NaN / 0

road line paint highway traffic coating powder Hot Melt road marking paint

Get Latest Price

US$ 378

≥3 Tons

US$ 350

≥4 Tons

US$ 286

≥100 Tons

Quick Details

CAS No.:

64742-16-1

Other Names:

powder coating

MF:

Mixture

EINECS No.:

64742-16-1

Product Details

Product Description

|

Application

|

Mark on the Road with effects of guidance and Warn

|

|

Brand

|

LUHU

|

|

Type

|

Normal Thermoplastic

|

|

Ingredient

|

C5 Petropols, EVA, PE wax, titanium dioxide, filler materials

|

|

Appearance

|

Powder

|

|

Color

|

White & Yellow (OEM)

|

|

Weight

|

25kg/bag

|

|

Heating Temperature

|

180-200°C

|

|

Touch/ Full Dry Time After Marking

|

3/10 mins

|

|

Shelf Life

|

12 months

|

|

Features

|

1.Strong Adhension Power and Durability

2.High Dirty Pick-up Resistance

3.Save Cost of Gas and High Usage Ratio

4.Not Fade Easily

|

Application description

Hot melt reflective marking paint is mainly used for more than 2 level of the highway and highway, the marking coating thickness of this paint is (1.0 ~ 2.5) mm, the paint is mixed with reflective glass beads, and in the marking construction, the surface of the reflective glass beads. This marking has good night reflective performance, long service life, according to the traffic flow of large highway construction of all kinds of road marking paint demand estimates, small and the quality of the paint itself, generally up to (2 ~ 3) years. The construction of hot melt coating requires special heating equipment. For the second recoating of the old marking line, the thicker old coating should be removed before coating.

Construction mode

Hot melt marking paint is solid powder at room temperature. During construction, the paint is put into the melting kettle, and the temperature in the kettle is controlled between 180 ° C and 210 ° C. While melting, it is stirred, and after melting, it is put into the insulation melting hopper of the marking car. Melt coating then back into the marking bucket, and heat preservation to keep the material molten state. Before the line is marked by the pre-marking machine position, according to the design drawing indicated on the coating position with the lower coating machine primer. The marking coating can be applied only after the coating agent dries thoroughly. When the scribing begins, the scribing bucket should be placed on the road, because there is a certain gap between the scribing bucket and the ground, when the scribing car ahead, by automatic flow and scrape out a neat line. The glass bead spreader can automatically and evenly spread a layer of reflective glass beads on the marking line.

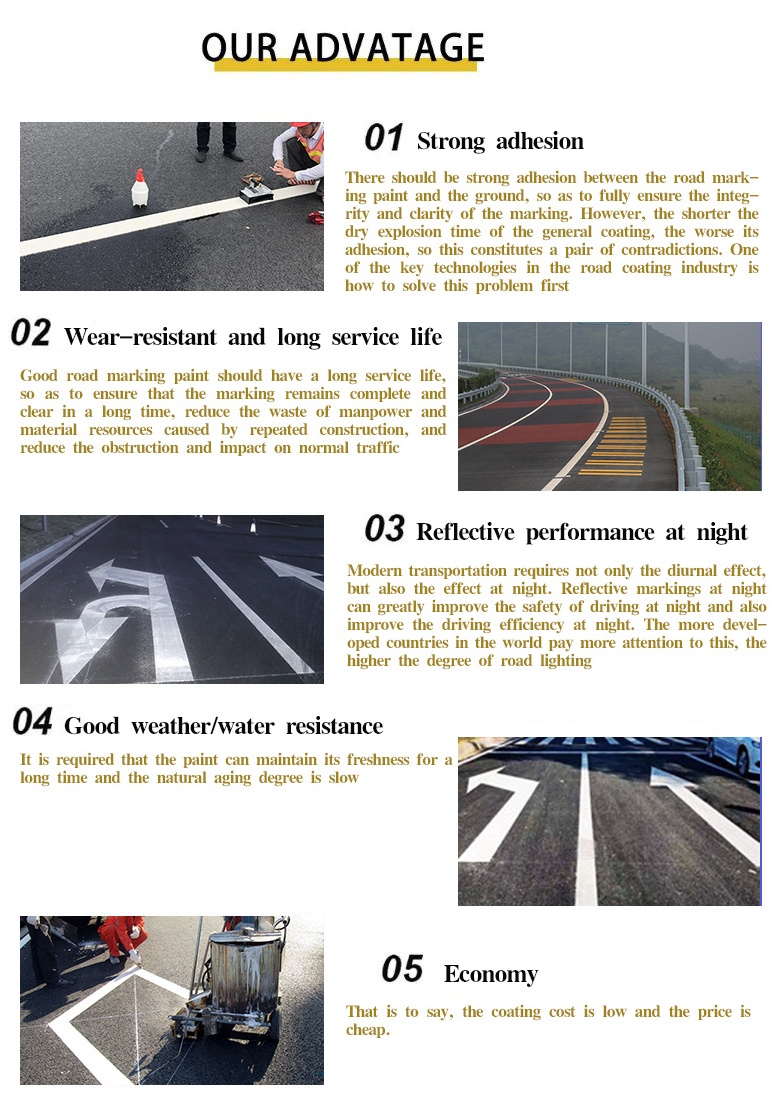

Advantage

Hot-melt road marking coating uses the thermoplasticity of synthetic resin to make the hot-melt coating have quick-drying

property, and the hot-melt property of synthetic resin is used to make the marking and pavement firmly bonded. Hot melt reflective road marking coatings are generally composed of thermoplastic resins, fillers, reflective materials and other additives. Hot melt coatings are powdery at room temperature. There is no solvent volatile component in the composition. It is melted by construction heating, then coated on the ground with specialized equipment and solidified into a film by physical cold condensation. For hot melt road coating, its fluidity is a very important technical index in the construction process.

Hot Searches