NaN / 0

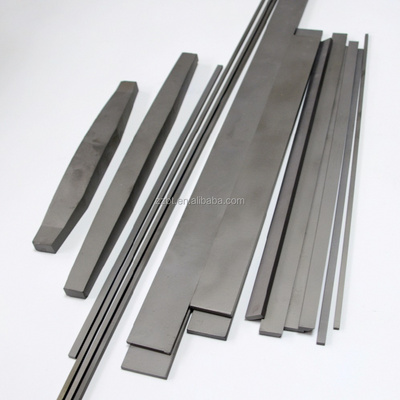

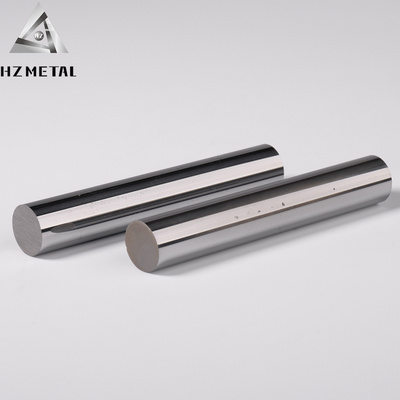

YG6 YG8 Solid Tungsten Carbide Rod Cemented Carbide Bar in Length 10-330 mm

Get Latest Price

US$ 60

≥10 Kilograms

US$ 58

≥100 Kilograms

US$ 55

≥1000 Kilograms

Quick Details

Alloy Specification:

YU06/YG6X/YL10.2/JZ401/YG15

Place of Origin:

Hunan, China

Brand Name:

HZ-metal

Model Number:

YL10.2

Product Details

Product Overview

Tungsten Carbide is often referred to as a Hard Metal due to it’s very high hardness in relation to other metals. Typically a Tungsten Carbide can have a hardness value of 1600 HV, whereas mild steel would be in the region of 160 HV a factor of 10 lower. Tungsten Carbide Rods are used for cutting aluminum alloy, cast iron, stainless steel, refractory alloy steel, nickel based alloy, titanium alloy and nonferrous metals. With several years’ development, with our good quality and competitive price, our products have been widely recognized by worldwide makers of cutting tools. We are looking forward to establish new business with new customers.

Product Description

Tungsten carbide rods used in make the drill bits, end-mills, reamers, automobile special cutters, printed circuit board special cutters, engine special cutters, horologe processing special cutters, integral vertical milling cutter, graver and etc.

Besides, they can bu used for making of cemented carbide stamping head, core bar and perforation tools. Both sintered blanks and ground tungsten carbide rod are supplied.

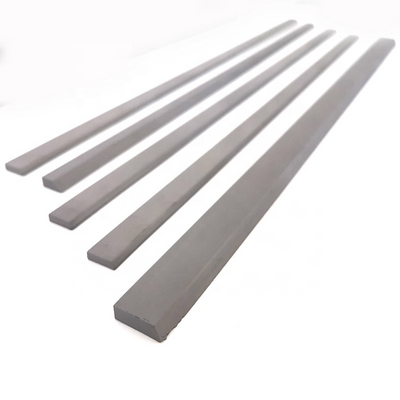

Tungsten rod surface color classification:

1. The surface of the sintered tungsten rod is silver-gray metallic luster.

2. There is a layer of oxide on the surface of the forged tungsten rod, and the surface is black.

3. Polished tungsten rod with silver-gray metallic luster.

Tungsten Carbide Rods Performances:

1. 100% virgin tungsten carbide raw material

2. With strict tolerance extent control

3. Excellent wear resistance & high toughness, good performance

4. Have very good thermal & chemical stability

5. Anti-deformation & deflection

6. A special Hot Isostatic Press (HIP) process

7. Customized order is welcomed.

PRODUCT SPECIFICATIONS

|

Grade

|

ISO

|

Cobalt content(%)

|

Hardness (HRA)

|

Density (g/cm³)

|

T.R.S (ISO3327)

|

WC Grain size(μm)

|

Application recommended

|

|

YU06

|

K05-K10

|

6%

|

94.0

|

14.75

|

3700

|

0.4-0.5

|

Suitable for machining aluminum-magnesium alloys, glass fiber, carbon fiber, wood, harden plastic, etc. It is recommended for making PCB micro tools and other material drills.

|

|

YG6X

|

K05-K10

|

6%

|

92.5

|

14.92

|

3000

|

0.7-0.9

|

Suitable for machining chilled alloy cast iron, heat-resistane alloy steel, non-ferrous metal, wood, paper, plastic and aluminum-magnesium, etc. It is recommended for making solid carbide drills, milling and reamers.

|

|

YL10.2

|

K20-K30

|

10%

|

91.8

|

14.45

|

3800

|

0.7-0.9

|

Suitable for machining carbon steel, cast iron, stainless steel, heat-resistance steel is recommended for making different

specification tools, such as drills, end mills, screw taps, rotating file A good material for general-purpose. |

|

JZ401

|

K30-K40

|

12%

|

92.0

|

14.15

|

4000

|

0.5-0.7

|

Suitable for machining nickel based alloy, titanium alloy, stainless steel, mould steel, chilled hardened steel and grey cast

iron, etc. It is recommended for making milling tools and reamers, for high speed machining. |

|

YG15

|

K30-K40

|

15%

|

87.6

|

14.00

|

4000

|

1.2-1.4

|

Suitable for making solid mould dies and tools for punching operation.

|

|

Diameter

|

h5

|

h6

|

h7

|

|

0-0.3 mm

|

0.004 mm

|

0.006 mm

|

0.010 mm

|

|

0-0.11811 in.

|

0.00015 in.

|

0.00024 in.

|

0.00039 in.

|

|

3.001-6.0 mm

|

0.005 mm

|

0.008 mm

|

0.012 mm

|

|

0.11812-0.23622 in.

|

0.00020 in.

|

0.00031 in.

|

0.00047 in.

|

|

6.001-10.0 mm

|

0.006 mm

|

0.009 mm

|

0.015 mm

|

|

0.236237 in.

|

0.00024 in.

|

0.00035 in.

|

0.00059 in.

|

|

10.001-17.0 mm

|

0.008 mm

|

0.011 mm

|

0.018 mm

|

|

0.39371-0.70866 in.

|

0.00031 in.

|

0.00043 in.

|

0.00071 in.

|

|

18.00-30.0 mm

|

0.009 mm

|

0.013 mm

|

0.021 mm

|

|

0.90867-1.18110 in.

|

0.00035 in.

|

0.00051 in.

|

0.00083 in.

|

|

30.001-50.0 mm

|

0.011 mm

|

0.016 mm

|

0.025 mm

|

|

1.81111-1.96850 in.

|

0.00043 in.

|

0.00063 in.

|

0.00098 in.

|

Product application

Tungsten carbide Rod

is suitable for the production of various types electrical machine & electronic progressive dies and punches. And widely used in ceramics, printing machine, plastic, rubber, leather industry and cutting machines, CNC machine, CNC, PCB micro drill bits, etc.

It also can be used for preparing high purity tungsten rod or wire, or for high performance electrode, heating element or high temperature parts in the fields of national defense and military weapons, precision electronic industry and other precision technology and materials.

Used for

1.High speed cutting tools,

2. Drill bits, end mills, reamers.

3. Stamping and measuring tools.

4. Paper making, packaging, printing, and non-ferrous metal processing industries.

5. Carbide milling cutter, carbide cutting tools, carbide drill, milling cutter core bit,

6. electronic tools, ladder drill, metal cutting saw, diamond, guns, Angle cutter, carbide rotary

file,Carbide tool.

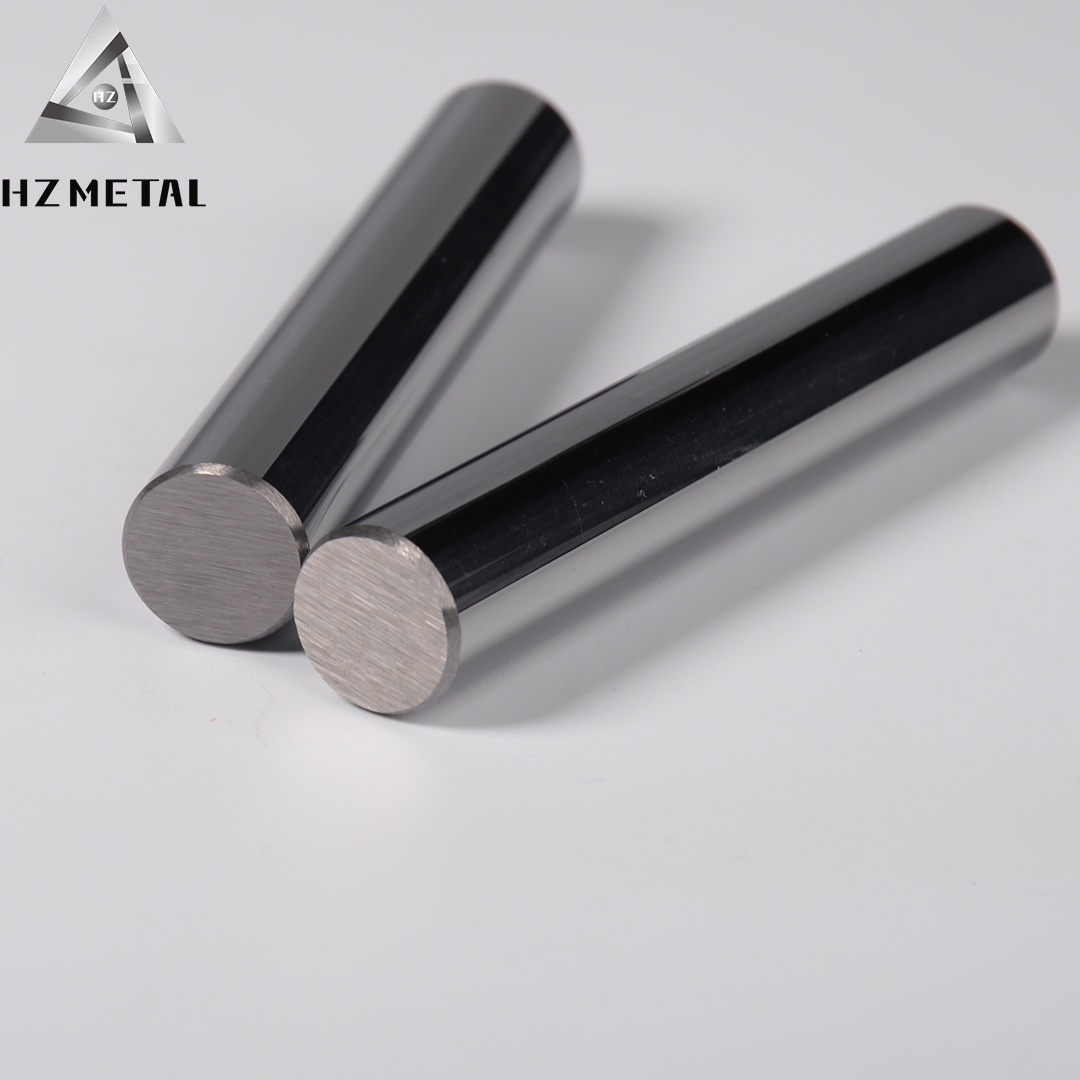

Our Advantages

1.Extrusion rods and HIP sintering.

2.Ultrafine grain size powders.

3.Run-out and Roundness can be less than 5 micron(0.005mm).

4.Carbide rods is solid or with straight/helix coolant holes.

5.Can reach a mirror effect surface after accurate grinding and polishing.

Hot Searches