NaN / 0

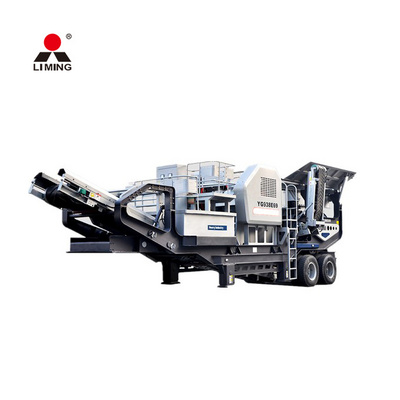

Diesel Mobile Portable Rock marble granite aggregate Crushing Plant Prices quarry production line Stone Jaw Crusher Machine Sale

Get Latest Price

US$ 3000

≥1 Sets

US$ 2800

≥2 Sets

US$ 2000

≥10 Sets

Quick Details

Application:

Small crushing plant, Mining Quarry Building Construction

Place of Origin:

Henan

Brand Name:

Unique

Dimension(L*W*H):

1160*1300*1240

Product Details

Product Description

A jaw crusher uses compressive force for breaking of particle. This mechanical pressure is achieved by the two jaws of the crusher of which one is fixed while the other reciprocates. A jaw or toggle crusher consists of a set of vertical jaws, one jaw is kept stationary and is called a fixed jaw while the other jaw, called a swing jaw, moves back and forth relative to it, by a cam or pitman mechanism, acting like a class II lever or a nutcracker. The volume or cavity between the two jaws is called the crushing chamber. The movement of the swing jaw can be quite small, since complete crushing is not performed in one stroke. The inertia required to crush the material is provided by a weighted flywheel that moves a shaft creating an eccentric motion that causes the closing of the gap.

Features of Diesel engine stone crusher

1. Deep crushing cavity, no dead zone, increasing capacity and output of the feeding;

2. Large crushing ratio, uniform products particle size;

3. Pad-style nesting population adjustment devices, and ease of adjustment range,which increase the flexibility of the equipment;

4. Safe and reliable lubrication system, convenient replacement parts, small maintenance workload;

5. Simple and reliable structure,low operation costs;

6. The discharging size of jaw crusher can be adjusted to meet the requirements of different users;

7. Low noise and less dust;

Specification of Diesel engine stone crusher

| Model |

Feed Opening (mm) |

Max Feed Size (mm) |

Discharging Range Size (mm) |

Capacity (t/h) |

Motor Power (t) |

Weight (kg) |

| PE-150*250 | 150*250 | 125 | 10-40 | 1-3 | 5.5 | 0.8 |

| PE-250*400 | 250*400 | 210 | 20-60 | 5-20 | 15 | 2.8 |

| PE-400*600 | 400*600 | 340 | 40-100 | 16-60 | 30 | 6.5 |

| PE-500*750 | 500*750 | 425 | 50-100 | 40-110 | 55 | 10.6 |

| PE-600-900 | 600*900 | 500 | 65-180 | 80-180 | 55 | 15.5 |

| PE-750*1060 | 750*1060 | 630 | 80-180 | 110-320 | 110 | 28 |

| PE-800*1060 | 800*1060 | 680 | 100-200 | 140-340 | 110 | 30 |

| PE-870*1060 | 870*1060 | 750 | 170-270 | 180-360 | 110 | 30.5 |

| PE-900*1060 | 900*1060 | 780 | 200-290 | 200-380 | 110 | 31 |

| PE-900*1200 | 900*1200 | 780 | 95-225 | 220-450 | 132 | 49 |

| PE-1000*1200 | 1000*1200 | 850 | 195-280 | 280-550 | 132 | 51 |

| PE-1200*1500 | 1200*1500 | 1020 | 150-300 | 400-800 | 160 | 100.9 |

| PEX-150*750 | 150*750 | 120 | 18-48 | 8-25 | 15 | 3.5 |

| PEX-250*750 | 250*750 | 210 | 25-60 | 13-35 | 22 | 4.9 |

| PEX-250*1000 | 250*1000 | 210 | 25-60 | 16-52 | 30 | 6.5 |

| PEX-250*1200 | 250*1200 | 210 | 25-60 | 20-61 | 37 | 7.7 |

| PEX-300*1300 | 300*1300 | 250 | 20-90 | 25-95 | 75 | 11 |

Detailed Images

Packaging & Shipping

Packaging: Standard Container Packs or in Bulk.

Shipping: we deliver the cargo to China's main sea ports,such as Qingdao,Tianjin,Shanghai etc.And then the container will be transported to your country by sea.

Our Services

After-sale service of jaw stone crusher

1.more than 12 months' warranty period

2.Erection and Commissioning

3.Operator Training

4.Spare Parts Supply

Hot Searches