NaN / 0

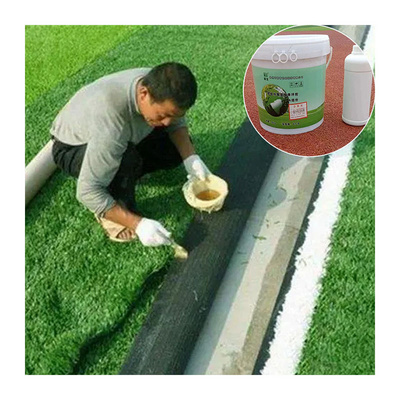

Polyurethane adhesive glue for landscape artificial grass and synthetic turf installation

Get Latest Price

US$ 1

≥1 Pieces

Quick Details

CAS No.:

7085-85-0

Other Names:

synthetic turf adhesive

MF:

-CHNO--

EINECS No.:

210-898-8

Product Details

China polyurethane sealant for artificail grass installation

1. Description

Flexibond 8260 is a two component polyurethane adhesive used for synthetic turf backing sheet bonding which plays the role of anchoring and protection of the grass.

2. Characteristics

(1) Long pot life under room temperature, cures fast when heating, improve the production efficiency

(2) Slight foaming, good flexibility, resistant to bending

(3) High drawing strength, low adhesive consumption, low comprehensive cost

(4) Good flexibility, resistant to bending

(5) High gloss

(6) Resistant to water, acid, alkali and salt aging

3.Technical Data

| Flexibond 8260 | Flexibond 8200 | |

| Color | Black | Brown |

| Color after mixing | Black | |

| Viscosity |

8000-15000mpa.s

Brookfield - RVT 5/20 |

200-250mpa.s

Brookfield - RVT 2/20 |

| Viscosity (after mixing) |

3000-6000mpa.s

Brookfield - RVT 6/20 |

|

| Mixing ratio (by weight) | 6.5 | 1 |

| Pot life (23ºC) | 30-50mins (can be adjusted) | |

| Cure rate (120ºC oven) | 2-5mins (can be adjusted) | |

| Shelf life (unopened below 25ºC) | 12 months | 6 months |

*Testing temperature 23ºC and 50% RH

4. Usage

(1) Preparation

Mix the resin and the hardener in the mixing machine. The adhesive should keep a constant temperature (recommended temperature 25-35ºC) in the mixing machine to ensure the applying stability. The mixing ratio should be corrected with the mixing machine before starting application.

Note: Sediment in the resin is normal. Mix the resin uniformly before using.

(2) Substrate Surface Treatment

The substrate surface should be clean and dry, free of grease, dust and other contaminations.

(3) Mixing ratio

Flexibond 8260: Flexibond 8201=6.5-8.5:1 by weight.

The mixing ratio varies with the different requirements of adhesive consumption and hardness. If the adhesive consumption is low, in order to achieve a high drawing strength, we recommend mixing ratio 6.5:1; if the adhesive consumption is high, in order to achieve a good flexibility, we recommend mixing ratio 8.5:1. For details, please consult Comens technical department.

Stir uniformly component A before using it. Mix the two components strictly according to the ratio. Mix for 1-2 more minutes after the adhesive color is uniform.

(4) Adhesive Coating

The adhesive consumption is 500-1000g per square meter. The consumption varies with the substrates surface structures and different performance requirements. The mixed adhesive should be used up within its pot life.

(5) Curing and Curing Time

The substrates coated with the adhesive needs to be cured. The turf sheet should be rolled after the adhesive surface tack free. The curing rate varies with the temperature. The lower the temperature is, the longer the curing time it takes. The higher the temperature is, the shorter the curing time it takes. Under the temperature 120ºCin the oven, the curing takes 2-5 minutes.

(6) Cleaning

Recommended cleaning solvent: methylene dichloride, ethyl acetate.

5.Packaging

Component A (Resin): 1625kg/drum

Component B (Hardener): 250kg/drum

The packaging can be adjusted according to customer's requirement.

6.Note

(1) The adhesive sealant should be used up once mixed. The remaining sealant cannot be used if viscosity appears too high.

(2) Do not apply the product together with other adhesives. Please enquire to our technicians if you have such a need.

(3) The information and recommendations related to the application and end-use of COMENS' products are given in good faith based on COMENS' current knowledge and experience of the products when properly stored, handled and applied under normal conditions. This information must on no account be used as a substitute for necessary prior tests which alone can ensure that a product is suitable for a given use, due to the practical differences in materials, substrates and actual site conditions. Users are requested to check that they are in possession of the latest version of this documents and COMENS' is at their disposal to supply any additional information.

Hot Searches