NaN / 0

Tomato peeling machine tomato paste sauce production processing line

Get Latest Price

US$ 10000

≥1 Sets

Quick Details

Raw material:

Vegetables, Fresh tomato

Place of Origin:

Henan, China

Application:

Tomato Mango Kiwifruit Strawberry

Name:

Fruit Juicer Production Line

Product Details

Tomato peeling machine tomato paste sauce production processing line

Product Description

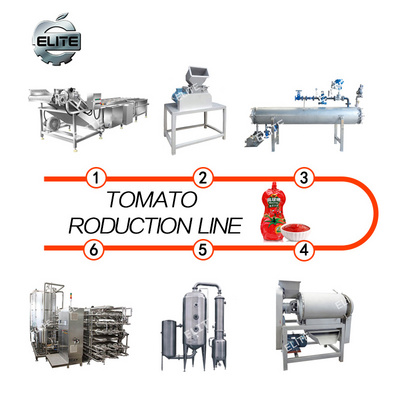

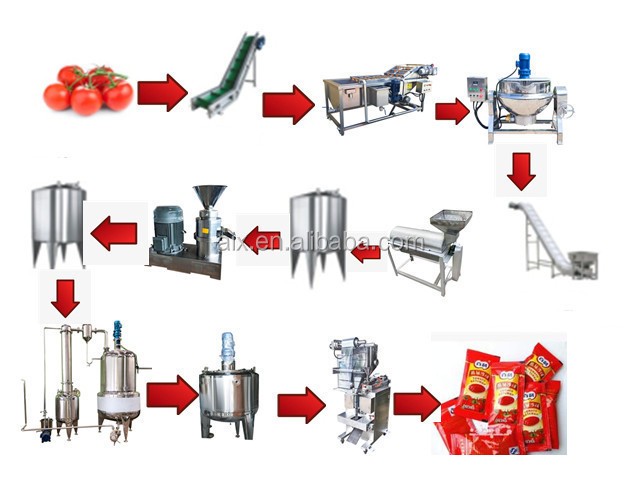

The main equipment of the tomato paste production line consists of a washing machine, a cooking pot, a beater, a colloid mill, a vacuum concentrator, a cooling mixer, a temporary storage tank, and a filling machine.The biggest special feature of our company's tomato paste production line is that it contains a vacuum concentrator, which produces a high concentration of tomato paste, good taste and long shelf life.

Our company supports 200-5000kg per hour tomato paste production line.

Production Process

Raw material cleaning → blanching → beating → grinding → heating and concentration → sterilization → cooling → finished product

Introduction to main machine functions

|

01 . Bubble cleaner, its function is to clean fresh tomatoes to ensure the clean and hygienic production of tomato paste . |

|

02. Electric heating cooking pot, his role is to peel the ketchup and reduce the impurities in the tomato sauce. |

|

|

03. Tomato beater. Preliminary preparation of tomato puree. |

|

|

04. Colloid mill, its role is to grind tomato puree. |

|

|

04. Vacuum concentrator. This machine can evaporate excess water from the ketchup to the desired concentration and get the final ketchup. He also has a bactericidal effect, which improves the shelf life of the ketchup and improves the taste of the ketchup. |

|

|

05. Cool the mixer and stir and cool the concentrated tomato sauce. |

|

|

06. Filling machine, filling the cooled ketchup. We also have bottle filling machines. |

Final product show

Case show

Our company provides Togo with the first line of pineapple juice installed in Togo.Received high praise from the leadership of the Togolese government. The picture shows the government leaders visiting the production site.

The first tomato paste production line in Togo is provided by our company. The picture shows the customer coming to our factory for a field visit.

Packaging & Shipping

Hot Searches