NaN / 0

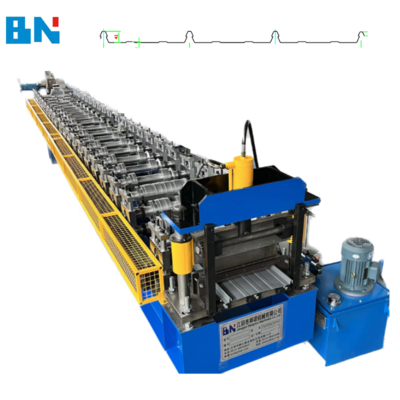

High Speed Corrugated Panel Roll Forming Machine Metal Wall Siding Sheet Making Machine

Get Latest Price

US$ 35000

≥1 Sets

US$ 30000

≥3 Sets

Quick Details

Type:

Tile Forming Machine

Tile Type:

Colored Steel

Production Capacity:

15-20m/minute

Rolling thinckness:

0.3-0.8mm

Product Details

Building Material Wall Panel Metal Roofing Corrugated Color Steel Roll Forming Machine For Sale

Product Description

(1) Brief Introduction

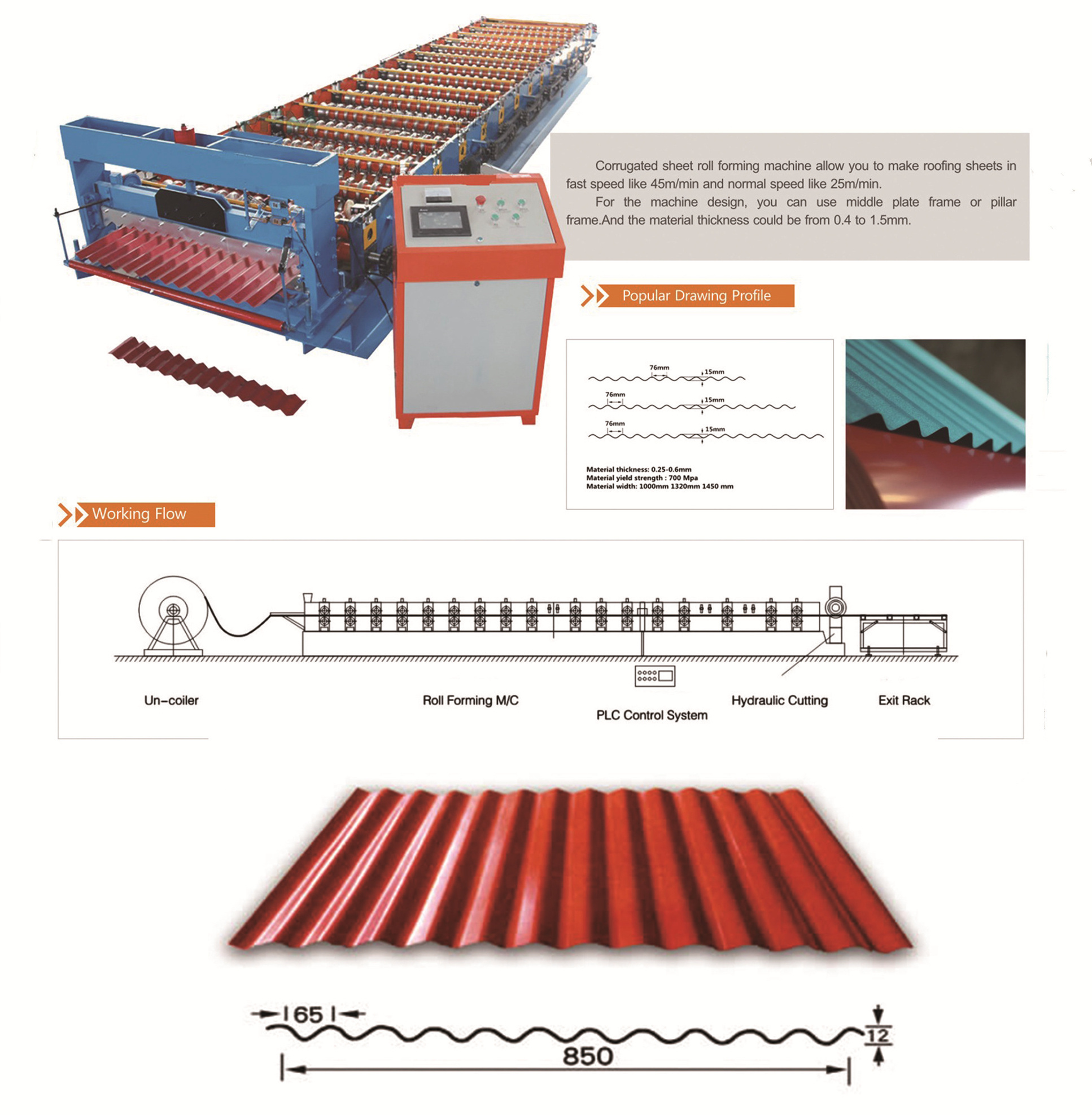

Different roof panel forming machines can produce different shapes of steel roof wall sheets according to the client’s profile drawings and requirements. The steel roof, wall sheets are new building materials with various thickness and colors. The finished products are used as the roof and walls of gymnasiums, airports, theaters , factories, warehouses, garages, exhibition centers etc.

|

1.Suitable material |

Color steel sheet , galvanized steel sheet,aluminum sheet |

|

2.Installation Dimension (L*W*H): |

5.0 m*1.4m*1.2m |

|

3.Main motor power |

3KW with Cycloidal reducer |

|

4.Hydraulic station power |

3KW |

|

5. Hydraulic oil pump |

CB-E 310 |

|

6.Thickness of material |

0.3mm~0.8mm |

|

7.Diameter of principal axis |

Φ70mm |

|

8.Material expand width |

1000,1200,1250mm |

|

9.Electric tension |

380V 3phase 50HZ or as the customer's requirements |

|

10.Material of roller |

High grade 45# forged steel plated with hard chrome plating |

|

11.Controlling system |

PLC |

|

12.Processing speed |

8-12m/min |

|

13.Processing precision within |

1.00mm (depend on design) |

|

14.Material of cutting blade |

Cr12 mould steel with quenched treatment |

|

15.Kind of drive |

0.6 inch chain link bearing model 6210 |

|

16.Roller station |

9Rollers |

|

17.Roller material |

high grade 45#steel; Cr12 quenching |

|

18. Leak frame load-bearing |

4.6T |

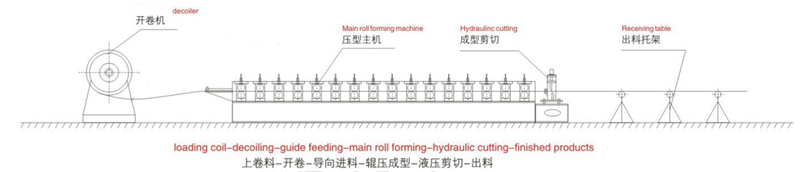

(2) Working Flow of Roll Forming Machine

Decoiling the sheet-Sheet guiding-Roll forming-Measure length-Cutting the panel-Panels to the supporter.

(3) Drawing Profile

Hot Searches