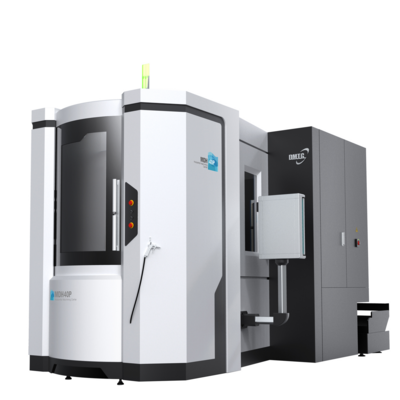

Using HT300 resin sand casting, internal stress is eliminated after two aging treatments, with good stability and high strength. Having a larger guide rail span and stronger overall rigidity. The product has excellent dynamic and static performance, which can meet the needs of high-precision and high stability processing.