NaN / 0

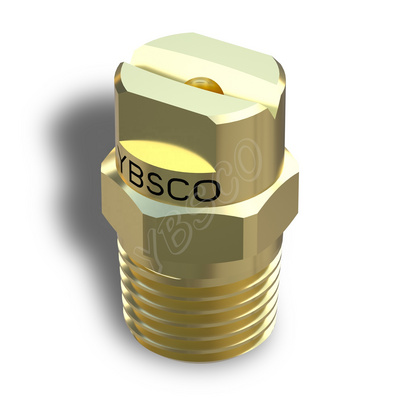

BSPT NPT Water Cleaning Nozzle Plastic Flat Fan Spray Nozzle

Get Latest Price

US$ 0.1

≥10 Pieces

Quick Details

Weight (KG):

0.01

Place of Origin:

Taiwan

Brand Name:

DFK

Product name:

BSPT NPT Water Cleaning Nozzle Plastic Flat Fan Spray Nozzle

Product Details

BSPT NPT Water Cleaning Nozzle Plastic Flat Fan Spray Nozzle

PRODUCT DESCRIPTION

FEATURES

-The spraying type is fan type, and the spray shape is single line and two sides are tapered (tapered edge), which presents a bell curve shape flow field distribution with weaker ends compared to the middle.

-Two piece nozzle design which includes nozzle and the body allows quick and accurate installation by hand. It is convenient for on-site management. Nozzle tip is secured into the body and fastened by three buckle points to avoid the nozzle tip loosening and ensure the performance quality.

-The internal gaskets have different options such as EPDM, Viton and FEPM, which can be adapted to various chemical processes. With a special structural design, the nozzles and the base can be closely fitted to avoid water leakage.

-These general-purpose nozzles without guaranteed flow and angle tolerance are not recommended for environments with high accuracy requirements.

-Recommended working pressure: 3.0 kgf/cm²

-Flowrate tolerance: ± 10% @ 3.0 ± 0.1 kgf/cm²

-Angle tolerance: ± 10° @ 3.0 ± 0.1 kgf/cm²

-Jet angle tolerance: ± 3°

SPRAY PATTERN & FLOW DISTRIBUTION

TECHNICAL DATA

|

Thread

(BSPT)

|

Size (mm)

|

|

|

Weight (g)

|

|

|||

|

|

A

|

B

|

C

|

S303

|

S316

|

|||

|

1/4"Male

|

31.5

|

30.5

|

44.2

|

7.9

|

-

|

|||

|

3/8"Male

|

31.5

|

30.5

|

44.2

|

12.1

|

39.5

|

|||

APPLICATION

● Cleaning: Vehicles, Containers, Filters, Dust, Gravel, Metals, Metal Parts, Mechanical, Steel Plates, Various Containers etc.

● Cooling: gas, tank, machinery, metal, roof etc.

● Dispersion: Humidifying, Chemicals (etching solution, developer, insect repellent, etc.), Water Curtain (fire, dust, deodorisation, etc.)

● Printed circuit board: etching process, developing process, washing process.

DFK INDUSTRIAL CORPORATION

DFK Industrial Corp. was founded in 2011, an OEM/ODM CNC machining precision turning parts manufacturer who provides parts,assembly and integrated solution for our customers.

We have two factories: one is in Taipei, and the other is in Chang Hua(Central of Taiwan). Both factories produce precisely machined parts with efficient Japanese CNC machines such as Star, Citizen,Takamaz and Tsugami.DFK has built a reputation in supplying precision machined components both economically and efficiently.

With our in-houseCitizen/Star/Takamaz technology, we are able to offer Prototype, small batch work for approval prior to mass production. We alsoaccept contracts in small quantity from case to case.

With our in-houseCitizen/Star/Takamaz technology, we are able to offer Prototype, small batch work for approval prior to mass production. We alsoaccept contracts in small quantity from case to case.

Our high standard quality system allows us to control and maintain strict quality requirements for all customers, especially to fulfill the commitments required by ISO 9001.

Our quality system brings confidence to our customers. We document every quality inspection record for our internal evaluation and for traceability.

We have an in-house inspection line including precision hand inspection tools, gauges, micrometers, roughness tester, heightgauges, pin gauges and more.

DFK is dedicated to achieving customer's most satisfaction.ISO standards make a positive difference to all of us, it's not only aquality standard for the operation, it also gives positive influences on our daily lives, and then extending to our society.

We have an in-house inspection line including precision hand inspection tools, gauges, micrometers, roughness tester, heightgauges, pin gauges and more.

DFK is dedicated to achieving customer's most satisfaction.ISO standards make a positive difference to all of us, it's not only aquality standard for the operation, it also gives positive influences on our daily lives, and then extending to our society.

TESTING EQUIPMENTS

Certificate

Packaging & Shipping

Contact Us

FAQ

1. Who are we?

We are based in Taiwan, China, start from 2011,sell to Western Europe(45.00%),Eastern Asia(40.00%),North America(10.00%),Mid East(5.00%).

There are total about 101-200 people in our office.

2. How can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3. What can you buy from us?

CNC turning parts,CNC milling parts,CNC precision parts,Plastic parts,Die-casting parts

4. Why should you buy from us not from other suppliers?

DFK was founded in 1988, Taiwan manufacturer. (www.dfk-cnc.com.tw) Provide hydraulic hose fitting, assemblies, and services. Specializes in stainless steel: 303, 304, 316 and 316L More than 10,000 standard items.

5. What services can we provide?

Accepted Delivery Terms: EXW;

Accepted Payment Currency:USD,EUR,JPY;

Accepted Payment Type: T/T;

Language Spoken:English,Chinese,Japanese

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

We are based in Taiwan, China, start from 2011,sell to Western Europe(45.00%),Eastern Asia(40.00%),North America(10.00%),Mid East(5.00%).

There are total about 101-200 people in our office.

2. How can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3. What can you buy from us?

CNC turning parts,CNC milling parts,CNC precision parts,Plastic parts,Die-casting parts

4. Why should you buy from us not from other suppliers?

DFK was founded in 1988, Taiwan manufacturer. (www.dfk-cnc.com.tw) Provide hydraulic hose fitting, assemblies, and services. Specializes in stainless steel: 303, 304, 316 and 316L More than 10,000 standard items.

5. What services can we provide?

Accepted Delivery Terms: EXW;

Accepted Payment Currency:USD,EUR,JPY;

Accepted Payment Type: T/T;

Language Spoken:English,Chinese,Japanese

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

Hot Searches