0

Factory electric heating and mixing tank for homogenizer mixer cosmetics liquid soap making machine

Get Latest Price

US$ 5200

≥1 Sets

US$ 3800

≥5 Sets

Quick Details

Barrel Volume (L):

200(Please send us your enquiry for details)

Max. Loading Volume (L):

5000 L

Range of Spindle Speed(r.p.m):

1 - 3800 r.p.m

Max. Loading Capacity:

5000

Product Details

Product Description

Introduction

Steam heating style hand sanitizer liquid soap shampoo blending machine is our latest product research and developed by our company which combined overseas superior emulsifier experience with domestic cosmetic enterprise feedback. This machine adopts imported stainless steel, scientific homogenizing system, reasonable scraper blending to ensure equivalent homogenizing and make product more smooth, even and bright.

Feature

1, Detergent body wash shower gel shower cream liquid soap shampoo mixing making machine equipment consists of cabinet and blending tank.

2, There is advanced scraper blending machine, with the working of electricity, the PTPE (F4) composite plate touch the boiler correctly and solve the problem of sticking materials. The ideal stepless speed adjustment device, can adjust rotation within 0-60rpm willingly.

3, advanced homogenizing system imported from USA ROSS Company, the homogenizer is in the bottom to ensure homogenizing material even with small productivity. The sealing adopts recycled water cooling system and can work long time, conquer homogenizing problem regarding to high viscosity materials. A frequency conversion speed adjustment controller to satisfy kinds of complicate ingredients (Emulsifying capacity 3 times per minute) upper homogenizer as option to work with upper homogenizing and emulsifying so that the material emulsifying effect is better; product is more bright and luminous.

Usage

Detergent body wash shower gel shower cream liquid soap shampoo mixing making machine,Automatic Electric Heating Detergent Mixing Machine,Shampoo Blending Tank is mainly suitable for preparation of liquid detergents(such as cleanser essence,shampoo and shower cream etc)Integrating blending, dispersing ,heating and cooling etc. functions,the reacting machine is an ideal device for liquid perparation in various factories .

Feature

1, Detergent body wash shower gel shower cream liquid soap shampoo mixing making machine equipment consists of cabinet and blending tank.

2, There is advanced scraper blending machine, with the working of electricity, the PTPE (F4) composite plate touch the boiler correctly and solve the problem of sticking materials. The ideal stepless speed adjustment device, can adjust rotation within 0-60rpm willingly.

3, advanced homogenizing system imported from USA ROSS Company, the homogenizer is in the bottom to ensure homogenizing material even with small productivity. The sealing adopts recycled water cooling system and can work long time, conquer homogenizing problem regarding to high viscosity materials. A frequency conversion speed adjustment controller to satisfy kinds of complicate ingredients (Emulsifying capacity 3 times per minute) upper homogenizer as option to work with upper homogenizing and emulsifying so that the material emulsifying effect is better; product is more bright and luminous.

Usage

Detergent body wash shower gel shower cream liquid soap shampoo mixing making machine,Automatic Electric Heating Detergent Mixing Machine,Shampoo Blending Tank is mainly suitable for preparation of liquid detergents(such as cleanser essence,shampoo and shower cream etc)Integrating blending, dispersing ,heating and cooling etc. functions,the reacting machine is an ideal device for liquid perparation in various factories .

|

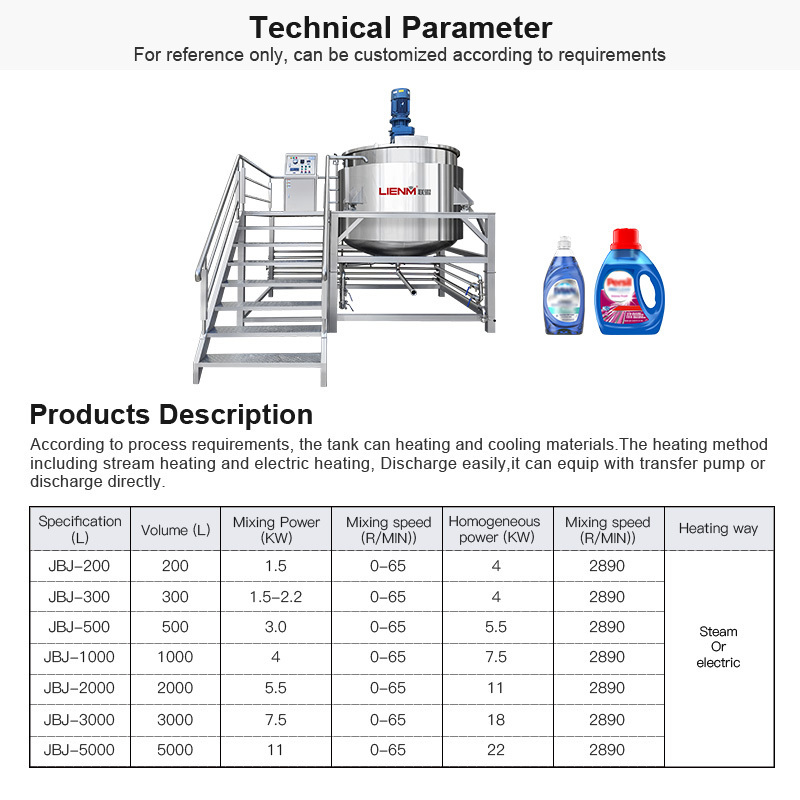

Technical Parameter

|

|

|

|

Capacity:

|

50-5000L (Can be Customized)

|

|

|

Mixing Power

|

0.75-15KW

|

|

|

Mixing Speed:

|

0-60 (R/MIN)

|

|

|

Homogenizing power

|

2.2-22 KW

|

|

|

Homogenizing speed

|

0-3880 (R/MIN)

|

|

|

Heating Mode:

|

Steam heating or electric heating (optional)

|

|

|

production

|

shampoo,liquid soap etc.

|

|

|

contact material

|

SUS304/SS316L

|

|

Other types

Recommend Products

Company profile

Why Choose Us

Our factory

We have 2 factories, one was built in the year of 1983 at Jiangsu province, mainly produce mixing tanks.vacuum emulsiher and storage tanks, with 30 acres space and with pressure tank certifcate. Another wasbuilt in the year of 1996, mainly produce RO water purifer, flling packing lines, is with 5000 square meters

O

ur technology

2.1- We have 10 R & D experts, we design new machines every year and our experts study abroad everyyear, they are core of our company2.2- Our R & D is equip with file management system, we recorded programs for every customer

Our service

3.1- We can customize the machines according to customers demands;3.2- we can help customer to handle the whole process of producing daily cosmetic, from raw material,packages,decoration machines ETC:3.3- We have 10 engineers, they can fly to foreign countries to fix and install machines3.4- Our response is very fast, our sales team work dav and nicht, if you have anv guestions about themachines, they will reply you soon and give solution within 8 hours.3.5- Can help the formulation, packages and raw material problem3.6- Can test machine before place order

Our machines

4.1- Adopt high technology4.2- SS material is from china No 1 quality company4.3- Adopt famous brand of spare parts, such as Siemens, Schneider, ABBOmron.Panasonic ETC4.4- Working stable